This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

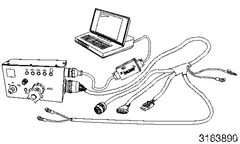

The Cummins 3163895 Electrical Cable is a specialized component designed for use in commercial truck operations. This cable plays a significant role in ensuring the reliable and efficient functioning of the truck’s electrical system. Its design and construction are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall performance and safety of the vehicle 1.

Basic Concepts of Electrical Cables

Electrical cables are conductors that transmit electric power or signals from one point to another. In vehicle electrical systems, these cables connect various components, allowing for the distribution of power and communication between systems. They are integral for the operation of lights, sensors, control units, and other electrical devices within the vehicle 2.

Purpose of the Cummins 3163895 Electrical Cable

This Cummins part is specifically designed to facilitate the transmission of electrical power within a truck’s electrical system. It connects critical components, ensuring that power is efficiently distributed to support the operation of the vehicle. This cable is integral to maintaining the functionality of the truck’s electrical systems, including lighting, engine controls, and diagnostic systems 3.

Key Features

The 3163895 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and environmental factors. The cable’s design includes protective coatings and insulation to safeguard against electrical interference and physical damage. Additionally, it is engineered to withstand the vibrations and temperature fluctuations common in heavy-duty truck operations 4.

Benefits

The use of this part offers several advantages. It provides improved reliability by ensuring consistent power delivery to critical systems. The cable’s durable construction contributes to the efficiency of the electrical system, reducing the likelihood of failures. Moreover, its design enhances safety by minimizing the risk of electrical shorts and other hazards associated with substandard cables 5.

Installation Considerations

When installing the 3163895, it is important to follow guidelines and best practices to ensure proper setup. This includes selecting the correct routing paths to avoid sharp edges and excessive bending, which could compromise the cable’s integrity. It is also crucial to secure the cable adequately to prevent movement that could lead to wear or damage over time 6.

Troubleshooting Common Issues

Common problems with electrical cables can include fraying, corrosion, and poor connections. For this part, addressing these issues involves inspecting the cable regularly for signs of wear or damage. Solutions may include repairing or replacing damaged sections, ensuring connections are secure, and protecting the cable from environmental factors that could lead to deterioration 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 3163895, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the cable and its connections can prevent buildup that might interfere with electrical conductivity. Additionally, ensuring that the cable is properly secured and protected can help maintain its condition over time 8.

Safety Precautions

When working with electrical cables, including the 3163895, it is vital to observe important safety measures. This involves ensuring that the power is off before beginning any work to prevent electrical shocks. Using appropriate tools and personal protective equipment can further enhance safety. It is also crucial to follow manufacturer guidelines and industry standards to prevent accidents and ensure personal safety 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its wide range of high-quality components, including the 3163895 Electrical Cable, which is designed to meet the rigorous demands of commercial truck operations 10.

Conclusion

The Cummins 3163895 Electrical Cable is a critical component in the electrical system of commercial trucks, designed to ensure reliable and efficient operation. Its robust construction, key features, and benefits make it a valuable asset for heavy-duty applications. Proper installation, maintenance, and adherence to safety precautions are essential to maximize its performance and longevity.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩ -

Cummins Inc. QSX15 CM2350 X106, Service Manual (4332712).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.