This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3330511 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the performance of commercial trucks. This ECM is integral to the operation of these vehicles, ensuring efficient engine management, precise emissions control, and comprehensive diagnostic capabilities. Its role is significant in maintaining the overall functionality and reliability of the truck 2.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that plays a central role in the operation of modern vehicle systems. It functions by receiving input from various sensors throughout the vehicle, processing this data, and sending output signals to actuators to control different systems. The ECM is responsible for managing engine operations, regulating emissions, and providing diagnostic information, making it a cornerstone of vehicle automation and performance optimization 1.

Role of the 3330511 Electronic Control Module in Truck Operation

The Cummins 3330511 ECM is specifically engineered to perform a range of functions within a truck’s system. It manages engine operations by controlling fuel injection, ignition timing, and other critical parameters to ensure optimal performance. Additionally, it plays a role in emissions control by monitoring and adjusting engine parameters to meet regulatory standards. The ECM also offers diagnostic capabilities, allowing for the detection and logging of faults, which aids in maintenance and repair processes.

Key Features

The Cummins 3330511 ECM is equipped with several key features that enhance its functionality. It boasts significant processing power and memory capacity, enabling it to handle complex calculations and store large amounts of data. The ECM offers various connectivity options, allowing it to interface with other systems and devices. It also incorporates unique technological advancements that improve its performance and reliability.

Benefits of Using the 3330511 ECM

Utilizing the Cummins 3330511 ECM provides several advantages. It contributes to improved engine performance by optimizing fuel injection and ignition timing. The ECM enhances fuel efficiency through precise control of engine parameters. It also aids in reducing emissions by ensuring the engine operates within regulatory limits. Furthermore, the ECM increases the reliability of the truck by continuously monitoring and adjusting engine operations.

Integration with Other Systems

The Cummins 3330511 ECM is designed to interact seamlessly with other truck systems. It communicates with the transmission to ensure smooth gear changes, works with the braking system to enhance safety, and can interface with aftermarket devices for additional functionality. This integration allows for a cohesive and efficient operation of the truck’s various systems.

Diagnostic and Monitoring Capabilities

The Cummins 3330511 ECM offers comprehensive diagnostic and monitoring features. It provides real-time data logging, allowing for immediate access to engine performance metrics. The ECM can retrieve fault codes, which help in identifying and addressing issues promptly. It also offers performance analytics, enabling fleet managers to optimize truck operations and maintenance schedules.

Troubleshooting and Maintenance Suggestions

For troubleshooting common issues with the Cummins 3330511 ECM, it is advisable to consult the manufacturer’s guidelines and use diagnostic tools compatible with the ECM. Regular maintenance, including software updates and calibrations, is recommended to ensure optimal performance. Following the manufacturer’s maintenance schedule and guidelines can help prevent issues and extend the lifespan of the ECM.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry, Cummins is committed to innovation and quality in diesel engine technology. The company’s dedication to advancing engine performance and efficiency is evident in its products, including the Cummins 3330511 ECM 2.

Compatibility with Cummins Engines

The Cummins Electronic Control Module (ECM) part number 3330511 is a critical component for the operation of various Cummins engines. This ECM is designed to manage and control the engine’s performance, ensuring optimal efficiency and reliability.

QSK19 CM500 Engines

The ECM 3330511 is specifically engineered to interface seamlessly with the QSK19 CM500 engines. These engines are known for their robust performance and are widely used in various industrial applications. The ECM ensures precise control over the engine’s fuel injection, ignition timing, and other critical functions, enhancing overall engine performance and longevity.

Integration and Functionality

The integration of the ECM 3330511 with the QSK19 CM500 engines involves several key functionalities:

-

Fuel Injection Control: The ECM regulates the fuel injection process, ensuring that the engine receives the correct amount of fuel at the right time. This precision helps in maintaining optimal combustion efficiency and reducing emissions.

-

Ignition Timing: The ECM adjusts the ignition timing to match the engine’s operating conditions, which is crucial for maximizing power output and fuel efficiency.

-

Diagnostic Capabilities: The ECM is equipped with advanced diagnostic features that allow for real-time monitoring of engine performance. This capability helps in early detection of potential issues, preventing breakdowns and reducing maintenance costs.

-

Communication: The ECM communicates with other vehicle systems, such as the transmission and exhaust aftertreatment systems, to ensure coordinated operation and optimal performance.

Reliability and Performance

The ECM 3330511 is built to withstand the demanding conditions of industrial and heavy-duty applications. Its robust design ensures reliable performance, even in harsh environments. The ECM’s advanced algorithms and sensors provide precise control, contributing to the overall efficiency and durability of the QSK19 CM500 engines.

By integrating the ECM 3330511 with the QSK19 CM500 engines, users can expect enhanced engine performance, improved fuel efficiency, and reduced downtime. This compatibility is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Role of Part 3330511 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), identified by part number 3330511, is integral to the operation of several key components within engine systems. It acts as the central processing unit, receiving data from various sensors and sending commands to actuators to maintain optimal engine performance.

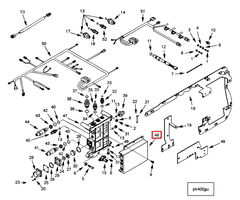

Integration with Electronic Fuel Control Valve

The ECM, part 3330511, continuously monitors inputs from the Electronic Fuel Control Valve. This valve regulates the amount of fuel entering the engine based on driving conditions. The ECM processes data such as engine load, throttle position, and air intake temperature to adjust the fuel delivery precisely. This ensures efficient combustion and reduces emissions.

Coordination with Electronic Service Calibration

During maintenance or after component replacements, the ECM requires recalibration to ensure all systems operate harmoniously. The Electronic Service Calibration process involves updating the ECM’s software to reflect any changes in the engine’s hardware or operating parameters. This calibration ensures that the ECM can accurately interpret sensor data and deliver the appropriate commands to the fuel control valve and other actuators.

Interaction with Engine Control Module

While the terms Engine Control Module (ECM) and Electronic Control Module are often used interchangeably, it’s important to note that part 3330511 specifically refers to a sophisticated ECM designed to handle complex engine management tasks. This module communicates with other ECMs within the engine system to coordinate functions such as ignition timing, fuel injection, and emissions control.

The ECM uses a network of sensors to gather real-time data on engine performance. It then processes this information to make split-second adjustments, ensuring the engine operates within specified parameters for performance, efficiency, and emissions compliance.

Conclusion

The Cummins 3330511 Electronic Control Module is a vital component in the operation and maintenance of commercial trucks. Its sophisticated design and advanced features ensure optimal engine performance, precise emissions control, and comprehensive diagnostic capabilities. By integrating seamlessly with other truck systems and offering robust diagnostic and monitoring features, this ECM enhances the overall functionality and reliability of the vehicle. Regular maintenance and adherence to manufacturer guidelines are essential to maximize the benefits and longevity of the Cummins 3330511 ECM.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.