This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

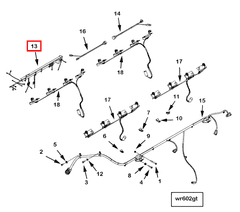

The 3640473 Electronic Control Module (ECM) Wiring Harness by Cummins is a vital component in the operation of heavy-duty trucks. This wiring harness facilitates the communication between the ECM and various sensors, actuators, and other electronic components within the truck. Its purpose is to ensure reliable and efficient data transmission, which is essential for the truck’s performance and functionality.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM to the truck’s electrical system. It consists of multiple wires, each serving a specific function, bundled together for organized and efficient routing. The harness includes connectors that interface with various components, ensuring seamless data flow and power distribution. Within the truck’s electrical system, the wiring harness plays a role by providing the necessary pathways for signals and power to travel between the ECM and other electronic components.

Role of the 3640473 Wiring Harness in Truck Operation

The 3640473 Wiring Harness is integral to the operation of a heavy-duty truck. It enables the ECM to receive data from sensors throughout the vehicle, such as those monitoring engine temperature, fuel levels, and emissions. The harness also allows the ECM to send commands to actuators, controlling functions like fuel injection timing and exhaust gas recirculation. By facilitating this two-way communication, the wiring harness ensures that the ECM can make real-time adjustments to optimize the truck’s performance, fuel efficiency, and emissions compliance.

Key Features of the 3640473 Wiring Harness

The 3640473 Wiring Harness is designed with several key features to enhance its functionality and durability. These include high-quality materials that resist wear and corrosion, ensuring long-term reliability. The harness is engineered to fit precisely within the truck’s chassis, minimizing the risk of damage from vibrations or harsh environmental conditions. Additionally, it is designed for easy integration with other components, simplifying the installation process and reducing the likelihood of errors.

Benefits of Using the 3640473 Wiring Harness

Utilizing the 3640473 Wiring Harness offers several benefits. Its robust construction and precise engineering contribute to improved reliability, reducing the likelihood of electrical failures. The efficient design of the harness enhances the overall performance of the truck’s electrical system, leading to better fuel efficiency and reduced emissions. Furthermore, the ease of installation and maintenance ensures that technicians can quickly address any issues, minimizing downtime and maintenance costs.

Installation Process

Installing the 3640473 Wiring Harness involves several steps to ensure proper integration with the truck’s electrical system. Begin by disconnecting the battery to prevent any electrical shorts. Next, route the harness through the designated pathways within the truck’s chassis, ensuring it is securely fastened at all points. Connect the harness to the ECM and other components using the provided connectors, making sure each connection is secure and properly aligned. Finally, reattach the battery and test the system to confirm that all connections are functioning correctly.

Common Issues and Troubleshooting

Common issues with the 3640473 Wiring Harness may include loose connections, damaged wires, or corrosion at the connectors. To address these problems, begin by inspecting all connections for signs of wear or damage. Ensure that each connector is fully seated and secure. If corrosion is present, clean the affected areas with a suitable contact cleaner. Replace any damaged wires or connectors as necessary to restore the integrity of the electrical system.

Maintenance Tips

To ensure the longevity and optimal performance of the 3640473 Wiring Harness, regular maintenance is recommended. Inspect the harness periodically for signs of wear, corrosion, or damage. Clean the connectors as needed to prevent buildup that could interfere with signal transmission. Ensure that the harness is properly secured within the truck’s chassis to protect it from vibrations and environmental factors. By following these maintenance tips, you can help ensure the reliable operation of the wiring harness and the overall electrical system of the truck.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry, particularly in the production of diesel engines and related components. The company offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. Cummins is committed to quality and innovation, continually advancing its technologies to improve performance, efficiency, and reliability. The 3640473 Wiring Harness is a testament to Cummins’ dedication to providing high-quality, dependable components for the automotive industry.

Cummins Engine Compatibility with Electronic Control Module Wiring Harness Part 3640473

The Electronic Control Module (ECM) Wiring Harness part number 3640473, manufactured by Cummins, is a critical component for the proper functioning of several Cummins engine models. This wiring harness is designed to facilitate the electrical communication between the ECM and various engine sensors and actuators, ensuring seamless operation and optimal performance.

QSK50 Engines

The QSK50 series engines, known for their robust design and high power output, are compatible with the ECM Wiring Harness part 3640473. This harness is engineered to interface with the QSK50’s sophisticated electronic control systems, providing the necessary electrical pathways for data transmission and control signals. The integration of this wiring harness is crucial for maintaining the engine’s efficiency and reliability.

CM2150 Engines

The CM2150 engines, which are part of Cummins’ medium-duty diesel engine lineup, also benefit from the ECM Wiring Harness part 3640473. This harness is specifically designed to work with the CM2150’s electronic architecture, ensuring that all necessary components are properly connected and that the engine can operate at peak performance. The compatibility of this wiring harness with the CM2150 series is essential for the engine’s diagnostic capabilities and overall functionality.

MCRS Engines

The MCRS (Modular Common Rail System) engines, which are part of Cummins’ advanced diesel engine technology, are another series that can utilize the ECM Wiring Harness part 3640473. This harness is tailored to the MCRS’s modular design, providing the necessary electrical connections for the engine’s common rail fuel injection system. The use of this wiring harness is vital for the MCRS engines to achieve the desired fuel efficiency and power output.

In summary, the ECM Wiring Harness part 3640473 is a versatile and essential component for several Cummins engine models, including the QSK50, CM2150, and MCRS series. Its design ensures that these engines can operate efficiently and reliably by providing the necessary electrical connections for the ECM and other critical components.

Role of Part 3640473 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3640473, is integral to the operation of modern engine systems. This harness serves as the vital communication network between the ECM and various engine components, ensuring seamless data exchange and control.

Integration with Engine Components

-

Sensors: The harness connects a multitude of sensors—such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors—to the ECM. These sensors provide real-time data on air intake, pressure, and exhaust gas composition, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. The ECM uses data from sensors to send signals through the harness to these actuators, controlling fuel injection timing, air intake volume, and valve timing for optimal engine performance.

-

Ignition System: The harness links the ECM to the ignition coils and spark plugs. It transmits signals for spark timing, ensuring that the fuel-air mixture ignites at the precise moment for maximum efficiency and power.

-

Emission Control Systems: It also connects to components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This allows the ECM to monitor and control emissions, ensuring compliance with environmental regulations.

-

Battery and Alternator: The harness includes connections to the battery and alternator, facilitating the monitoring of electrical system health and ensuring stable voltage supply to the ECM and other electronic components.

-

Communication Networks: In more advanced engine systems, the harness may also integrate with vehicle communication networks such as Controller Area Network (CAN) bus systems. This allows the ECM to communicate with other vehicle control modules, enhancing overall vehicle performance and diagnostics.

By providing a robust and reliable connection between the ECM and these critical engine components, the ECM Wiring Harness ensures that the engine operates efficiently, responds accurately to driving conditions, and maintains optimal performance throughout its operational life.

Conclusion

The 3640473 Electronic Control Module Wiring Harness by Cummins is a critical component for the efficient and reliable operation of heavy-duty trucks and various Cummins engine models. Its robust design, precise engineering, and compatibility with a range of engine systems make it an essential part of modern automotive technology. Regular maintenance and proper installation are key to ensuring the longevity and performance of this vital component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.