This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

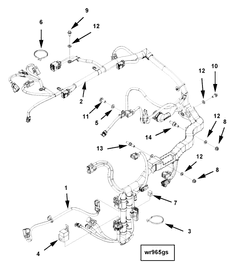

The 2899623 Electronic Control Module Wiring Harness by Cummins is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the electrical connections between the Electronic Control Module (ECM) and various sensors, actuators, and other electronic components within the truck’s system. This wiring harness plays a significant role in ensuring the proper operation and communication between these components, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires, connectors, and terminals that are bundled together to manage the electrical connections in a vehicle’s electronic system. The harness includes various components such as wires of different gauges, connectors, splices, and protective coverings. It functions by providing a structured and organized pathway for electrical signals and power to travel between the ECM and other electronic components, ensuring efficient and reliable communication and operation 1.

Role of the 2899623 Electronic Control Module Wiring Harness in Truck Operation

The 2899623 Wiring Harness plays a specific role in the operation of a truck by establishing and maintaining the electrical connections required for the ECM to communicate with various sensors and actuators. This includes components related to engine management, transmission control, emissions systems, and other critical functions. The harness ensures that data and power are accurately transmitted, allowing the ECM to monitor and adjust the truck’s performance in real-time 2.

Key Features of the 2899623 Wiring Harness

The 2899623 Wiring Harness is designed with several key features that enhance its performance and reliability. These include a robust construction using high-quality materials to withstand the harsh environments typical of commercial truck operations. The harness is engineered to be durable, with protective coverings to shield the wires from abrasion, moisture, and other potential damages. Additionally, it features precise connector placements and secure terminals to ensure reliable connections and minimize the risk of electrical issues 3.

Benefits of Using the 2899623 Wiring Harness

Using the 2899623 Wiring Harness offers several benefits. It provides improved efficiency in the electrical system by ensuring that connections are secure and signals are transmitted without interference. The harness is designed for ease of installation, reducing the time and effort required during maintenance or upgrades. Its reliable construction contributes to the overall durability and performance of the truck’s electronic systems, leading to enhanced operational reliability.

Installation Process

Installing the 2899623 Wiring Harness involves several steps to ensure a secure and effective setup. Begin by identifying the correct location for the harness within the truck’s electrical system. Use the provided connectors to link the harness to the ECM and other components, ensuring that each connection is secure and properly aligned. Tools such as wire strippers, crimping tools, and electrical tape may be required. Follow best practices by double-checking all connections and ensuring that the harness is routed away from moving parts and heat sources to prevent damage.

Troubleshooting Common Issues

Common issues with the 2899623 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by inspecting the harness for any visible signs of wear or damage. Check each connection to ensure it is secure and properly aligned. Use a multimeter to test for continuity and identify any breaks in the wiring. If an issue is detected, repair or replace the affected section of the harness as necessary.

Maintenance Tips

To ensure the long-term performance and reliability of the 2899623 Wiring Harness, regular maintenance is recommended. Inspect the harness periodically for signs of wear, damage, or corrosion. Clean the connectors and terminals to remove any dirt or debris that may affect the connections. Ensure that the harness is properly routed and secured to prevent abrasion or accidental disconnection. Addressing these maintenance tasks will help maintain the integrity of the electrical system and prevent potential issues.

Conclusion

The 2899623 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks, ensuring efficient and reliable communication between the ECM and various electronic components. Its robust design, key features, and benefits contribute to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the effectiveness of this Cummins part.

References

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.