This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3637338 Electronic Control Module Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates the communication between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This harness ensures that the ECM receives accurate data from the sensors and can effectively control the truck’s systems, contributing to overall performance and efficiency 3.

Basic Concepts of Electronic Control Module Wiring Harnesses

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link the ECM to the truck’s various electrical components. It consists of multiple wires, each serving a specific function, bundled together for protection and organization. The harness allows for the transmission of data and power between the ECM and other systems, ensuring that the truck operates smoothly and efficiently 1. Components typically include insulated wires, connectors, and sometimes fuses or relays to manage electrical flow.

Role of the 3637338 Electronic Control Module Wiring Harness in Truck Operation

The Cummins 3637338 Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to interact with various systems. It provides the necessary connections for the ECM to receive input from sensors such as temperature, pressure, and position sensors. Additionally, it allows the ECM to send signals to actuators that control functions like fuel injection, engine timing, and emissions systems. This interaction ensures that the truck’s systems operate in harmony, optimizing performance and fuel efficiency 3.

Key Features of the 3637338 Wiring Harness

The Cummins 3637338 Wiring Harness is designed with several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to meet the demanding conditions of commercial truck operations, ensuring reliable performance over time. Additionally, it is designed for easy installation, with color-coded wires and clear labeling to simplify the connection process 2.

Benefits of Using the 3637338 Wiring Harness

Using the Cummins 3637338 Wiring Harness offers several benefits. It provides improved reliability by ensuring secure and consistent connections between the ECM and other components. This results in more accurate data transmission and better control over the truck’s systems. Additionally, the harness contributes to increased efficiency by optimizing the electrical system’s performance. Its design also facilitates easier installation and maintenance, reducing downtime and enhancing overall productivity 3.

Troubleshooting and Maintenance Suggestions

To maintain the Cummins 3637338 Wiring Harness in optimal condition, regular inspections are recommended. Check for signs of wear, corrosion, or damage to the wires and connectors. Ensure that all connections are secure and free from debris. If issues arise, such as intermittent signals or system malfunctions, inspect the harness for loose connections or damaged wires. Addressing these issues promptly can prevent more significant problems and ensure the truck’s continued reliable operation 1.

Integration with Cummins Engines

The Cummins 3637338 Wiring Harness is specifically designed to integrate seamlessly with Cummins engines. It features compatibility with various Cummins engine models, ensuring that it can effectively communicate with the ECM and other systems. The harness is engineered to meet the specific electrical requirements of Cummins engines, providing reliable and efficient operation. This integration enhances the overall performance and reliability of the truck’s engine system 3.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry. The company is committed to innovation, quality, and customer satisfaction, consistently delivering reliable and high-performance products. Cummins’ expertise in diesel engine manufacturing and its dedication to advancing technology make it a preferred choice for commercial truck operators 3.

Application in Specific Cummins Engines

QSK45 Engines

In the QSK45 engines, the ECM Wiring Harness plays a pivotal role in maintaining the engine’s operational efficiency. The QSK45 series, known for its robust performance and reliability, relies on this harness to manage the complex network of electrical signals that govern engine functions. The harness is meticulously engineered to withstand the demanding conditions of heavy-duty applications, ensuring durability and consistent performance 3.

CM500 Engines

Similarly, in the CM500 engines, the ECM Wiring Harness is integral to the engine’s control system. The CM500 series is designed for high-performance applications, and the wiring harness is a key element in this regard. It ensures that the ECM can effectively communicate with the engine’s sensors and actuators, facilitating precise control over engine operations. The harness is built to handle the rigors of continuous operation, providing a reliable connection that supports the engine’s demanding performance requirements 3.

Importance of the Wiring Harness

The ECM Wiring Harness is essential for the proper functioning of the engine’s electronic control system. It ensures that the ECM can receive real-time data from various sensors and send commands to the actuators, which is crucial for maintaining optimal engine performance. The harness’s design also includes protective measures to prevent damage from environmental factors, such as moisture and vibration, which are common in heavy-duty environments 3.

Role of Part 3637338 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3637338, is integral to the seamless operation of various engine systems. This harness acts as the central nervous system, facilitating communication and power distribution among different components.

Integration with Accessories

The ECM Wiring Harness is responsible for connecting the ECM to various accessories within the engine system. These accessories may include sensors, actuators, and other control devices. By providing a structured pathway for electrical signals, the harness ensures that the ECM can effectively monitor and control the operation of these accessories, enhancing the overall performance and reliability of the engine 3.

Electrical System Coordination

In the electrical system, the ECM Wiring Harness plays a pivotal role in coordinating the flow of power and data. It connects the ECM to the battery, alternator, and other electrical components, ensuring a stable power supply and efficient data transmission. This coordination is essential for the proper functioning of the engine’s electrical systems, including ignition, fuel injection, and emission control systems 3.

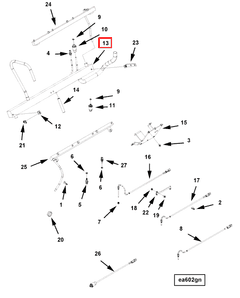

Harness Functionality

As a harness, part 3637338 is designed to protect and organize the myriad of wires that connect the ECM to other engine components. This organization prevents wire tangling and damage, which could lead to electrical faults. The harness also helps in reducing electromagnetic interference, ensuring that the signals transmitted between the ECM and other components are clear and accurate 2.

Engine Monitoring Wiring

The ECM Wiring Harness is a key component in the engine monitoring system. It connects the ECM to various sensors that monitor parameters such as engine temperature, oil pressure, and fuel levels. By providing a reliable connection, the harness ensures that the ECM receives real-time data, allowing it to make precise adjustments to the engine’s operation for optimal performance and efficiency 3.

Conclusion

In summary, the Cummins 3637338 Electronic Control Module Wiring Harness is essential for the integration and efficient operation of accessories, electrical systems, and engine monitoring wiring within the engine system. Its role in facilitating communication and power distribution underscores its importance in maintaining the engine’s performance and reliability 3.

-

Modern Diesel Technology Light Duty Diesels, Sean Bennett, Cengage Learning, 2012

↩ ↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.