This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3393102 Operations and Maintenance Manual Literature serves as a comprehensive guide for the maintenance and operation of commercial trucks equipped with Cummins engines. This manual is designed to provide detailed information and instructions to ensure the efficient and safe operation of these vehicles. Its significance lies in its ability to offer a structured approach to maintenance, thereby contributing to the longevity and performance of the trucks 2.

Basic Concepts of Operations and Maintenance Manual Literature

Operations and Maintenance Manual Literature encompasses detailed documentation that outlines the procedures and guidelines necessary for the upkeep and operation of machinery and vehicles. In the automotive industry, such literature is vital as it ensures that vehicles are maintained according to manufacturer specifications, which can lead to improved performance, safety, and longevity 3. This type of manual aids in the efficient operation and maintenance of commercial trucks by providing clear, actionable instructions and insights into the vehicle’s systems and components.

Purpose of the 3393102 Operations and Maintenance Manual Literature

The Cummins 3393102 manual plays a specific role in the operation and maintenance of trucks by offering detailed guidance on engine-related procedures. It assists engineers, mechanics, truck drivers, and fleet operators by providing them with the necessary information to perform maintenance tasks, troubleshoot issues, and understand the operational parameters of Cummins engines. This manual ensures that all stakeholders have access to the information needed to maintain the vehicle in optimal condition 4.

Key Features

The primary features of the 3393102 manual include a well-organized structure that allows for easy navigation. It contains a variety of content types such as text descriptions, diagrams, and tables that facilitate understanding complex procedures. Special sections within the manual, such as troubleshooting guides and maintenance schedules, are designed to be particularly useful for users. These features make the manual a valuable resource for anyone involved in the maintenance and operation of Cummins-powered trucks 1.

Benefits of Using the 3393102 Manual

Utilizing the 3393102 manual offers several advantages. It promotes improved maintenance practices by providing clear, step-by-step instructions. Enhanced safety is another benefit, as the manual outlines procedures that help prevent accidents and equipment failure. Additionally, the manual contributes to increased efficiency by ensuring that maintenance tasks are performed correctly and promptly. Potential cost savings for fleet operators are also a significant advantage, as proper maintenance can extend the lifespan of the vehicle and reduce the need for costly repairs 2.

Suggestions on Troubleshooting and Maintenance

The 3393102 manual provides practical advice and guidelines for troubleshooting common issues and performing routine maintenance tasks. These suggestions are designed to help maintain the truck’s performance and longevity by addressing problems before they escalate and ensuring that all components are in good working order. The manual’s troubleshooting section is particularly useful for identifying and resolving issues quickly and effectively 3.

Usage Guidelines

To effectively use the 3393102 manual, users should familiarize themselves with its structure and navigation. Understanding the technical jargon and applying the information in real-world scenarios are key to maximizing the manual’s benefits. Tips on how to interpret diagrams and tables, as well as how to follow procedural instructions, are provided to ensure that users can make the most of the manual’s content 4.

Integration with Other Maintenance Resources

The 3393102 manual can be used in conjunction with other maintenance resources and tools to optimize truck maintenance strategies. By integrating this manual with diagnostic software, training materials, and other documentation, users can create a comprehensive maintenance plan that addresses all aspects of truck upkeep. This holistic approach ensures that all maintenance tasks are performed efficiently and effectively 1.

Training and Certification

There are training programs and certification processes associated with the use of the 3393102 manual. These programs are designed to ensure that users are adequately prepared to apply the manual’s contents. Training may include workshops, online courses, and hands-on practice, while certification verifies that individuals have the knowledge and skills required to maintain Cummins engines according to the manual’s guidelines 2.

Feedback and Continuous Improvement

User feedback plays a role in improving the 3393102 manual. Cummins incorporates this feedback into future editions to ensure that the manual remains relevant and effective. By listening to the experiences and suggestions of users, Cummins can make necessary updates and enhancements that benefit the entire user community 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various industries. Cummins’ dedication to excellence and continuous improvement is reflected in its comprehensive maintenance and operations manuals, such as the 3393102 4.

Understanding the Role of Part 3393102 Operations and Maintenance Manual Literature in Engine Systems

Part 3393102 Operations and Maintenance Manual Literature is an essential resource for engineers and mechanics working with complex engine systems. This manual provides detailed instructions and guidelines on the operation and maintenance of various components, ensuring optimal performance and longevity of the engine.

Integration with Engine Components

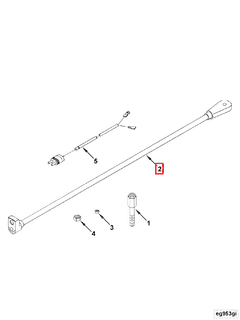

Harness

The manual offers comprehensive guidance on the installation, inspection, and maintenance of the engine harness. It details the correct procedures for connecting and securing the harness to ensure reliable electrical connections and prevent issues such as short circuits or power loss. Additionally, it provides troubleshooting tips for common harness-related problems, enabling technicians to quickly identify and resolve issues 1.

Alternator Wiring Harness

For the alternator wiring harness, the manual outlines the steps for proper installation and connection. It emphasizes the importance of correct wiring to ensure the alternator functions efficiently, providing a stable electrical supply to the engine and other components. The manual also includes maintenance schedules and inspection checklists to help prevent alternator failures and ensure consistent performance 2.

General Wiring

The manual covers general wiring practices applicable to various engine systems. It provides best practices for wiring installation, including routing, securing, and protecting wires from environmental factors such as heat, moisture, and vibration. Furthermore, it offers detailed diagrams and illustrations to aid in understanding complex wiring configurations and connections 3.

By following the guidelines in Part 3393102 Operations and Maintenance Manual Literature, engineers and mechanics can ensure that all wiring and harness components are installed and maintained correctly, contributing to the overall reliability and efficiency of the engine system 4.

Conclusion

The Cummins 3393102 Operations and Maintenance Manual Literature is a vital resource for the maintenance and operation of Cummins engines. It provides detailed guidance, enhances safety, increases efficiency, and offers potential cost savings. By integrating this manual with other maintenance resources and ensuring proper training and certification, users can maintain their engines to the highest standards, ensuring optimal performance and longevity.

-

Fundamentals of Automotive Technology Principles and Practice, Kirk T Van Gelder, Jones Bartlett Learning, 2018

↩ ↩ ↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014

↩ ↩ ↩ ↩ -

Modern Diesel Technology Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Delmar Cengage Learning, 2014

↩ ↩ ↩ ↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.