This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

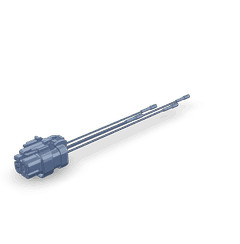

The Electrical Repair Connector 2892374, manufactured by Cummins, is a specialized component designed for the maintenance and repair of electrical systems in commercial trucks. Cummins, a well-established name in the commercial truck industry, is known for its commitment to quality and innovation. This connector plays a significant role in ensuring the reliability and efficiency of electrical systems in heavy-duty vehicles.

Basic Concepts of Electrical Repair Connectors

Electrical repair connectors are components used to join or repair electrical circuits. They facilitate the maintenance and repair of electrical systems by providing a secure and reliable connection between wires or other electrical components. These connectors are essential for restoring functionality to damaged or worn-out electrical systems, ensuring that vehicles operate efficiently and safely 1.

Purpose of the 2892374 Electrical Repair Connector

The 2892374 Electrical Repair Connector is specifically designed to address the needs of commercial truck electrical systems. It plays a role in the repair and maintenance of these systems by providing a robust and dependable connection. This connector is used to replace damaged or corroded sections of wiring, ensuring that the electrical system remains intact and functions correctly. By facilitating quick and effective repairs, it helps minimize downtime and maintain the operational integrity of commercial trucks.

Key Features

The 2892374 Electrical Repair Connector boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-lasting performance. The design includes robust terminals that provide a secure connection, reducing the risk of electrical faults. Additionally, the connector is engineered to withstand the harsh environments typical of commercial truck operations, making it a reliable choice for heavy-duty applications 2.

Benefits of Using the 2892374 Electrical Repair Connector

Using the 2892374 Electrical Repair Connector offers several advantages. Its high-quality construction ensures improved reliability, reducing the likelihood of electrical failures. The ease of installation makes it a convenient option for maintenance professionals, saving time during repairs. Furthermore, the durability of the connector can lead to potential cost savings by reducing the frequency of repairs and replacements 3.

Installation and Usage Guidelines

Proper installation of the 2892374 Electrical Repair Connector involves several steps. Begin by identifying the damaged section of the wiring that requires repair. Strip the insulation from the wires to expose the conductors. Insert the stripped wires into the connector terminals, ensuring a secure fit. Use the appropriate tools to crimp the terminals, creating a strong and reliable connection. Finally, inspect the connection to confirm that it is secure and free from defects. Always observe safety precautions, such as wearing protective gloves and ensuring the electrical system is de-energized before beginning work.

Troubleshooting Common Issues

Common issues with electrical repair connectors may include poor connections, corrosion, or damage to the terminals. To troubleshoot these problems, first, inspect the connector for signs of wear or corrosion. If corrosion is present, clean the terminals using a suitable cleaner and a wire brush. Ensure that the wires are properly inserted and crimped. If the connector is damaged, replace it with a new one to restore the integrity of the electrical system.

Maintenance Tips

Regular maintenance of the 2892374 Electrical Repair Connector is important to ensure optimal performance and longevity. Inspect the connector periodically for signs of wear, corrosion, or damage. Clean the terminals as needed to remove any buildup that could affect the connection. If any issues are detected, address them promptly to prevent further degradation. Following these maintenance practices will help ensure that the connector continues to provide reliable service.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for quality, innovation, and reliability. The company is committed to advancing technology and providing solutions that meet the needs of its customers in the commercial truck industry and beyond 4.

Role of Part 2892374 Electrical Repair Connector in Engine Systems

When addressing the integration of Part 2892374 Electrical Repair Connector within engine systems, it is important to understand its function in maintaining the integrity and efficiency of electrical connections. This component is instrumental in the repair and maintenance of the wiring harness, which is a network of wires that transmit electrical signals and power to various engine components.

Integration with Wiring Harness Repair Kit

The Electrical Repair Connector, Part 2892374, is designed to interface seamlessly with wiring harness repair kits. Its primary role is to facilitate the restoration of damaged or worn-out sections of the wiring harness. By providing a secure and reliable connection point, it ensures that electrical signals are transmitted without interruption, which is vital for the proper functioning of engine systems.

Enhancing System Reliability

Incorporating Part 2892374 into the repair process enhances the overall reliability of the engine’s electrical system. It allows for quick and efficient repairs, minimizing downtime and reducing the risk of further damage to the wiring harness. This is particularly important in high-stress environments where the wiring harness is subject to vibrations, heat, and mechanical wear.

Supporting Diagnostic and Maintenance Procedures

The use of Part 2892374 in conjunction with wiring harness repair kits supports diagnostic and maintenance procedures by providing a consistent and dependable connection point. This facilitates easier troubleshooting of electrical issues, as technicians can isolate problems to specific sections of the wiring harness and make targeted repairs.

Facilitating Upgrades and Modifications

Moreover, Part 2892374 Electrical Repair Connector plays a role in facilitating upgrades and modifications to engine systems. Whether it is integrating new sensors, upgrading to more efficient wiring, or modifying existing circuits, this component ensures that connections remain secure and functional throughout the process.

Conclusion

In summary, Part 2892374 Electrical Repair Connector is a vital component in the maintenance and repair of engine systems, particularly when working with wiring harness repair kits. Its role in ensuring secure and reliable electrical connections contributes to the overall performance and longevity of engine components.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Minaker, B. P. (2019). Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.