3638772

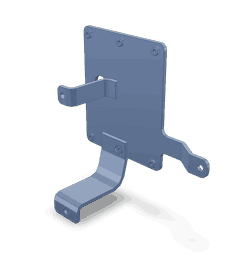

Electronic Control Module Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module (ECM) Bracket, part number 3638772, is a component manufactured by Cummins, a leader in diesel engine technology. This bracket plays a significant role in the electronic systems of commercial trucks, providing a secure mounting solution for the ECM. The ECM is a vital part of the truck’s electronic system, responsible for managing engine operations and ensuring optimal performance. Cummins, with its extensive experience and innovation in engine technology, ensures that this part meets the rigorous demands of commercial trucking environments 1.

Function and Operation

The ECM Bracket serves as a foundational component in the truck’s electronic system. It securely holds the ECM in place, protecting it from vibrations and environmental factors that could otherwise impair its function. By providing a stable platform for the ECM, the bracket contributes to the overall reliability and performance of the vehicle’s electronic systems. This stability is crucial for the ECM to accurately monitor and adjust engine parameters, ensuring efficient operation and longevity of the engine 2.

Key Features

This Cummins part is designed with durability and functionality in mind. Constructed from high-strength materials, it offers robust protection for the ECM. The bracket features precise mounting provisions that ensure a secure fit, minimizing the risk of damage to the ECM during operation. Its design is tailored to be compatible with Cummins engines, ensuring seamless integration into the engine management system 3.

Benefits

One of the primary advantages of the ECM Bracket is the enhanced protection it offers to the ECM. By securely mounting the ECM, the bracket helps prevent damage from vibrations and impacts, leading to improved system reliability. Additionally, the bracket’s design facilitates ease of installation, allowing for quick and straightforward mounting without the need for specialized tools. This not only saves time during maintenance but also reduces the potential for installation errors.

Installation Process

Installing the ECM Bracket requires attention to detail to ensure proper alignment and secure mounting. Begin by identifying the correct mounting location on the truck’s chassis. Use the provided hardware to attach the bracket, ensuring all bolts are tightened to the specified torque settings to prevent over-tightening or under-tightening. Align the ECM with the bracket’s mounting provisions and secure it in place. Double-check all connections and ensure the ECM is firmly attached before completing the installation.

Maintenance and Troubleshooting

Regular maintenance of the ECM Bracket involves inspecting it for signs of wear or damage, particularly after exposure to harsh conditions. Common issues may include loose mounting bolts or damage to the bracket itself. If any issues are detected, it is recommended to tighten the bolts or replace the bracket as necessary to maintain optimal performance. Ensuring the bracket remains in good condition is key to the longevity and reliability of the ECM and the overall electronic system.

Integration with Cummins Systems

The ECM Bracket is designed to integrate seamlessly with Cummins engine management systems. It adheres to Cummins’ communication protocols, allowing for efficient data exchange between the ECM and other components of the engine system. This integration ensures that the ECM can effectively monitor and adjust engine parameters, contributing to the engine’s performance and efficiency. System diagnostics are also facilitated through this integration, allowing for easier troubleshooting and maintenance.

Safety Considerations

When handling and installing the ECM Bracket, it is important to observe safety guidelines to prevent damage and ensure personal safety. Wear appropriate personal protective equipment (PPE) during installation to protect against injuries. Ensure the truck is securely parked on a level surface before beginning work. Follow all torque specifications provided by Cummins to avoid over-tightening, which can lead to bracket or ECM damage. Additionally, be mindful of electrical connections to prevent short circuits or damage to the ECM.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology, committed to innovation and sustainability. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and emission solutions. Cummins’ dedication to advancing diesel technology ensures that their components, like the ECM Bracket, meet the highest standards of quality and performance.

Conclusion

The ECM Bracket part number 3638772, manufactured by Cummins, is a critical component in the engine management system for commercial trucks. Its role in securely mounting the ECM ensures the stability and protection of the electronic control system, contributing to the overall reliability and performance of the vehicle. With its durable construction, ease of installation, and seamless integration with Cummins engine systems, this part exemplifies Cummins’ commitment to quality and innovation in diesel engine technology.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.