3164292

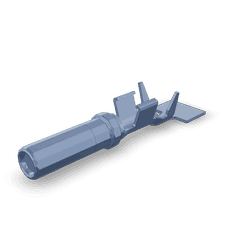

terminal.elc Repair

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Terminal Electrical Repair 3164292 by Cummins is a specialized component designed to address electrical connection issues in commercial trucks. Its purpose is to ensure reliable and efficient electrical connections, which are vital for the proper operation and maintenance of commercial vehicles. This repair component plays a role in maintaining the electrical integrity of truck systems, thereby contributing to overall vehicle performance and reliability.

Basic Concepts of Terminal Electrical Repair

Terminal electrical repairs involve the restoration and maintenance of electrical connections at terminals, which are points where electrical circuits connect. Common issues include corrosion, wear, and poor connections, which can lead to electrical failures or inefficiencies. Maintaining these connections is important for ensuring the consistent performance of electrical systems in commercial trucks. Proper terminal maintenance helps prevent downtime, enhances safety, and ensures that all electrical components function as intended.

Purpose of Terminal Electrical Repair 3164292

The Terminal Electrical Repair 3164292 is designed to play a role in the electrical system by providing a reliable connection solution. It functions by replacing or repairing damaged terminals, ensuring that electrical circuits remain intact and operate efficiently. This component contributes to the overall performance and reliability of the truck by maintaining stable electrical connections, which are necessary for the operation of various truck systems, including lighting, instrumentation, and engine controls.

Key Features

The Terminal Electrical Repair 3164292 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-lasting use. The design includes elements that facilitate easy installation and secure connections. Additionally, it may feature unique characteristics such as enhanced conductivity materials or specialized coatings that further improve its functionality and resilience in demanding environments.

Benefits

Using the Terminal Electrical Repair 3164292 offers several benefits. It provides improved electrical conductivity, ensuring that connections are reliable and efficient. The enhanced durability of the component means it can withstand the rigors of commercial truck operations, reducing the frequency of repairs. Additionally, the use of this repair component can lead to potential cost savings through extended component life and reduced maintenance needs, making it a valuable asset for fleet managers and technicians.

Installation Process

Installing the Terminal Electrical Repair 3164292 involves several steps to ensure a secure and effective repair. The process begins with gathering the necessary tools, such as wire strippers, crimping tools, and a multimeter. Preparation steps include cleaning the terminal area to remove any corrosion or debris. The installation involves stripping the wire, inserting it into the terminal, and crimping it securely. Best practices include verifying the connection with a multimeter to ensure proper conductivity and inspecting the repair for any signs of damage or loose connections.

Troubleshooting Common Issues

Common issues with terminal electrical connections in trucks include corrosion, loose connections, and damaged terminals. The Terminal Electrical Repair 3164292 can address these problems by providing a robust and reliable connection solution. Troubleshooting involves identifying the specific issue, whether it is a corroded terminal or a loose wire, and applying the appropriate repair using the 3164292 component. This may involve cleaning the area, replacing damaged parts, and ensuring all connections are secure and conductive.

Maintenance Tips

Maintaining terminal electrical connections and the Terminal Electrical Repair 3164292 involves regular inspection practices. This includes checking for signs of corrosion, wear, or loose connections during routine maintenance checks. Cleaning procedures should be performed to remove any buildup that could affect conductivity. Knowing when to consider replacement or further repair is also important; if the terminal shows significant wear or if connections are consistently loose, it may be time for a replacement.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial vehicle industry, known for its wide range of products and strong reputation for quality and reliability. Founded in 1919, Cummins has a long history of innovation and excellence in engine and power generation technologies. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial fleets. The Terminal Electrical Repair 3164292 is part of Cummins’ commitment to providing high-quality, reliable components for the maintenance and operation of commercial trucks 1.

Cummins Terminal Electrical Repair Part 3164292 Compatibility

The Cummins Terminal Electrical Repair part number 3164292 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connections and performance. This part is particularly suited for use in the following engines:

- QSNT14

- CM876

- N102

These engines, while distinct in their specifications and applications, share common electrical systems that benefit from the robust design of the 3164292 terminal repair kit. The part’s compatibility with these engines underscores its versatility and effectiveness in maintaining the integrity of electrical connections, which is crucial for the overall performance and longevity of the engines 2.

Role of Part 3164292 Terminal Electrical Repair in Engine Systems

Part 3164292 Terminal Electrical Repair is an essential component in maintaining the integrity and functionality of various electrical systems within an engine. Its application spans across several key areas:

Accessories

In the realm of engine accessories, this terminal repair part ensures that electrical connections remain secure and efficient. Whether it’s powering auxiliary systems like fuel pumps, cooling fans, or lighting, the reliability of these connections is paramount. The terminal repair facilitates consistent power delivery, preventing intermittent failures that could lead to accessory malfunction.

Electrical Systems

At the heart of any engine’s operation lies its electrical system, which relies on a network of terminals to transmit power and signals. Part 3164292 plays a significant role in maintaining these connections, ensuring that sensors, actuators, and control modules receive the necessary electrical input to function correctly. This is particularly important in modern engines where electronic control units (ECUs) govern a wide array of operations.

Electrical Accessories

Electrical accessories, such as onboard diagnostics (OBD) systems, rely heavily on the integrity of their electrical connections. The terminal repair part ensures that these accessories can communicate effectively with the engine’s control systems, providing accurate data and diagnostics. This is vital for both the performance monitoring and troubleshooting of the engine.

Wiring Harness Repair Kit

When it comes to comprehensive repairs, the wiring harness repair kit often includes components like part 3164292. This terminal repair is used to restore damaged or corroded connections within the wiring harness. By doing so, it helps in maintaining the overall electrical health of the engine, ensuring that all components from the battery to the smallest sensor are connected reliably.

Conclusion

In summary, part 3164292 Terminal Electrical Repair is a fundamental component in the maintenance and repair of engine electrical systems. Its application across accessories, core electrical systems, electrical accessories, and wiring harness repair kits underscores its versatility and importance in ensuring the engine operates smoothly and efficiently 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.