This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

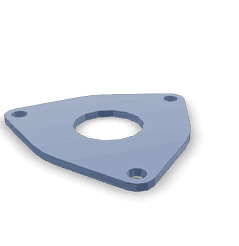

The Cummins 3641522 Coolant Flow Metering Orifice is a component designed to regulate the flow of coolant within the cooling system of heavy-duty trucks. Its purpose is to maintain optimal engine temperature by controlling the rate at which coolant passes through the system. This ensures that the engine operates within safe temperature limits, enhancing overall performance and longevity.

Basic Concepts of Coolant Flow Metering Orifice

A Coolant Flow Metering Orifice is a small, precisely-sized opening that restricts the flow of coolant. This restriction helps to manage the coolant’s velocity and pressure, which are important factors in the efficient operation of the engine cooling system. By regulating coolant flow, the orifice contributes to maintaining a consistent engine temperature, which is vital for the engine’s performance and durability 1.

Purpose of the 3641522 Coolant Flow Metering Orifice

The 3641522 Coolant Flow Metering Orifice plays a role in the operation of a truck by regulating the flow of coolant to ensure efficient engine cooling. It is positioned in the coolant pathway to create a controlled restriction, which helps in balancing the coolant distribution between the engine and the radiator. This balanced flow is important for dissipating heat effectively and preventing overheating 2.

Key Features

The 3641522 Coolant Flow Metering Orifice is characterized by its precise design and durable material, which are selected to withstand the high temperatures and pressures within the engine cooling system. Its unique characteristics include a specific orifice size that is calibrated to provide the optimal restriction for efficient coolant flow. This design ensures that the orifice can perform reliably under various operating conditions 3.

Benefits

Using the 3641522 Coolant Flow Metering Orifice offers several benefits. It contributes to improved engine efficiency by ensuring that the engine maintains an optimal operating temperature. This regulation reduces the risk of overheating, which can lead to engine damage. Additionally, the orifice enhances the overall performance of the cooling system by promoting consistent coolant flow and temperature management 4.

Installation Process

Installing the 3641522 Coolant Flow Metering Orifice requires careful attention to ensure proper fitting and function. The process involves locating the correct position within the coolant pathway, using the appropriate tools to secure the orifice in place, and ensuring that all connections are tight to prevent leaks. It is important to follow the manufacturer’s guidelines for installation to ensure the orifice operates as intended 5.

Troubleshooting Common Issues

Common problems with the 3641522 Coolant Flow Metering Orifice may include blockages or leaks. Blockages can occur due to debris in the coolant, while leaks may result from improper installation or wear over time. Troubleshooting steps include inspecting the orifice for signs of damage or obstruction, cleaning the coolant system if necessary, and re-securing or replacing the orifice as needed to restore proper function.

Maintenance Tips

Regular maintenance of the 3641522 Coolant Flow Metering Orifice is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the orifice to remove any buildup that may affect its function, and ensuring that all connections remain secure. Adhering to a maintenance schedule helps to prevent issues and ensures the cooling system operates efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components that are designed to meet the demanding requirements of various applications, ensuring reliable performance and durability.

Coolant Flow Metering Orifice (Part 3641522) in Cummins Engines

The Coolant Flow Metering Orifice (part 3641522) is a critical component in the cooling systems of various Cummins engines, ensuring optimal coolant flow and temperature regulation. This part is integral to the performance and longevity of the engines, particularly in the QSK60, CM850, and MCRS series.

QSK60 Series

In the QSK60 series, the Coolant Flow Metering Orifice is designed to manage the coolant flow efficiently, maintaining the engine’s optimal operating temperature. This is crucial for preventing overheating and ensuring the engine operates at peak performance. The QSK60 engines, known for their robust design and high power output, benefit significantly from the precise control provided by this orifice.

CM850 Series

The CM850 series engines also rely on the Coolant Flow Metering Orifice to regulate coolant flow. These engines are typically used in heavy-duty applications, where consistent and reliable performance is essential. The orifice ensures that the coolant circulates effectively, protecting the engine from thermal stress and maintaining efficiency.

MCRS Series

The MCRS series engines, which are often used in marine applications, also incorporate the Coolant Flow Metering Orifice. In marine environments, where engines are exposed to varying temperatures and conditions, this part plays a vital role in maintaining the engine’s cooling system’s integrity. The orifice helps in achieving the precise coolant flow necessary for the engine’s optimal performance in these demanding conditions.

Grouping Considerations

While the Coolant Flow Metering Orifice is a common component across these engines, its specific design and placement may vary slightly to accommodate the unique requirements of each engine series. The QSK60 and CM850 series, both designed for heavy-duty applications, share similarities in their cooling system requirements, making the orifice a critical part for both. The MCRS series, with its focus on marine applications, also benefits from this component, ensuring that the engine can handle the unique thermal challenges of marine environments.

Role of Part 3641522 Coolant Flow Metering Orifice in Engine Systems

The Coolant Flow Metering Orifice, identified by part number 3641522, is integral to the efficient operation of engine cooling systems. This component is strategically positioned within the coolant flow path to regulate and meter the flow of coolant to various engine components.

Interaction with the Water Outlet

The Coolant Flow Metering Orifice is typically installed in close proximity to the water outlet. Its primary function here is to control the rate at which coolant is distributed from the water outlet to different parts of the engine. By metering the coolant flow, it ensures that each component receives the appropriate amount of coolant necessary for optimal cooling and performance. This precise control helps maintain consistent engine temperatures, which is essential for the longevity and efficiency of the engine.

Connection Points

The orifice is designed to fit into specific connection points within the engine’s coolant system. These connection points are usually located between the water outlet and other critical components such as the cylinder head, radiator, or heater core. The orifice’s placement at these junctions allows it to effectively manage the coolant distribution, preventing any single component from receiving too much or too little coolant. This balanced distribution is key to preventing hotspots and ensuring uniform cooling across the engine.

Conclusion

The Coolant Flow Metering Orifice (part 3641522) plays a significant role in the engine’s cooling system by regulating coolant flow at critical connection points, particularly near the water outlet. Its accurate metering capabilities contribute to the overall efficiency and reliability of the engine cooling process.

-

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007

↩ -

A Field Guide to Automotive Technology, Ed Sobey, Chicago Review Press, 2009

↩ -

Synthesis Lectures on Advances in Automotive Technology, Amir Khajepour, Springer, 2023

↩ -

Fundamentals of Vehicle Dynamics, Thomas D. Gillespie, SAE International, 2021

↩ -

General Information, Bulletin Number 4021418, Troubleshooting and Repair Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.