This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

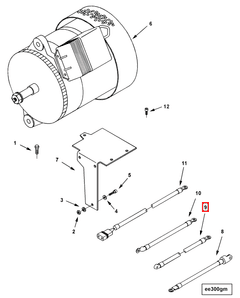

The Cummins 3088251 Electrical Wire is a specialized component designed for use in commercial trucks. It serves a significant role in the electrical system of these vehicles, contributing to the efficient and reliable operation of various truck components. Understanding its purpose and functionality is key to maintaining the overall performance and safety of commercial trucks.

Basic Concepts of Electrical Wires

Electrical wires are conductors that facilitate the transmission of electric current within a vehicle’s electrical system. They are fundamental in powering and controlling various components, from lighting and signaling to engine management systems. Proper wiring is vital for the efficient and safe operation of truck components, ensuring that electrical signals and power are delivered accurately and reliably 1.

Purpose of the Cummins 3088251 Electrical Wire

The Cummins 3088251 Electrical Wire is specifically designed to play a role in the electrical system of a truck. It ensures the proper functionality of connected components by providing a reliable pathway for electric current. This wire is integral to maintaining the electrical integrity of the truck, supporting the operation of critical systems and enhancing overall vehicle performance 2.

Key Features

The Cummins 3088251 Electrical Wire boasts several key features that enhance its performance and durability. These include a specific material composition that ensures conductivity and resilience, a gauge that is appropriate for the intended current load, and insulation type that protects against environmental factors and electrical shorts. Unique design elements may also be present to further improve its functionality in demanding truck applications 3.

Benefits

Using the Cummins 3088251 Electrical Wire offers several advantages. It provides improved reliability in the electrical system, enhanced durability under tough conditions, resistance to environmental factors such as moisture and temperature fluctuations, and contributes to the overall efficiency of the truck’s electrical system. These benefits help ensure that the truck operates smoothly and efficiently.

Installation Considerations

When installing the Cummins 3088251 Electrical Wire, it is important to follow guidelines and best practices to ensure proper integration into the truck’s electrical system. This includes routing the wire correctly to avoid damage and interference, securing it in place to prevent movement and wear, and ensuring compliance with manufacturer recommendations for optimal performance and safety.

Troubleshooting and Maintenance

To maintain the Cummins 3088251 Electrical Wire and ensure its longevity and optimal performance, periodic inspections are recommended. This includes checking for signs of wear, damage, or corrosion. Troubleshooting common issues may involve identifying and repairing breaks or shorts in the wire. Replacement guidelines should be followed when the wire shows significant signs of degradation or failure.

Safety Precautions

Working with electrical wires, including the Cummins 3088251, requires observing certain safety precautions. This involves ensuring that the electrical system is de-energized before beginning work, using appropriate personal protective equipment, and following safety protocols to prevent accidents and ensure personal safety. Adhering to these precautions is vital when handling electrical components.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and innovation. The company has a history of producing reliable and high-performance automotive components, including electrical wires. Cummins’ reputation is built on its dedication to excellence in manufacturing and its ongoing efforts to advance technology in the automotive sector.

Role of Part 3088251 Electrical Wire in Engine Systems

Part 3088251 Electrical Wire is integral to the operation of several key engine components, ensuring efficient and reliable performance.

Alternator and Alternator Kit

In the alternator and alternator kit, the electrical wire facilitates the transfer of electrical power generated by the alternator to the vehicle’s battery and electrical systems. This ensures that the battery remains charged and that all electrical components, such as lights, sensors, and the ignition system, receive a consistent power supply. The wire’s role is to maintain the electrical integrity and efficiency of the alternator system, supporting the overall functionality of the vehicle’s electrical network.

Cooler

For the cooler, particularly in systems where the cooler is part of the engine’s lubrication or transmission system, the electrical wire is used to power the cooling fan or pump. This ensures that the cooling system operates effectively, maintaining optimal temperatures for engine oil or transmission fluid. The wire’s reliable performance is essential for preventing overheating and ensuring the longevity and efficiency of the cooling system.

Torque Converter Oil

In systems involving the torque converter, the electrical wire may be used to power solenoids or sensors that monitor and control the flow of torque converter oil. This is vital for the smooth operation of the transmission, as it ensures that the torque converter engages and disengages correctly, providing seamless power transfer from the engine to the transmission. The electrical wire’s precise function helps in maintaining the transmission’s performance and efficiency.

Conclusion

Overall, the Cummins 3088251 Electrical Wire plays a significant role in ensuring the proper functioning of these engine components by providing the necessary electrical connections and power distribution. Its robust construction, precise engineering, and compatibility with various engine systems make it an essential component for maintaining the electrical integrity and efficiency of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.