This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

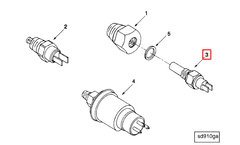

The Cummins 3281214 Transducer is a specialized component designed for use in heavy-duty truck systems. Its primary role is to convert physical parameters, such as pressure or temperature, into electrical signals that can be interpreted by the truck’s electronic control systems. This conversion allows for precise monitoring and control of various engine and vehicle functions, contributing to overall system efficiency and performance.

Basic Concepts of Transducers

A transducer is a device that converts one form of energy into another. In automotive applications, transducers are commonly used to translate physical measurements into electrical signals. These signals are then processed by the vehicle’s electronic control unit (ECU) to adjust engine parameters, monitor system health, and ensure optimal performance. Transducers play a vital role in modern automotive systems by providing real-time data that enables sophisticated control strategies 1.

Purpose of the Cummins 3281214 Transducer

The Cummins 3281214 Transducer is specifically designed to measure and report pressure within the truck’s systems. It integrates seamlessly with the truck’s electronic control systems, providing accurate and reliable data that is used to adjust engine performance, monitor system conditions, and ensure that the truck operates within safe parameters. By offering precise pressure readings, this transducer helps maintain engine efficiency, reduce emissions, and enhance overall vehicle performance.

Key Features

The Cummins 3281214 Transducer is engineered with several key features that enhance its functionality and reliability. Its design incorporates high-quality materials to ensure durability in the demanding environment of heavy-duty trucks. The transducer is equipped with advanced technological specifications, including high-resolution sensors and robust signal processing capabilities, to deliver accurate and consistent performance. Additionally, its compact design allows for easy integration into existing truck systems.

Benefits of Using the Cummins 3281214 Transducer

Incorporating the Cummins 3281214 Transducer into truck systems offers several advantages. It enhances system efficiency by providing precise pressure data that allows for fine-tuned engine control. This results in improved fuel economy and reduced emissions. The transducer’s reliability ensures consistent performance, minimizing the risk of system failures. Furthermore, its integration into the truck’s electronic systems contributes to overall performance improvements, making it a valuable component for heavy-duty applications.

Installation and Integration

Installing the Cummins 3281214 Transducer involves several steps to ensure proper integration into the truck’s systems. Initially, the transducer must be mounted in a location that allows for accurate pressure measurement. This typically involves securing it to a suitable point within the engine compartment. Once mounted, the transducer is connected to the truck’s electronic control unit using the appropriate wiring harness. Care must be taken to ensure all connections are secure and properly insulated to prevent electrical issues. Finally, the system should be tested to confirm that the transducer is functioning correctly and providing accurate data.

Troubleshooting and Maintenance

Common issues with the Cummins 3281214 Transducer may include inaccurate readings, signal interference, or physical damage. Diagnostic procedures involve checking the transducer’s connections, ensuring it is properly mounted, and verifying that the electrical signals are within expected parameters. Regular maintenance includes inspecting the transducer for signs of wear or damage, cleaning any debris that may affect its performance, and ensuring that all connections remain secure. Prompt attention to these issues helps maintain the transducer’s longevity and optimal performance.

Performance Monitoring

Monitoring the performance of the Cummins 3281214 Transducer is crucial for ensuring its continued accuracy and reliability. This can be achieved through the use of diagnostic tools that allow for real-time monitoring of pressure readings and signal integrity. Regular checks should be performed to verify that the transducer is operating within specified parameters. Additionally, keeping detailed records of performance data can help identify trends or potential issues before they become critical, ensuring the transducer remains an effective component of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established itself as a trusted name in the automotive industry, particularly in the production of heavy-duty truck components. The company’s commitment to innovation, quality, and customer satisfaction has made it a preferred choice for manufacturers and operators of heavy-duty vehicles. Cummins continues to play a significant role in advancing technology and performance in the automotive sector.

Cummins Transducer 3281214 Compatibility

The Cummins Transducer part number 3281214 is designed to integrate seamlessly with specific engine models, ensuring optimal performance and reliability. This transducer is a critical component in the engine’s electronic control system, responsible for converting mechanical or electrical signals into a form that can be processed by the engine control unit (ECU).

6B5.9 Engine

For the 6B5.9 engine, the transducer plays a pivotal role in the engine’s diagnostic and monitoring systems. It provides essential data to the ECU, which is crucial for maintaining engine efficiency and performance. The 6B5.9 engine benefits from this transducer’s precise signal conversion, enhancing overall engine responsiveness and reducing the likelihood of malfunctions.

6C8.3 Engine

Similarly, in the 6C8.3 engine, the transducer is integral to the engine’s operational integrity. It ensures that the ECU receives accurate and timely data, which is vital for the engine’s performance under various operating conditions. The 6C8.3 engine’s design leverages this transducer to maintain a balance between power output and fuel efficiency, contributing to its robust performance profile.

Grouping of Engines

Both the 6B5.9 and 6C8.3 engines share a common requirement for precise signal conversion, making the Cummins Transducer 3281214 an essential component for both. The compatibility of this transducer with these engines underscores its versatility and importance in modern engine systems. By ensuring that both engines receive accurate data from the transducer, Cummins maintains the high standards of performance and reliability that their customers expect.

Role of Part 3281214 Transducer in Engine Systems

The part 3281214 transducer is an essential component in the monitoring and regulation of engine systems. It operates by converting physical parameters such as pressure, temperature, and vibration into electrical signals that can be interpreted by the engine control unit (ECU).

Integration with Engine Monitoring Systems

When integrated into engine monitoring systems, the 3281214 transducer provides real-time data that allows for precise adjustments and optimizations. This data is vital for maintaining engine performance and efficiency. The transducer works in conjunction with sensors and actuators to ensure that the engine operates within specified parameters.

Interaction with the ECU

The electrical signals generated by the 3281214 transducer are sent to the ECU, where they are analyzed and used to make necessary adjustments. For instance, if the transducer detects a rise in engine temperature, the ECU can activate the cooling system to prevent overheating. Similarly, changes in pressure can trigger adjustments in fuel injection to optimize combustion.

Role in Diagnostic Systems

In diagnostic systems, the 3281214 transducer plays a significant role by providing continuous feedback on the engine’s condition. This allows for early detection of potential issues, enabling proactive maintenance and reducing the risk of unexpected failures. The data collected can also be used to perform thorough analyses, helping to identify patterns and trends that may indicate underlying problems.

Contribution to Performance Optimization

By providing accurate and timely data, the 3281214 transducer contributes to the overall optimization of engine performance. It enables the ECU to make fine-tuned adjustments that enhance efficiency, reduce emissions, and improve power output. This is particularly important in high-performance engines where even minor adjustments can have a significant impact.

Support for Advanced Engine Features

In engines equipped with advanced features such as variable valve timing or turbocharging, the 3281214 transducer is instrumental in ensuring these systems operate effectively. It provides the necessary data for the ECU to control these features, allowing for dynamic adjustments that enhance performance and efficiency under varying conditions.

Enhancement of Safety Systems

The transducer also plays a role in enhancing safety systems within the engine. By providing real-time data on critical parameters, it allows the ECU to implement safety protocols that protect the engine from damage. This includes activating fail-safe modes in response to abnormal conditions, thereby preventing catastrophic failures.

Conclusion

The Cummins 3281214 Transducer is a versatile component that enhances the functionality and reliability of engine systems through precise monitoring and data provision. Its integration into heavy-duty truck systems ensures optimal performance, efficiency, and safety, making it an indispensable part of modern automotive technology.

-

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.