3164113

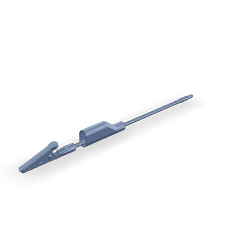

Electrical Test Lead

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3164113 Electrical Test Lead is a specialized tool designed for the maintenance and diagnostics of commercial trucks. It serves as a vital component in ensuring the electrical systems of trucks operate efficiently and reliably. This test lead facilitates the examination and testing of various electrical circuits and components, contributing to the overall health and performance of the vehicle.

Basic Concepts of Electrical Test Leads

Electrical test leads are tools used to connect diagnostic equipment to the electrical systems of vehicles. They function by providing a secure and reliable pathway for electrical signals, allowing technicians to measure voltage, current, and resistance within the vehicle’s electrical circuits. These leads are fundamental in automotive diagnostics, enabling the identification of faults and the assessment of the electrical system’s condition 1.

Purpose of the Cummins 3164113 Electrical Test Lead

The Cummins 3164113 Electrical Test Lead plays a role in the operation and diagnostics of trucks by allowing technicians to test electrical circuits and components. It is used to connect diagnostic tools to the truck’s electrical system, facilitating the measurement of electrical parameters and the detection of issues within the system. This test lead is instrumental in ensuring that the electrical components of a truck are functioning correctly, which is crucial for the vehicle’s overall performance and safety 2.

Key Features

The Cummins 3164113 Electrical Test Lead is characterized by its robust design and high-quality materials, which enhance its durability and reliability. It features a sturdy construction that can withstand the rigors of commercial truck environments. The materials used in its manufacture are selected for their ability to conduct electricity efficiently while resisting wear and corrosion. Additionally, the test lead may include unique characteristics such as color-coded connectors for easy identification and use, and flexible cables that allow for easy maneuvering in tight spaces 3.

Benefits of Using the Cummins 3164113 Electrical Test Lead

Utilizing the Cummins 3164113 Electrical Test Lead offers several advantages. It provides improved accuracy in diagnostics, ensuring that measurements are precise and reliable. The ease of use of this test lead allows technicians to quickly and efficiently connect it to diagnostic equipment and the truck’s electrical system. Furthermore, its durability ensures that it can withstand repeated use without degradation, making it a cost-effective tool for truck maintenance 4.

Applications in Truck Maintenance

The Cummins 3164113 Electrical Test Lead is employed in various scenarios within truck maintenance. It is used during routine maintenance checks to verify the condition of electrical circuits and components. In troubleshooting electrical issues, this test lead helps identify faults by allowing technicians to measure electrical parameters and compare them to expected values. It is also utilized in performing diagnostic tests to assess the overall health of the truck’s electrical system.

Suggestions on Troubleshooting and Maintenance

To troubleshoot common issues using the Cummins 3164113 Electrical Test Lead, technicians should follow a systematic approach, starting with visual inspections of the electrical system and then using the test lead to measure electrical parameters. Maintenance tips for ensuring the longevity and optimal performance of this test lead include keeping it clean and free from debris, storing it in a dry place to prevent corrosion, and inspecting it regularly for signs of wear or damage.

Safety Considerations

When using the Cummins 3164113 Electrical Test Lead, it is important to follow safety guidelines and precautions to avoid electrical hazards and ensure personal safety. Technicians should ensure that the truck’s engine is off and the electrical system is de-energized before connecting the test lead. Protective equipment, such as insulated gloves and safety glasses, should be worn to protect against electrical shocks and flying debris. Additionally, the work area should be well-lit and free from hazards to prevent accidents.

Integration with Diagnostic Tools

The Cummins 3164113 Electrical Test Lead is designed to integrate seamlessly with other diagnostic tools and equipment commonly used in truck maintenance. It provides a reliable connection between the diagnostic equipment and the truck’s electrical system, allowing for accurate measurements and diagnostics. This compatibility ensures that technicians can use a variety of diagnostic tools with the test lead, enhancing their ability to diagnose and resolve electrical issues.

User Experiences and Case Studies

Real-world examples and case studies illustrate the effectiveness of the Cummins 3164113 Electrical Test Lead in diagnosing and resolving electrical issues in commercial trucks. Technicians have reported successful identification and repair of faults in electrical circuits and components using this test lead. These experiences highlight the tool’s reliability, accuracy, and ease of use in practical applications.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Role of Electrical Test Lead in Engine Systems

The Electrical Test Lead (Part 3164113) is an essential tool for diagnosing and maintaining various engine systems. When integrated with components such as the Wiring Harness Repair Kit, it facilitates thorough inspections and repairs.

Application in Engine Systems

-

Wiring Harness Repair: The Electrical Test Lead is used to identify faults within the wiring harness. By connecting to specific points in the harness, it allows engineers and mechanics to measure voltage, continuity, and resistance. This helps in pinpointing damaged sections that need repair or replacement, ensuring the integrity of the electrical system.

-

Sensor Diagnostics: In engine systems equipped with multiple sensors (e.g., oxygen sensors, temperature sensors), the test lead assists in verifying the functionality of these components. It enables professionals to check signal outputs and ensure sensors are providing accurate data to the engine control unit (ECU).

-

Ignition System Testing: For ignition systems, the Electrical Test Lead is employed to assess the performance of ignition coils, spark plugs, and related wiring. This ensures that the ignition system is delivering the correct voltage at the right time, contributing to efficient combustion.

-

Fuel Injection System: In fuel-injected engines, the test lead is used to evaluate the operation of fuel injectors. By measuring the electrical signals sent to the injectors, professionals can confirm that fuel delivery is precise and consistent, which is vital for engine performance and fuel efficiency.

-

ECU Communication: The Electrical Test Lead aids in diagnosing issues related to the Engine Control Unit (ECU). It helps in checking communication lines and data signals between the ECU and various engine components, ensuring that all systems are operating in harmony.

-

Ground Connections: Ensuring proper ground connections is fundamental for the electrical system’s reliability. The test lead is utilized to verify the integrity of ground wires and connections, preventing issues such as electrical noise, intermittent faults, and system failures.

By employing the Electrical Test Lead in these applications, engineers and mechanics can maintain and troubleshoot engine systems with greater accuracy and efficiency.

Conclusion

The Cummins 3164113 Electrical Test Lead is a critical tool for the maintenance and diagnostics of commercial trucks. Its robust design, high-quality materials, and ease of use make it an invaluable asset for technicians. By facilitating accurate measurements and diagnostics, this test lead contributes to the overall health and performance of the vehicle’s electrical systems. Its integration with other diagnostic tools enhances the ability to diagnose and resolve electrical issues, ensuring the reliability and safety of commercial trucks.

-

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Klyde, Michael, and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.