This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

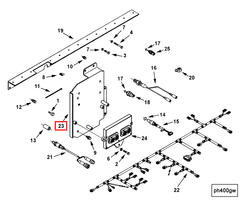

The 3607969 Electronic Control Module (ECM) Bracket by Cummins is a component designed to support and protect the ECM in commercial trucks. This bracket plays a role in ensuring the ECM operates efficiently within the truck’s electronic system. Cummins Inc., the manufacturer, is renowned for its expertise in diesel engines and components, providing reliable solutions for the commercial truck industry 1.

Basic Concepts of Electronic Control Module Brackets

An Electronic Control Module (ECM) Bracket serves as a mounting and protective structure for the ECM. It interfaces with various components within the truck’s electronic system, ensuring the ECM remains securely in place and is shielded from environmental factors. The ECM, a critical component, manages engine functions and communicates with other systems to optimize performance 2.

Purpose of the 3607969 Electronic Control Module Bracket

The 3607969 ECM Bracket is specifically designed to enhance the functionality and protection of the ECM in commercial trucks. It provides a stable mounting solution, ensuring the ECM is properly positioned and protected from vibrations, impacts, and harsh environmental conditions. This contributes to the overall reliability and performance of the truck’s electronic system 3.

Key Features

The 3607969 ECM Bracket features a robust construction, typically made from high-strength materials to ensure durability. Its design includes precise mounting points and secure attachment mechanisms to accommodate the ECM effectively. Additionally, the bracket may incorporate features such as vibration dampening elements and protective covers to enhance its performance and longevity 4.

Benefits

The 3607969 ECM Bracket offers several benefits, including improved protection for the ECM, which helps maintain the integrity of the truck’s electronic system. Its design facilitates ease of installation, allowing for straightforward integration with the truck’s existing systems. Furthermore, by ensuring the ECM remains secure and protected, the bracket can contribute to enhanced truck performance and reliability 2.

Installation Process

Installing the 3607969 ECM Bracket involves several steps. Begin by ensuring the truck’s engine compartment is clean and free of debris. Locate the designated mounting points for the bracket and use the appropriate tools to secure it in place. Carefully position the ECM within the bracket, ensuring all connections are properly aligned. Finally, verify that the bracket is firmly attached and that the ECM is correctly installed and operational 3.

Troubleshooting and Maintenance

To troubleshoot common issues with the 3607969 ECM Bracket, inspect the bracket for signs of wear or damage, such as cracks or loose mounting points. Ensure all connections are secure and that the ECM is properly seated within the bracket. Regular maintenance includes checking the bracket’s condition and tightening any loose fasteners. If any damage is detected, consider replacing the bracket to prevent potential ECM malfunctions 4.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer with a rich history in the diesel engine and component industry. Known for its innovation and reliability, Cummins provides a wide range of products designed to enhance the performance and efficiency of commercial trucks. The company’s reputation is built on its commitment to quality and customer satisfaction, making it a trusted name in the industry 1.

Cummins Electronic Control Module Bracket (Part 3607969)

The Cummins Electronic Control Module (ECM) Bracket, identified by part number 3607969, is a critical component in the installation and operation of the ECM within various Cummins engine models. This bracket ensures the ECM is securely mounted and positioned correctly within the engine compartment, facilitating optimal performance and reliability 1.

Application in Cummins Engines

QSK19G

The QSK19G engine, known for its robust design and high performance, integrates the ECM Bracket 3607969 to maintain the ECM’s structural integrity. This bracket is essential in protecting the ECM from vibrations and environmental factors that could compromise its functionality. By providing a stable mounting point, it ensures that the ECM remains in the correct orientation, which is vital for accurate engine management and diagnostics 1.

Other Cummins Engines

While the QSK19G is highlighted, the ECM Bracket 3607969 is also applicable to a range of other Cummins engines. This part is designed to fit seamlessly within the engine architecture of various models, ensuring compatibility and ease of installation. The bracket’s design allows for precise alignment of the ECM, which is crucial for the engine’s electronic systems to operate efficiently 1.

The ECM Bracket 3607969 is engineered to meet the stringent requirements of Cummins engines, ensuring that it can withstand the operational stresses and conditions these engines encounter. Its robust construction and precise fitment contribute to the overall reliability and performance of the engine, making it an indispensable part of the engine’s electronic control system 1.

Integration of Part 3607969 Electronic Control Module Bracket with Engine Systems

The part 3607969 Electronic Control Module (ECM) Bracket is designed to provide a secure mounting solution for the ECM within various engine systems. This bracket ensures that the ECM is properly positioned and protected, allowing it to interact effectively with other components 2.

When installed, the ECM Bracket supports the ECM in a manner that facilitates its connection to the Engine Control Module (ECM). This connection is essential for the ECM to receive and process data from various sensors distributed throughout the engine system. The ECM, in turn, uses this data to make real-time adjustments to engine performance, ensuring optimal operation 2.

The bracket also plays a role in maintaining the structural integrity of the ECM. By securing the ECM firmly in place, the bracket helps to protect it from vibrations and impacts that could otherwise disrupt its function or cause physical damage. This is particularly important in high-vibration environments typical of engine compartments 3.

Additionally, the ECM Bracket aids in the organization of wiring harnesses connected to the ECM. By keeping these wires neatly routed and secured, the bracket reduces the risk of wire chafing or disconnection, which could lead to intermittent issues or complete failure of the engine control system 4.

Conclusion

In summary, the part 3607969 ECM Bracket is an integral component in the engine system, ensuring the ECM is correctly positioned, protected, and connected, thereby contributing to the overall reliability and performance of the engine 1234.

-

Gunnar Stiesch, Modeling Engine Spray and Combustion Processes, Springer Verlag, 2003.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems, Wiley, 2022.

↩ ↩ ↩ ↩ ↩ -

Matthew Huang, Vehicle Crash Dynamics, CRC Press, 2002.

↩ ↩ ↩ ↩ -

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing Limited, 2011.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.