This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

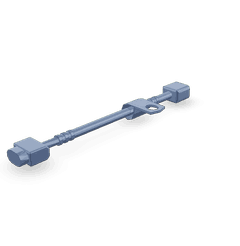

The Electronic Control Module Wiring Harness (Part #3099293) by Cummins is a vital component in the operation of heavy-duty trucks. This wiring harness is integral to the electronic control system of the vehicle, ensuring seamless communication and power distribution between the Electronic Control Module (ECM) and various truck components. Manufactured by Cummins, a reputable name in the automotive industry, this wiring harness is designed to enhance the performance and reliability of heavy-duty trucks 3.

Basic Concepts

The Electronic Control Module (ECM) is the brain of the truck’s electronic system, responsible for monitoring and controlling various engine functions and other critical systems. The wiring harness plays a role in the ECM system by facilitating communication and power distribution between the ECM and other components. It ensures that signals and power are transmitted efficiently, allowing the ECM to perform its functions accurately and reliably 2.

Purpose of the Electronic Control Module Wiring Harness

The Electronic Control Module Wiring Harness is designed to enable the ECM to monitor and control engine functions, transmission operations, and other critical systems within the truck. By providing a reliable pathway for electrical signals and power, it ensures that the ECM can effectively manage the truck’s performance, fuel efficiency, and emissions. This wiring harness is crucial for the overall operation and efficiency of the vehicle 1.

Key Features

The Electronic Control Module Wiring Harness is characterized by its robust design and high-quality materials. It is constructed to withstand the harsh conditions typically encountered in heavy-duty truck environments. The harness features durable connectors and cables, ensuring reliable performance over time. Additionally, it is designed to be compatible with a wide range of truck models, providing versatility and ease of use 3.

Benefits

The advantages provided by the Electronic Control Module Wiring Harness include improved engine performance, enhanced diagnostic capabilities, and increased reliability of the truck’s electronic systems. By ensuring efficient communication between the ECM and other components, it helps maintain optimal engine operation and fuel efficiency. Furthermore, its robust design contributes to the longevity and reliability of the truck’s electronic systems 1.

Installation Considerations

When installing the Electronic Control Module Wiring Harness, it is important to follow guidelines and best practices to ensure optimal performance. Compatibility with various truck models should be verified prior to installation. Proper installation involves securing the harness in place, ensuring all connections are tight and secure, and verifying that there are no obstructions or potential points of failure. Attention to detail during installation will help maintain the integrity and performance of the wiring harness 3.

Troubleshooting and Maintenance

Common issues that may arise with the Electronic Control Module Wiring Harness include loose connections, damaged cables, and faulty connectors. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Maintenance tips include checking for signs of wear or damage, ensuring all connections are secure, and protecting the harness from physical damage and environmental factors. Proactive maintenance will help prolong the lifespan of the wiring harness and ensure consistent performance 2.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality components and commitment to innovation. With a history of producing reliable and efficient parts for heavy-duty trucks, Cummins has built a reputation for excellence. The company’s dedication to quality and performance is evident in its products, including the Electronic Control Module Wiring Harness 3.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 3099293, is a critical component for the proper functioning of several Cummins engines. This wiring harness is designed to facilitate communication between the ECM and various sensors and actuators within the engine system.

ISM CM570 and ISM CM570/870

For the ISM CM570 and ISM CM570/870 engines, the ECM Wiring Harness ensures seamless data transfer and control. These engines, known for their robust performance, rely on this harness to maintain optimal operational parameters. The harness connects the ECM to the engine’s sensors and actuators, enabling precise control over fuel injection, exhaust gas recirculation, and other critical functions.

ISX CM570

The ISX CM570 engine also benefits from the ECM Wiring Harness. This engine is designed for heavy-duty applications, and the wiring harness plays a pivotal role in ensuring that the ECM can accurately monitor and control engine performance. The harness is engineered to withstand the rigors of demanding environments, providing reliable connectivity and data integrity.

QSM11 CM570

Similarly, the QSM11 CM570 engine utilizes the ECM Wiring Harness to maintain its high standards of performance and efficiency. This engine is often used in industrial applications, and the wiring harness is a key component in ensuring that the ECM can effectively manage engine operations. The harness is designed to handle the specific electrical demands of this engine, ensuring that all systems operate in harmony.

Each of these engines, despite their differences, relies on the ECM Wiring Harness to ensure that the ECM can effectively communicate with the engine’s various components. This harness is a critical part of the engine’s electrical system, ensuring that the ECM can accurately control and monitor engine performance 3.

Role of Part 3099293 Electronic Control Module Wiring Harness in Engine Systems

The Part 3099293 Electronic Control Module (ECM) Wiring Harness is integral to the operation of various engine systems, ensuring seamless communication and power distribution between the ECM and other components. Here’s how it interfaces with the provided components:

Integration with 24V Sentinel Install Kit and Sentinel Valve Kit

The ECM Wiring Harness facilitates the connection between the 24V Sentinel Install Kit and the ECM. This ensures that the Sentinel Valve Kit receives the necessary signals and power to regulate oil flow and pressure, maintaining optimal engine performance and protection.

Connection to Oil Replenishing Wiring and Components

For systems involving oil replenishing, such as the Centinel Make-Up QSX Kit and ISM Burn-Only Val/Mtg Kit, the ECM Wiring Harness provides the essential electrical connections. It allows the ECM to monitor and control the oil replenishing process, ensuring that the engine maintains the correct oil levels for efficient operation.

Support for ISM Centinel Repair and Valve & Mounting Kits

In the context of the ISM Centinel Repair Kit and ISM Valve & Mounting Kit, the ECM Wiring Harness plays a key role in repairing and maintaining the integrity of the oil control system. It ensures that the repaired or new components function correctly by providing the required electrical connections and signals from the ECM.

Functionality with ISX Burn-Only Val/Mtg and Oil Control Valve System

For the ISX Burn-Only Val/Mtg and the broader Oil Control Valve System, the ECM Wiring Harness is responsible for transmitting control signals and feedback data. This allows the ECM to adjust valve operations in real-time, optimizing fuel efficiency and reducing emissions.

Comprehensive Role in Oil Replenishing Systems

In oil replenishing systems, the ECM Wiring Harness ensures that all components, including those specific to oil replenishing, operate in unison. It provides the necessary electrical pathways for sensors and actuators, allowing the ECM to make precise adjustments to oil flow and pressure, thereby enhancing engine longevity and performance 3.

Conclusion

The Electronic Control Module Wiring Harness (Part #3099293) by Cummins is a critical component for the efficient and reliable operation of heavy-duty trucks. Its robust design, compatibility with various truck models, and integral role in the ECM system make it essential for maintaining optimal engine performance, fuel efficiency, and emissions control. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part.

-

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ ↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.