3637139

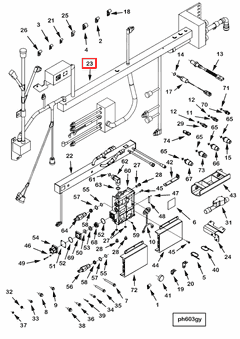

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #3637139) by Cummins is a vital component in the operation of heavy-duty trucks. This wiring harness is designed to facilitate communication between the Electronic Control Module (ECM) and various other components within the truck. Cummins, a well-established manufacturer in the automotive industry, produces this part with a focus on reliability and performance.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing and regulating various operations to ensure optimal performance. It processes data from sensors and other inputs to control engine functions, transmission shifts, and other operations. The wiring harness plays a role in this system by providing the necessary electrical connections between the ECM and other components. It ensures that signals and power are transmitted efficiently and accurately throughout the truck.

Purpose of the 3637139 Electronic Control Module Wiring Harness

The 3637139 Electronic Control Module Wiring Harness is integral to the operation of a truck. It facilitates communication between the ECM and other truck components, ensuring that all systems work in harmony. This wiring harness allows for the transmission of data and power, enabling the ECM to monitor and control various functions such as engine performance, fuel efficiency, and emissions. By providing a reliable connection, it helps maintain the overall efficiency and performance of the truck.

Key Features

The 3637139 Electronic Control Module Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear and environmental factors. The design includes robust connectors and insulation to ensure reliable signal transmission. Additionally, the harness is engineered to withstand the vibrations and harsh conditions typical in heavy-duty truck operations, ensuring long-lasting performance.

Benefits

Using the 3637139 Electronic Control Module Wiring Harness offers several advantages. It contributes to improved reliability by ensuring stable and consistent communication between the ECM and other components. This results in enhanced overall performance of the truck. Additionally, the harness simplifies diagnostics by providing a structured pathway for data transmission, making it easier to identify and address any issues that may arise.

Installation and Integration

Proper installation and integration of the 3637139 Electronic Control Module Wiring Harness are crucial for ensuring its effectiveness. It is important to follow the manufacturer’s guidelines to ensure compatibility with other components within the truck’s system. Careful attention should be paid to securing all connections and ensuring that the harness is routed correctly to avoid any potential damage from moving parts or environmental factors.

Troubleshooting and Maintenance

When troubleshooting issues related to the 3637139 Electronic Control Module Wiring Harness, it is important to check for any loose connections, damaged wires, or signs of wear. Regular maintenance, such as inspecting the harness for any physical damage and ensuring all connections are secure, can help prevent issues and ensure longevity. Additionally, keeping the harness clean and free from debris can contribute to its optimal performance.

Safety Considerations

When working with the 3637139 Electronic Control Module Wiring Harness, it is important to follow safety guidelines to prevent accidents and ensure personal safety. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and the battery is disconnected before beginning any work, and avoiding working on the harness in wet or damp conditions to prevent electrical hazards.

Cummins Overview

Cummins is a reputable manufacturer with a long history in the automotive industry, particularly known for producing high-quality components for heavy-duty trucks. The company has built a strong reputation for reliability and performance, making it a trusted name among truck operators and maintenance professionals. Cummins continues to innovate and provide solutions that meet the demanding requirements of heavy-duty truck operations.

Role of Part 3637139 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness (part 3637139) serves as the vital connective tissue within an engine system, facilitating seamless communication and power distribution between the ECM and various engine components.

Integration with the Engine Control Module

The ECM Wiring Harness is meticulously designed to interface with the Engine Control Module, ensuring that the ECM receives accurate data from sensors and can effectively send control signals to actuators. This harness includes a network of wires, connectors, and terminals that allow the ECM to monitor and adjust engine operations in real-time.

Connection to Engine Sensors

Sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors are connected via the ECM Wiring Harness. These sensors provide essential data on air intake, fuel mixture, and exhaust emissions, allowing the ECM to make precise adjustments for optimal engine performance.

Actuator Control

The harness also extends to various actuators, including the fuel injectors, throttle body, and ignition coils. By transmitting signals from the ECM, the harness ensures that these components operate in harmony, enhancing fuel efficiency, reducing emissions, and improving overall engine responsiveness.

Power Distribution

In addition to data transmission, the ECM Wiring Harness is responsible for distributing power to the ECM and other electronic components. This includes providing a stable voltage supply to ensure consistent operation under varying engine loads and conditions.

Grounding and Shielding

To maintain signal integrity and protect against electromagnetic interference, the ECM Wiring Harness incorporates grounding wires and shielding. This ensures that the data transmitted between the ECM and engine components remains accurate and reliable, even in the presence of electrical noise.

Diagnostic Capabilities

The harness also plays a role in onboard diagnostics by providing connections to the On-Board Diagnostics (OBD) port. This allows for the retrieval of diagnostic trouble codes (DTCs), facilitating easier troubleshooting and maintenance.

Conclusion

In summary, the ECM Wiring Harness (part 3637139) is an indispensable component that ensures the ECM can effectively manage and optimize engine performance through precise data exchange and power distribution. Its robust design, integration capabilities, and diagnostic features make it a critical part of the engine system, contributing to the overall reliability and efficiency of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.