3408509

Electrical Connector Adapter

Cummins®

AVAILABLE

9 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3408509 Electrical Connector Adapter is a component designed by Cummins to facilitate the connection between various electrical components within commercial trucks. This adapter plays a role in ensuring the seamless operation of the truck’s electrical system by providing a reliable interface for signal and power transmission. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing components that enhance the performance and reliability of commercial vehicles 1.

Basic Concepts of Electrical Connector Adapters

An Electrical Connector Adapter serves as a bridge between different electrical components, allowing for the transfer of signals and power within a truck’s electrical system. Reliable electrical connections are fundamental in heavy-duty vehicles, as they ensure the proper functioning of critical systems and components. These adapters are designed to withstand the harsh conditions typical of commercial truck environments, including vibrations, temperature fluctuations, and exposure to moisture 2.

Purpose of the 3408509 Electrical Connector Adapter

The 3408509 Electrical Connector Adapter is specifically designed to connect various electrical components within a truck’s system, facilitating efficient signal transmission. It ensures that electrical signals are accurately conveyed between components, which is vital for the operation of systems such as engine management, lighting, and diagnostic systems. By providing a secure and reliable connection, this adapter contributes to the overall efficiency and reliability of the truck’s electrical network 3.

Key Features

The 3408509 Electrical Connector Adapter boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The adapter is engineered to provide a snug fit, minimizing the risk of disconnections due to vibrations. Additionally, it features protective coatings that safeguard against environmental factors, further contributing to its reliability 4.

Benefits

The use of the 3408509 Electrical Connector Adapter offers several benefits. It enhances electrical reliability by ensuring stable connections between components, which is crucial for the consistent operation of the truck’s systems. The adapter’s design also facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, by ensuring reliable connections and reducing the likelihood of electrical faults, it can lead to potential cost savings through decreased maintenance needs 5.

Installation Process

Installing the 3408509 Electrical Connector Adapter involves several steps to ensure a secure and effective connection. Begin by identifying the correct location for the adapter within the truck’s electrical system. Carefully align the adapter with the corresponding connectors, ensuring that all pins and contacts are properly aligned. Apply gentle pressure to seat the adapter fully, and use any provided locking mechanisms to secure it in place. It is important to follow manufacturer guidelines to avoid common pitfalls such as misalignment or insufficient seating, which could compromise the connection’s integrity 6.

Troubleshooting Common Issues

Common issues with Electrical Connector Adapters may include poor connections or signal interference. To address these problems, first, ensure that the adapter is correctly installed and securely seated. Inspect the contacts for signs of corrosion or damage, cleaning or replacing them as necessary. If signal interference is suspected, check for nearby sources of electromagnetic interference and consider shielding the adapter or relocating it to minimize the impact 7.

Maintenance Tips

To ensure the long-term performance of the 3408509 Electrical Connector Adapter, regular maintenance is recommended. Inspect the adapter and its connections at routine intervals for signs of wear, corrosion, or damage. Cleaning the contacts with an appropriate cleaner can help maintain a reliable connection. If significant wear or damage is observed, consider replacing the adapter to prevent potential electrical issues 8.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry. The company is widely recognized for its commitment to quality and innovation in producing automotive components. Cummins’ reputation is built on a foundation of delivering reliable, high-performance parts that meet the demanding requirements of commercial vehicles. Their dedication to advancing technology and improving product quality underscores their position as a leader in the industry 9.

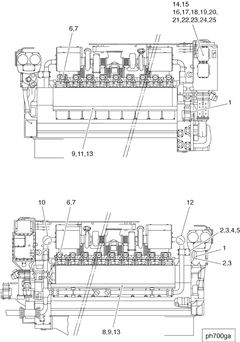

Electrical Connector Adapter 3408509 in Cummins Engines

The Electrical Connector Adapter 3408509, manufactured by Cummins, is a critical component in ensuring seamless electrical connectivity and compatibility across various Cummins engine models. This adapter is specifically designed to interface with the electrical systems of the QSK45 CM500, QSK60 CM500, and QSK60G engines, facilitating efficient power distribution and communication between different electrical components 10.

QSK45 CM500 and QSK60 CM500

For the QSK45 CM500 and QSK60 CM500 engines, the Electrical Connector Adapter 3408509 plays a pivotal role in maintaining the integrity of the engine’s electrical architecture. These engines, known for their robust performance and reliability, benefit from the adapter’s precision engineering, which ensures that electrical signals are transmitted accurately and without interference. The adapter’s design allows for easy integration with the engine’s existing electrical connectors, providing a secure and stable connection that is essential for optimal engine operation 11.

QSK60G

The QSK60G engine, another high-performance model in Cummins’ lineup, also relies on the Electrical Connector Adapter 3408509 to manage its complex electrical network. This adapter is engineered to handle the specific electrical demands of the QSK60G, ensuring that all electrical components are properly connected and functioning as intended. The adapter’s compatibility with the QSK60G’s electrical system is crucial for maintaining the engine’s efficiency and reliability, particularly in demanding applications where electrical performance can significantly impact overall engine operation 12.

Role of Part 3408509 Electrical Connector Adapter in Engine Systems

The part 3408509 Electrical Connector Adapter is integral to the seamless operation of various engine systems, particularly when interfacing with the Engine Control Module (ECM). This adapter facilitates the connection between the ECM and other electrical components within the engine system, ensuring that data and power are efficiently transmitted.

In the context of the engine control system, the adapter plays a significant role in maintaining the integrity of the electrical connections. It ensures that the ECM receives accurate data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. This data is essential for the ECM to make precise adjustments to the fuel injection and ignition timing, optimizing engine performance and efficiency 13.

Furthermore, the adapter supports the communication between the ECM and actuators like the fuel injectors, throttle body, and various solenoids. This reliable connection ensures that the ECM’s commands are executed promptly and accurately, contributing to smooth engine operation and responsive throttle control 14.

Additionally, the adapter is involved in the connection to the vehicle’s onboard diagnostics (OBD) system. It allows for the transmission of diagnostic trouble codes (DTCs) from the ECM to the OBD port, enabling mechanics to perform thorough diagnostics and maintenance 15.

Conclusion

The 3408509 Electrical Connector Adapter is a vital component in the electrical systems of commercial trucks and Cummins engines. Its role in ensuring reliable connections between various electrical components contributes to the overall efficiency and reliability of the vehicle’s systems. By understanding the key features, benefits, and proper installation and maintenance of this Cummins part, vehicle operators and technicians can ensure optimal performance and longevity of the electrical systems in their vehicles.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩ -

Cummins Inc. Engine L9 CM2670 L132B, Service Manual (5660060).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.