3164112

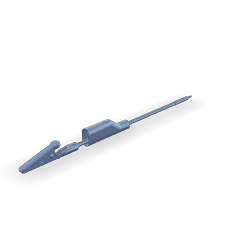

Electrical Test Lead

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3164112 Electrical Test Lead by Cummins is a specialized tool designed for the maintenance and diagnostics of commercial trucks. This part plays a crucial role in facilitating accurate electrical testing, which is vital for ensuring the optimal performance and reliability of truck electrical systems. Cummins, a renowned manufacturer in the commercial truck industry, produces this test lead, leveraging its expertise in diesel engines and related technologies 1.

Basic Concepts of Electrical Test Leads

Electrical test leads are tools used to connect diagnostic equipment to a vehicle’s electrical system. They function by providing a pathway for electrical signals, allowing technicians to measure voltage, current, and resistance within various components. Accurate electrical testing is essential for identifying issues within the truck’s electrical system, ensuring that all components operate within specified parameters, and preventing potential failures that could lead to downtime or safety hazards 2.

Purpose and Functionality of the 3164112 Electrical Test Lead

This Cummins part is designed specifically for use in truck diagnostics. It connects to various electrical systems and components within a truck, enabling technicians to perform tests and measurements accurately. This test lead facilitates the diagnosis of electrical issues by providing a reliable connection between diagnostic tools and the truck’s electrical system, ensuring that readings are precise and trustworthy.

Key Features

The 3164112 boasts several key features that enhance its functionality and ease of use. Its design is robust, ensuring durability in the demanding environment of truck diagnostics. The build quality is high, with materials chosen for their resilience and longevity. Connectivity options are versatile, allowing for seamless integration with a range of diagnostic equipment. Additionally, unique attributes such as ergonomic design and color-coded connectors contribute to its ease of use, making it a valuable tool for technicians 3.

Benefits of Using the 3164112 Electrical Test Lead

Using this part offers several advantages for truck diagnostics. It provides improved accuracy in readings, which is crucial for diagnosing electrical issues effectively. The ease of use, thanks to its design and connectivity options, allows technicians to perform tests efficiently. Its durability ensures that it can withstand the rigors of frequent use, contributing to efficient maintenance practices by reducing the need for frequent replacements.

Troubleshooting and Maintenance

Common issues with electrical test leads may include connectivity problems or damage to the leads themselves. Troubleshooting these issues involves checking connections for secure fitment and inspecting the leads for any signs of wear or damage. Maintaining the 3164112 involves proper storage in a dry, cool place to prevent corrosion, handling with care to avoid bending or twisting the leads, and cleaning with appropriate materials to remove any contaminants that could affect performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a leader in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. Its expertise in diesel engines and related technologies underscores the reliability and performance of its products, including the 3164112 Electrical Test Lead.

Role of Part 3164112 Electrical Test Lead in Engine Systems

In the intricate web of an engine system, the Electrical Test Lead (Part 3164112) serves as an essential tool for diagnosing and ensuring the proper functionality of various electrical components. When integrated with a Wiring Harness Repair Kit, this test lead becomes indispensable for maintaining the electrical integrity of the engine.

Diagnostic and Maintenance Applications

-

Wiring Harness Inspection: The Electrical Test Lead is employed to check the continuity and integrity of wires within the Wiring Harness Repair Kit. By connecting the test lead to specific points in the harness, technicians can identify breaks, shorts, or other faults that may impede the electrical flow.

-

Sensor Verification: Many engine systems rely on a network of sensors to monitor parameters such as temperature, pressure, and airflow. The test lead allows engineers to verify the output signals from these sensors, ensuring they are within the expected range and providing accurate data to the engine control unit (ECU).

-

Component Testing: Electrical components like ignition coils, fuel injectors, and solenoids can be tested using the Electrical Test Lead. By applying voltage or ground through the lead, technicians can confirm whether these components are receiving the correct electrical signals and functioning as intended.

-

Grounding Checks: Proper grounding is vital for the reliable operation of engine systems. The test lead can be used to check the resistance between various ground points and the engine block, helping to identify poor connections or corrosion that could lead to electrical issues.

-

Circuit Analysis: In complex engine systems, understanding the flow of electricity through different circuits is key. The Electrical Test Lead aids in mapping out these circuits, allowing for a thorough analysis of how electrical signals travel from the ECU to the various actuators and sensors.

Integration with Repair Kits

When combined with a Wiring Harness Repair Kit, the Electrical Test Lead enhances the repair process by providing real-time feedback on the effectiveness of repairs. This synergy ensures that any spliced or replaced sections of the wiring harness are functioning correctly, thereby maintaining the overall electrical health of the engine system.

Conclusion

In summary, the Electrical Test Lead (Part 3164112) is a versatile tool that plays a significant role in the diagnosis, maintenance, and repair of engine systems, particularly when used in conjunction with a Wiring Harness Repair Kit. Its ability to provide precise electrical measurements and insights makes it an invaluable asset for any engineer or mechanic working on engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.