3634068

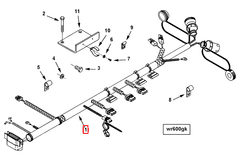

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #3634068) by Cummins is a vital component in the electrical system of commercial trucks. It serves as the conduit for electrical signals between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This wiring harness is integral to the operation of the truck, ensuring that the ECM can effectively monitor and control engine functions, thereby contributing to overall vehicle performance and efficiency 1.

Basic Concepts

Electronic Control Module Wiring Harnesses are fundamental to the electrical architecture of modern vehicles. They facilitate the transmission of data and power between the ECM and other electronic components. Within the vehicle’s electrical system, these harnesses interact with sensors that provide real-time data to the ECM and with actuators that execute commands from the ECM. This interaction allows for precise control over engine operations, emissions, and other critical functions 2.

Purpose and Role

The Electronic Control Module Wiring Harness is designed to connect the ECM to a network of sensors and actuators. Its role is to ensure seamless communication between these components, allowing the ECM to receive data from sensors and send commands to actuators. This connectivity is crucial for the ECM to perform its functions, such as adjusting fuel injection timing, regulating engine speed, and managing emissions controls 3.

Key Features

The 3634068 is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typical of commercial truck environments, including exposure to vibrations, temperature extremes, and moisture. The harness is constructed with durable insulation and corrosion-resistant connectors, enhancing its performance and longevity 4.

Benefits

Utilizing the 3634068 offers several advantages. It contributes to improved engine performance by ensuring reliable communication between the ECM and other components. Enhanced diagnostic capabilities are another benefit, as the harness allows for more accurate monitoring and troubleshooting of engine functions. Additionally, its robust construction increases the reliability of the electrical system, reducing the likelihood of failures 5.

Installation and Compatibility

Proper installation of the 3634068 is crucial for its effective operation. It is designed to be compatible with a range of Cummins engine models and integrates seamlessly with various truck systems. Installation procedures should follow manufacturer guidelines to ensure correct placement and secure connections, which are vital for the harness’s performance and the overall functionality of the truck’s electrical system 6.

Troubleshooting and Maintenance

To maintain the 3634068 in optimal condition, regular inspections and maintenance are recommended. Troubleshooting common issues may involve checking for loose connections, inspecting the harness for signs of wear or damage, and ensuring that all components are functioning as intended. Adhering to maintenance schedules and addressing any identified issues promptly can help ensure the longevity and reliable operation of the wiring harness 7.

Common Failures and Solutions

Common failure modes for the 3634068 may include connector corrosion, wire abrasion, and insulation degradation. Addressing these issues may involve cleaning or replacing corroded connectors, repairing or replacing damaged wires, and ensuring that the harness is properly routed to avoid further abrasion. Regular maintenance and inspections can help identify potential problems early, allowing for timely repairs 8.

Diagnostic Techniques

Diagnostic techniques for the 3634068 may include visual inspections, continuity tests, and the use of diagnostic tools to monitor ECM communications. These methods can help identify issues such as open circuits, short circuits, or intermittent connections. Employing the appropriate diagnostic tools and techniques is crucial for accurately assessing the condition of the wiring harness and ensuring its proper function 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial transportation, construction, and industrial applications 10.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3634068 and manufactured by Cummins, is a critical component that ensures seamless communication between the ECM and various sensors and actuators within the engine system. This wiring harness is designed to be compatible with a range of Cummins engines, ensuring that the electrical signals are transmitted efficiently and accurately.

K50 Series Engines

For the K50 series engines, the ECM Wiring Harness 3634068 is engineered to interface with the engine’s electronic control unit, facilitating the transfer of data between the ECM and other electronic components. This compatibility is crucial for maintaining optimal engine performance and ensuring that the engine operates within specified parameters.

The K50 series engines, known for their robust design and reliability, benefit significantly from the precise electrical connections provided by this wiring harness. The harness is designed to withstand the rigors of engine operation, including exposure to high temperatures and vibrations, ensuring long-term durability and performance.

Group Compatibility

The ECM Wiring Harness 3634068 is also compatible with other Cummins engine groups that utilize similar electronic control systems. This broad compatibility allows for easier maintenance and repair, as technicians can use a single wiring harness model across multiple engine types, reducing inventory needs and simplifying the repair process.

By ensuring that the ECM Wiring Harness 3634068 is properly connected to the ECM and other components, engine operators can maintain the integrity of the engine’s electronic systems, leading to improved efficiency and reduced downtime.

Role of Part 3634068 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 3634068, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, ensuring seamless communication and operation.

Integration with Engine Components

-

Wiring: The harness is meticulously designed to interface with the engine’s wiring system. It provides the necessary electrical connections that allow the ECM to monitor and control engine functions. This includes power delivery, sensor data transmission, and actuator commands.

-

Electronic Control Module (ECM): At the heart of the engine’s electronic system, the ECM relies on the wiring harness to receive data from sensors and send signals to actuators. This bidirectional flow of information is essential for the ECM to make real-time adjustments to engine performance.

-

Harness: The harness itself is a complex network of wires, connectors, and terminals. It is engineered to withstand the harsh environment of the engine compartment, ensuring reliable performance over the vehicle’s lifespan.

-

Accessories: Many engine accessories, such as the fuel pump, ignition system, and emission control devices, are controlled or monitored via the ECM Wiring Harness. This integration allows for optimized performance and efficiency.

-

Electronic Step (24V) Kit: In systems requiring higher voltage, such as 24V electronic step kits, the ECM Wiring Harness facilitates the necessary connections. This ensures that the ECM can effectively manage the increased electrical demands of these components.

Functionality in Engine Systems

The ECM Wiring Harness plays a significant role in the following engine system functionalities:

- Sensor Data Transmission: It carries signals from various sensors (e.g., oxygen sensors, temperature sensors) to the ECM, allowing for precise monitoring of engine conditions.

- Actuator Control: It transmits commands from the ECM to actuators (e.g., fuel injectors, throttle bodies), enabling the ECM to adjust engine parameters in real-time.

- Power Distribution: It ensures that power is efficiently distributed to all connected components, maintaining optimal engine performance.

- System Integration: It integrates with other electronic systems, such as the transmission control module and anti-lock braking system, enhancing overall vehicle performance and safety.

Conclusion

In summary, the ECM Wiring Harness (part 3634068) is a foundational component in modern engine systems, facilitating essential communication and control between the ECM and various engine components. Its robust design, compatibility with a range of Cummins engines, and critical role in engine performance make it an indispensable part of commercial truck electrical systems.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Modern Diesel Technology Heavy Equipment Systems, Delmar Cengage Learning, 2014

↩ -

Engine Testing: Theory and Practice: Third Edition, SAE International, 2007

↩ -

General Information, Bulletin Number 4021490, Operation and Maintenance Manual

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Modern Diesel Technology Heavy Equipment Systems, Delmar Cengage Learning, 2014

↩ -

Engine Testing: Theory and Practice: Third Edition, SAE International, 2007

↩ -

General Information, Bulletin Number 4021490, Operation and Maintenance Manual

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Modern Diesel Technology Heavy Equipment Systems, Delmar Cengage Learning, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.