This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

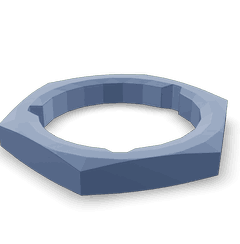

The 2892376 Electrical Connector Nut, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Its primary function is to secure electrical connections within the truck’s electrical system, ensuring reliable performance and safety. Cummins, a well-established name in the automotive industry, is known for its commitment to producing high-quality components that meet the demanding requirements of commercial vehicles 1.

Basic Concepts of Electrical Connector Nuts

An Electrical Connector Nut is a fastener used to secure electrical connections. It plays a role in the electrical system by providing a stable and secure connection between wires and terminals. This ensures that electrical signals and power are transmitted efficiently and reliably. The nut helps prevent issues such as loose connections, which can lead to intermittent electrical problems or complete failure of electrical components 2.

Role of the 2892376 Electrical Connector Nut in Truck Operation

This Cummins part is integral to the electrical system of a truck. It secures connections in various electrical circuits, including those for lighting, sensors, and control systems. By maintaining reliable electrical connections, it contributes to the overall functionality and safety of the vehicle. Proper installation and maintenance of this nut are important for ensuring that the truck’s electrical systems operate correctly.

Key Features of the 2892376 Electrical Connector Nut

The 2892376 is designed with several features that enhance its performance. It is constructed from high-quality materials that provide durability and resistance to corrosion. The nut features a specific thread type that ensures a secure fit on electrical terminals. Additionally, it may include unique attributes such as a locking mechanism to prevent loosening over time, which is particularly beneficial in the vibrating environment of a commercial truck.

Benefits of Using the 2892376 Electrical Connector Nut

Using this part offers several advantages. Its design promotes improved electrical conductivity, ensuring that connections are efficient and reliable. The material composition provides resistance to corrosion, which is important in the harsh environments often encountered by commercial trucks. Additionally, the nut is designed for ease of installation, allowing for quick and secure fastening of electrical connections.

Installation and Usage Guidelines

To install the 2892376, follow these steps: First, ensure that the electrical terminal is clean and free of corrosion. Next, align the nut with the terminal and begin threading it on. Use a torque wrench to tighten the nut to the specified torque, ensuring a secure connection without over-tightening. It is also important to periodically check the connection to ensure it remains secure, especially after the truck has been in operation for some time.

Maintenance and Troubleshooting Tips

Routine maintenance of the 2892376 involves inspecting the connection for signs of corrosion or loosening. If corrosion is present, clean the terminal and nut with a suitable cleaner before re-tightening. Common issues may include intermittent electrical problems, which can often be traced back to a loose or corroded connection. Troubleshooting steps include checking the torque of the nut and ensuring that the connection is clean and secure.

Compatibility and Application

The 2892376 is designed for use in specific types of trucks and electrical systems. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Application considerations may include the specific electrical circuits where the nut will be used, as well as any environmental factors that could affect its performance.

Safety Considerations

When working with the 2892376, it is important to follow electrical safety practices. This includes ensuring that the truck’s electrical system is de-energized before beginning work to prevent the risk of electric shock. Proper handling procedures should be followed to avoid damage to the nut or the electrical terminals. Additionally, always use the correct tools and follow torque specifications to ensure a secure and safe connection.

Role of Part 2892376 Electrical Connector Nut in Wiring Harness Repair Kit

This part is integral to the functionality and reliability of the wiring harness repair kit. This component ensures secure connections between various electrical wires and connectors within the kit.

When repairing or maintaining an engine’s electrical system, the Electrical Connector Nut plays a significant role in the following ways:

-

Secure Attachment: It provides a robust attachment point for electrical connectors, preventing them from becoming loose due to vibrations or movement. This stability is essential for maintaining consistent electrical connections.

-

Insulation: The nut helps in insulating the connections, reducing the risk of short circuits. Proper insulation is vital for the safe operation of the engine’s electrical components.

-

Ease of Maintenance: By using standardized nuts like part 2892376, technicians can quickly and efficiently replace or repair connections. This standardization simplifies the maintenance process and ensures that repairs are performed correctly.

-

Compatibility: The nut is designed to work seamlessly with other components in the wiring harness repair kit, ensuring that all parts fit together correctly without the need for additional modifications.

Conclusion

In summary, the 2892376 Electrical Connector Nut is a fundamental component in the wiring harness repair kit, contributing to the overall reliability and performance of the engine’s electrical system. Its role in securing connections, providing insulation, and ensuring ease of maintenance makes it an essential part for any commercial truck’s electrical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.