This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3637462 Electronic Control Module Wiring Harness is a vital component in the operation of heavy-duty trucks, facilitating the communication between the Electronic Control Module (ECM) and various sensors and actuators. Manufactured by Cummins, a renowned name in the automotive industry, this wiring harness is designed to enhance the efficiency and performance of heavy-duty trucks. Cummins is well-known for its commitment to producing high-quality diesel engines and components, ensuring reliability and innovation in the automotive sector 2.

Basic Concepts of Electronic Control Module Wiring Harness

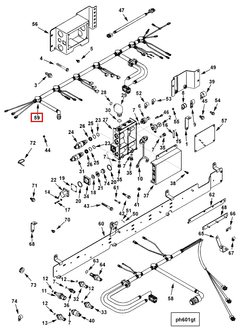

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to different sensors and actuators within the truck’s electrical system. This harness plays a role in transmitting signals and power between the ECM and other electronic components, ensuring that the truck operates efficiently. It consists of various components, including wires, connectors, and terminals, each designed to handle specific electrical tasks and ensure reliable communication within the system 1.

Purpose and Role in Truck Operation

The 3637462 Electronic Control Module Wiring Harness serves to facilitate seamless communication between the ECM and other electronic components in the truck. By providing a reliable pathway for signals and power, it ensures that the ECM can effectively monitor and control various functions such as engine performance, fuel efficiency, and emissions. This communication is vital for the optimal operation of the truck, allowing for adjustments and responses to changing conditions in real-time.

Key Features

The 3637462 Electronic Control Module Wiring Harness is characterized by its robust design and high build quality. It features durable materials that resist wear and corrosion, ensuring longevity and reliable performance. The harness is engineered to meet the demanding conditions of heavy-duty truck operations, with precise connectors and terminals that ensure secure and efficient connections. Additionally, its design allows for easy installation and maintenance, reducing downtime and enhancing overall truck performance.

Benefits

Utilizing the 3637462 Electronic Control Module Wiring Harness offers several benefits, including improved engine performance, enhanced fuel efficiency, and reliable operation. By ensuring efficient communication between the ECM and other components, it helps maintain optimal truck performance and reduces the likelihood of malfunctions. These benefits contribute to lower maintenance costs and extended truck longevity, making it a valuable component for fleet operators and truck owners.

Installation Process

Installing the 3637462 Electronic Control Module Wiring Harness involves several steps to ensure a proper and secure setup. Begin by identifying the correct location for the harness within the truck’s electrical system. Carefully route the wires to avoid interference with other components and secure them in place using appropriate fasteners. Ensure all connections are tight and secure, following the manufacturer’s guidelines to avoid common pitfalls such as loose connections or incorrect wiring. Testing the system post-installation is recommended to confirm proper functionality.

Troubleshooting Common Issues

Common issues with the Electronic Control Module Wiring Harness may include connectivity problems, electrical faults, and sensor malfunctions. To troubleshoot these issues, start by inspecting the wiring and connections for any signs of damage or corrosion. Use a multimeter to test for continuity and ensure that all connections are secure. If a sensor malfunction is suspected, check the sensor’s wiring and connections, and consider replacing the sensor if necessary. Regular inspections and maintenance can help prevent many of these issues.

Maintenance Tips

Regular maintenance of the 3637462 Electronic Control Module Wiring Harness is important to ensure its longevity and optimal performance. Inspect the harness for signs of wear and tear, corrosion, or loose connections on a routine basis. Clean the connectors and terminals to remove any dirt or debris that could interfere with signal transmission. Addressing any issues promptly can prevent more significant problems down the line and ensure the harness continues to function reliably.

Compatibility and Applications

The 3637462 Electronic Control Module Wiring Harness is designed for use in specific types of trucks and engines. It is compatible with various Cummins engine models and may also be suitable for other makes and models, depending on the specific requirements and configurations of the truck’s electrical system. Ensuring compatibility is important to maintain the integrity and performance of the truck’s electrical system.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and components, with a reputation for innovation and excellence in the automotive industry. Founded in 1919, Cummins has a long history of producing high-quality products that meet the demanding needs of heavy-duty applications. The company is committed to advancing technology and improving efficiency in the engines and components it produces, making it a trusted name in the industry 2.

Cummins Electronic Control Module Wiring Harness (Part 3637462) Compatibility

The Cummins Electronic Control Module Wiring Harness, identified by part number 3637462, is a critical component designed to ensure seamless electrical communication within the engine system. This wiring harness is engineered to interface with various Cummins engines, ensuring that electrical signals are transmitted efficiently and accurately.

QSK60 Engine Series

The QSK60 engine series, known for its robust performance and reliability, is one of the engines that benefit from the 3637462 wiring harness. This harness is meticulously designed to connect the Electronic Control Module (ECM) to other vital components within the engine, facilitating the exchange of data and control signals. The QSK60 series includes models such as the QSK60-G12, QSK60-G15, and QSK60-G17, all of which rely on this wiring harness for optimal operation.

CM500 Engine Series

Similarly, the CM500 engine series, which is recognized for its versatility and efficiency, is another beneficiary of the 3637462 wiring harness. This engine series includes models like the CM500-G12, CM500-G15, and CM500-G17. The wiring harness ensures that the ECM can communicate effectively with other engine components, enhancing overall performance and reliability.

Integration and Functionality

The integration of the 3637462 wiring harness with these engines is crucial for maintaining the integrity of the engine’s electrical system. It ensures that the ECM can send and receive signals from various sensors and actuators, enabling precise control over engine functions. This wiring harness is designed to withstand the rigors of engine operation, providing a durable and reliable connection that minimizes the risk of electrical faults.

Installation and Maintenance

Proper installation of the 3637462 wiring harness is essential to ensure that it functions correctly. Technicians should follow the manufacturer’s guidelines for installation, which typically include securing the harness in place, ensuring all connections are tight, and verifying that the harness is routed to avoid interference with moving parts. Regular maintenance checks should be performed to inspect for signs of wear or damage, ensuring that the harness remains in optimal condition.

Role of Part 3637462 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness (part 3637462) is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the seamless transmission of electrical signals and data.

Integration with the Engine Control Module

The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The ECM Wiring Harness connects the ECM to these sensors, actuators, and other control units, ensuring that the ECM receives accurate data and can send appropriate commands.

Connection to the Engine Control System

Within the engine control system, the harness interfaces with components such as the fuel injectors, ignition coils, and throttle position sensor. It allows the ECM to monitor and control fuel delivery, ignition timing, and air intake, optimizing engine performance and efficiency.

Role in the Harness Assembly

The ECM Wiring Harness is a key component of the brace and harness assembly. This assembly includes various harnesses and brackets that organize and protect the wiring throughout the engine bay. The ECM Wiring Harness is routed through this assembly, ensuring it remains secure and undamaged during engine operation.

Interaction with the Module

The harness directly connects to the ECM module, providing the necessary power and ground connections. It also facilitates communication between the ECM and other modules within the vehicle, such as the transmission control module and the anti-lock braking system module, enabling integrated vehicle control.

Ensuring Reliable Engine Operation

By providing a robust and reliable connection between the ECM and the engine’s electrical components, the ECM Wiring Harness plays a significant role in ensuring the engine operates smoothly and efficiently. It helps maintain the integrity of the electrical signals, reducing the risk of misfires, poor fuel economy, and other performance issues.

Conclusion

In summary, the ECM Wiring Harness (part 3637462) is essential for the proper functioning of the engine control system, enabling the ECM to effectively manage and optimize engine performance. Its robust design, ease of installation, and maintenance make it a valuable component for ensuring reliable and efficient engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.