This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

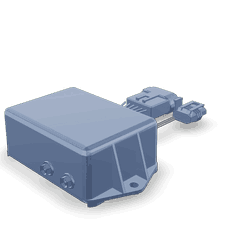

The Cummins 3160623 Electronic Control Module (ECM) is a sophisticated component designed for use in commercial trucks. It serves as the central processing unit for the truck’s engine management system, ensuring efficient and reliable operation. The ECM is integral to the overall performance of the vehicle, contributing to engine management, emissions control, and the integration of various vehicle systems.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages and controls various functions within a vehicle. It processes data from numerous sensors and actuators, making real-time adjustments to optimize performance. The ECM is part of the vehicle’s management system, which includes engine control, transmission management, and other subsystems. It ensures that all components work harmoniously to achieve the desired performance and efficiency 1.

Purpose and Role of the 3160623 ECM in Truck Operation

The Cummins 3160623 ECM is responsible for several key functions within a truck’s system. It manages engine operations by controlling fuel injection, ignition timing, and other critical parameters. The ECM also plays a role in emissions control, ensuring that the truck meets regulatory standards. Additionally, it integrates with other vehicle systems, such as the transmission and braking system, to provide a cohesive driving experience. The ECM’s ability to communicate with these systems allows for optimized performance and efficiency 2.

Key Features of the 3160623 ECM

The Cummins 3160623 ECM boasts several primary features that enhance its functionality. It has robust processing capabilities, allowing it to handle complex calculations and data processing in real-time. The ECM also offers substantial memory storage for diagnostic data and software updates. Its diagnostic functions enable it to identify and report issues, facilitating timely maintenance. Furthermore, the ECM provides various connectivity options, allowing it to interface with other systems and diagnostic tools.

Benefits of Using the 3160623 ECM

Incorporating the Cummins 3160623 ECM into truck systems offers several advantages. It contributes to improved fuel efficiency by optimizing engine operations. The ECM enhances overall performance through precise control of engine parameters. Additionally, it ensures better compliance with emissions regulations, reducing the environmental impact of commercial trucks. The ECM’s diagnostic capabilities also aid in maintaining the vehicle, leading to reduced downtime and increased reliability.

Troubleshooting and Maintenance Suggestions

Common issues with the Cummins 3160623 ECM may include software glitches, sensor malfunctions, or connectivity problems. Diagnostic procedures involve using specialized tools to access the ECM’s data and identify issues. Regular maintenance practices, such as software updates and sensor checks, can help ensure optimal performance and longevity. It is also beneficial to follow manufacturer guidelines for ECM care and maintenance.

Integration with Other Systems

The Cummins 3160623 ECM interacts with various truck systems to provide a seamless driving experience. It communicates with the transmission to optimize gear changes, enhancing fuel efficiency and performance. The ECM also integrates with the braking system, ensuring smooth and safe operation. Additionally, it works with driver assistance technologies, such as adaptive cruise control and collision avoidance systems, to improve safety and convenience.

Software and Firmware Updates

Keeping the ECM’s software and firmware up to date is important for maintaining optimal performance. Updates can introduce new features, improve efficiency, and address any identified issues. The procedure for updates typically involves connecting the ECM to a diagnostic tool and following the manufacturer’s instructions. Regular updates ensure that the ECM continues to operate at peak efficiency and remains compliant with current regulations.

Environmental and Operational Considerations

The Cummins 3160623 ECM is designed to operate under various environmental conditions, ensuring reliable performance in diverse settings. It plays a role in maintaining truck reliability and safety by adapting to changing conditions and optimizing engine performance. The ECM’s robust design and advanced features contribute to its ability to handle the demands of commercial truck operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, catering to various applications and industries. Cummins’ commitment to innovation and quality has solidified its position as a leader in the commercial truck market.

Role of Part 3160623 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM) part 3160623 is integral to the operation of various engine systems, particularly when paired with hardware such as 12V and 24V valve/electric kits.

Integration with 12V Valve/Electric Kit

When the ECM part 3160623 is interfaced with a 12V valve/electric kit, it assumes a pivotal role in regulating the valve operations. The ECM processes input data from sensors monitoring engine parameters such as temperature, pressure, and airflow. Based on this data, it sends precise signals to the 12V electric kit to adjust valve timing and duration. This ensures optimal fuel efficiency, reduces emissions, and enhances overall engine performance. The ECM’s capability to fine-tune valve operations in real-time allows for adaptive engine management, catering to varying load conditions and driving scenarios.

Coordination with 24V Valve/Electric Kit

In systems utilizing a 24V valve/electric kit, the ECM part 3160623 operates similarly but with increased voltage handling capabilities. The higher voltage system allows for more robust and rapid adjustments to valve operations. The ECM receives complex data inputs and translates them into commands that the 24V electric kit executes with greater precision and speed. This results in improved engine responsiveness, particularly in high-performance or heavy-duty applications where quick and accurate valve adjustments are essential. The ECM’s advanced algorithms ensure that the 24V system operates within safe parameters, preventing mechanical stress and prolonging component lifespan.

Enhanced Engine Management

In both 12V and 24V systems, the ECM part 3160623 facilitates comprehensive engine management by continuously monitoring and adjusting various parameters. It communicates with other engine components such as the fuel injectors, ignition system, and exhaust gas recirculation (EGR) system to maintain optimal engine operation. The ECM’s role in these interactions ensures that the engine operates efficiently under a wide range of conditions, from idle to full throttle, and in varying environmental conditions.

Adaptive Learning and Diagnostics

One of the standout features of the ECM part 3160623 is its adaptive learning capability. Over time, the ECM learns from the engine’s performance data and adjusts its control strategies to improve efficiency and performance. Additionally, the ECM is equipped with diagnostic capabilities that allow it to detect and report malfunctions in the valve/electric kits or other connected components. This proactive approach to maintenance helps in preventing catastrophic failures and ensures the engine remains in peak condition.

Conclusion

In summary, the ECM part 3160623 is a sophisticated component that enhances the functionality of both 12V and 24V valve/electric kits. Its role in real-time data processing, precise control of valve operations, and adaptive learning makes it an indispensable part of modern engine systems. The ECM ensures that the engine operates efficiently, reliably, and within specified performance parameters, contributing to both driver satisfaction and mechanical longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.