This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

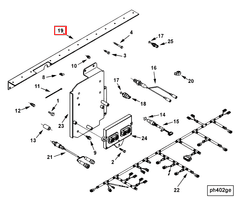

The Electronic Control Module Bracket (Part #3607766) by Cummins is a component designed to support and secure the Electronic Control Module (ECM) in heavy-duty trucks. This Cummins part plays a significant role in ensuring the ECM remains properly positioned and protected within the vehicle’s electronic system. Manufactured by Cummins, a well-established name in the automotive industry, this bracket is engineered to meet the rigorous demands of heavy-duty applications.

Function and Operation

The Electronic Control Module Bracket serves as a foundational support structure for the ECM. It plays a role in the truck’s electronic system by providing a stable mounting point for the ECM, which is responsible for managing various engine and vehicle functions 1. By securing the ECM, the bracket helps maintain the integrity of the electronic connections and protects the module from physical damage and environmental factors. This support contributes to the overall performance and reliability of the vehicle’s electronic system.

Key Features

The design and material characteristics of the Electronic Control Module Bracket are tailored to meet the specific needs of heavy-duty trucks. Constructed from durable materials, the bracket is capable of withstanding the vibrations and harsh conditions typical of such environments 2. It features precise mounting provisions that ensure a secure fit for the ECM, facilitating easy installation and integration with other components. The bracket’s design also allows for efficient heat dissipation, contributing to the ECM’s operational stability.

Benefits

The Electronic Control Module Bracket offers several advantages. It provides enhanced protection for the ECM, safeguarding it against physical impacts and environmental elements. This protection contributes to improved system reliability and longevity 3. Additionally, the bracket’s design facilitates ease of installation, allowing for straightforward integration into the vehicle’s electronic system. Its robust construction ensures durability, reducing the need for frequent replacements and maintenance.

Installation and Maintenance

Proper installation of the Electronic Control Module Bracket is crucial for ensuring optimal performance. It is recommended to follow manufacturer guidelines for installation procedures, utilizing appropriate tools to secure the bracket and ECM in place. Regular maintenance checks are advised to ensure the bracket remains securely mounted and free from damage. Cleaning the bracket and surrounding areas can prevent the accumulation of debris that might affect performance.

Troubleshooting Common Issues

Frequent problems associated with the Electronic Control Module Bracket may include loose mounting, damage from impacts, or corrosion. Diagnostic steps should begin with a visual inspection of the bracket and its mounting points. Ensuring the bracket is securely fastened and free from physical damage is important. In cases of corrosion, cleaning the affected areas and applying a protective coating can help mitigate further degradation. If issues persist, consulting the vehicle’s service manual or seeking professional assistance is recommended.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly for its heavy-duty truck components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted provider in the automotive sector.

Engine Compatibility with Electronic Control Module Bracket (Part 3607766)

The Electronic Control Module (ECM) Bracket, identified by the part number 3607766 and manufactured by Cummins, is a critical component in the installation and operation of the ECM within various engine models. This bracket ensures the ECM is securely mounted, providing stability and protection to the sensitive electronic control unit.

Cummins QSK19G

The Cummins QSK19G engine is a robust, high-performance diesel engine designed for demanding applications. The ECM Bracket 3607766 is specifically engineered to fit seamlessly with the QSK19G, ensuring that the ECM is positioned correctly to interface with the engine’s control systems. This bracket’s design accommodates the unique layout and requirements of the QSK19G, facilitating efficient communication between the ECM and the engine’s various subsystems.

Group Compatibility

The ECM Bracket 3607766 is not limited to a single engine model but is designed to be compatible with a range of Cummins engines. This versatility allows the bracket to be used across different engine groups, providing a standardized solution for ECM mounting. The bracket’s design ensures it can adapt to the specific spatial and mechanical requirements of each engine model within the group, maintaining the integrity and functionality of the ECM.

Installation Considerations

When installing the ECM Bracket 3607766, it is essential to follow the manufacturer’s guidelines to ensure proper fitment and function. The bracket must be securely fastened to the engine block, providing a stable platform for the ECM. Proper installation is crucial for maintaining the ECM’s operational efficiency and protecting it from environmental factors that could compromise its performance.

Role of Part 3607766 Electronic Control Module Bracket in Engine Systems

The part 3607766 Electronic Control Module (ECM) Bracket is an integral component in the assembly and operation of modern engine systems. It provides a secure mounting point for the ECM, ensuring that the module remains stable and protected during engine operation.

Integration with the Engine Control Module

The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The ECM Bracket ensures that the module is correctly positioned and isolated from engine vibrations, which could otherwise interfere with its sensitive electronic components.

Supporting Engine Control Functions

By securely mounting the ECM, the bracket plays a significant role in maintaining the integrity of the engine control functions. The ECM relies on consistent and accurate data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor. The stable mounting provided by the bracket helps ensure that these sensors can transmit reliable data to the ECM, allowing for precise control over fuel injection, ignition timing, and emissions.

Enhancing System Reliability

The ECM Bracket also contributes to the overall reliability of the engine system. By keeping the ECM firmly in place, it reduces the risk of electrical connections becoming loose, which could lead to intermittent issues or complete system failures. This is particularly important in high-vibration environments typical of automotive and industrial engine applications.

Facilitating Maintenance and Diagnostics

From a maintenance perspective, the ECM Bracket makes it easier to access the ECM for diagnostics and repairs. Technicians can quickly locate and remove the module for testing or replacement, minimizing downtime and simplifying the repair process. This accessibility is vital for timely maintenance and ensures that the engine system can be quickly returned to optimal performance.

Conclusion

In summary, the part 3607766 ECM Bracket is a key component in the engine system, providing essential support and stability for the ECM. Its role in maintaining the accuracy and reliability of engine control functions underscores its importance in modern engine design.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.