This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

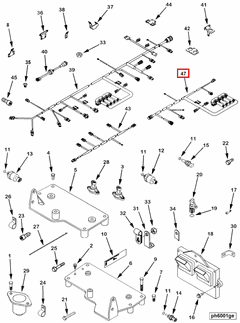

The 3093363 Electronic Control Module Wiring Harness by Cummins is a vital component in the operation of commercial trucks. This wiring harness facilitates the communication between the engine control module (ECM) and various sensors and actuators within the truck’s engine management system. Its purpose is to ensure reliable and efficient operation of the engine by providing a robust and durable connection pathway for electrical signals.

Basic Concepts of Electronic Control Module Wiring Harness

An electronic control module wiring harness is a network of wires and connectors designed to link the ECM with other electronic components in a vehicle. These harnesses play a role in transmitting data and power between the ECM and sensors, actuators, and other control units. They are integral to the vehicle’s electronics and engine management systems, enabling precise control over engine functions and ensuring optimal performance 1.

Function and Operation

The 3093363 Electronic Control Module Wiring Harness operates by providing a structured pathway for electrical signals within the truck’s electrical system. It connects the ECM to various components such as sensors, actuators, and other control modules. This harness allows the ECM to receive data from sensors, process it, and send commands to actuators to adjust engine parameters in real-time. Its design ensures minimal signal interference and maximum reliability under varying operating conditions 2.

Key Features

The 3093363 Electronic Control Module Wiring Harness is characterized by its robust design and high-quality materials. It features durable insulation and corrosion-resistant connectors to withstand the harsh environments typical of commercial truck operations. The harness is engineered to provide reliable performance and longevity, with precise wiring configurations to ensure accurate signal transmission. Its design also includes protective measures to guard against physical damage and environmental factors 3.

Benefits

The advantages of the 3093363 Electronic Control Module Wiring Harness include improved engine performance through precise control of engine functions, enhanced fuel efficiency by optimizing combustion processes, and increased reliability due to its durable construction and robust design. This harness contributes to the overall efficiency and dependability of the truck’s engine management system.

Installation Process

Proper installation of the 3093363 Electronic Control Module Wiring Harness involves several steps. Begin by ensuring the truck’s electrical system is de-energized to prevent any risk of electrical shock. Carefully route the harness through the designated pathways to avoid sharp edges and moving parts. Secure the harness in place using the provided clamps and fasteners. Connect each wire to its corresponding terminal on the ECM and other components, ensuring a snug fit to prevent loose connections. Finally, perform a thorough inspection to confirm all connections are secure and the harness is properly installed.

Troubleshooting and Maintenance

To diagnose and resolve common issues with the 3093363 Electronic Control Module Wiring Harness, begin by inspecting the harness for any signs of physical damage, corrosion, or loose connections. Use a multimeter to test for continuity and ensure there are no breaks in the wiring. If an issue is detected, repair or replace the affected section of the harness as necessary. Regular maintenance practices include periodic inspection of the harness for wear and tear, cleaning connectors to prevent corrosion, and ensuring all connections remain secure.

Compatibility and Applications

The 3093363 Electronic Control Module Wiring Harness is designed to be compatible with a range of truck models and engine types. Its suitability for various operating conditions and environments makes it a versatile component in the commercial truck industry. Detailed compatibility information and specific applications will be provided separately to ensure accurate installation and optimal performance.

Safety Considerations

When working with the 3093363 Electronic Control Module Wiring Harness, it is important to observe several safety precautions. Ensure the truck’s electrical system is de-energized before beginning any work to avoid electrical shock. Handle the harness with care to prevent damage to the wires and connectors. Store the harness in a dry, cool place away from direct sunlight and extreme temperatures. Dispose of any damaged or obsolete harnesses according to local regulations to prevent environmental harm.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and innovative products. The company’s extensive product offerings include engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operators.

Cummins Electronic Control Module Wiring Harness 3093363 Compatibility

The Cummins Electronic Control Module (ECM) Wiring Harness part number 3093363 is a critical component designed to ensure seamless electrical connectivity between the ECM and various sensors, actuators, and other electronic components within the engine system. This wiring harness is engineered to provide reliable and efficient power and data transmission, essential for the optimal performance and diagnostics of the engine.

QST30 CM552 Engines

The 3093363 ECM Wiring Harness is specifically compatible with the QST30 CM552 engines. These engines are known for their robust design and are often utilized in heavy-duty applications where reliability and performance are paramount. The wiring harness is tailored to fit the unique electrical architecture of the QST30 CM552, ensuring that all necessary connections are made without interference or degradation of signal quality.

Grouping of Engines

The compatibility of the 3093363 ECM Wiring Harness extends to a range of Cummins engines, grouped based on their similar electrical systems and requirements. This grouping ensures that the wiring harness can be effectively used across multiple engine models, simplifying maintenance and repair processes. For instance, the harness is also suitable for other engines within the same series, providing a standardized solution for a variety of applications.

Importance of Proper Fitment

Proper fitment of the ECM Wiring Harness is crucial for maintaining the integrity of the engine’s electronic control system. Any mismatch or improper installation can lead to communication errors, reduced performance, and potential engine malfunctions. Therefore, it is essential to use the correct wiring harness for the specific engine model to ensure compatibility and reliability.

Role of Part 3093363 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3093363, serves as the vital connective tissue within an engine system, facilitating seamless communication and power distribution between the ECM and various engine components. This harness is engineered to ensure that the ECM can effectively monitor and control engine operations, enhancing overall performance and efficiency.

Integration with Engine Control Module (ECM)

At the heart of the engine system, the ECM relies on the wiring harness to transmit data and electrical signals to and from the engine’s sensors and actuators. The harness connects the ECM to critical components such as the fuel injectors, ignition coils, and oxygen sensors. This allows the ECM to make real-time adjustments to fuel delivery, ignition timing, and emissions control, optimizing engine performance under varying conditions.

Connection to Engine Components

The ECM Wiring Harness extends its reach to numerous engine components, ensuring each part operates in harmony. Key connections include:

- Fuel Injectors: The harness delivers control signals from the ECM to the fuel injectors, allowing precise fuel delivery based on engine load and operating conditions.

- Ignition Coils: It provides the necessary power and control signals to the ignition coils, ensuring timely and efficient spark generation for combustion.

- Oxygen Sensors: The harness facilitates the transmission of data from oxygen sensors to the ECM, enabling the system to maintain the ideal air-fuel ratio.

- Throttle Position Sensor (TPS): It connects the TPS to the ECM, allowing the system to adjust fuel and ignition timing based on throttle position.

- Mass Air Flow (MAF) Sensor: The harness ensures the MAF sensor data is accurately conveyed to the ECM, aiding in the calculation of the correct air-fuel mixture.

- Camshaft and Crankshaft Position Sensors: These sensors rely on the wiring harness to send rotational position data to the ECM, crucial for timing fuel injection and ignition events.

Enhancing System Reliability

By providing a robust and organized pathway for electrical signals and data, the ECM Wiring Harness enhances the reliability and durability of the engine system. It reduces the risk of electrical interference and ensures that all components receive the correct signals, leading to consistent engine performance and reduced wear on engine parts.

Conclusion

In summary, the ECM Wiring Harness (part 3093363) is integral to the efficient operation of modern engine systems. Its role in connecting the ECM to various engine components ensures that the engine operates smoothly, efficiently, and reliably under a wide range of conditions.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Majewski, Addy, and Jaskelainen, Hannu. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.