This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

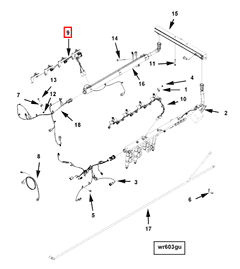

The Cummins 3641610 Electronic Control Module Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital link in the electrical system, facilitating communication between the Electronic Control Module (ECM) and various sensors and actuators throughout the vehicle. This wiring harness is integral to the efficient and reliable operation of the truck, ensuring that all electronic systems function cohesively.

Basic Concepts of Electronic Control Module Wiring Harnesses

An Electronic Control Module Wiring Harness is a bundle of wires and connectors that transmit electrical signals between the ECM and other electronic components within the truck. It consists of multiple wires, each serving a specific function, encased in a protective sheath. The harness is designed to withstand the harsh conditions typically encountered in commercial trucking, including vibrations, temperature fluctuations, and exposure to chemicals 1.

Role of the 3641610 Wiring Harness in Truck Operation

The 3641610 Wiring Harness plays a significant role in the operation of a truck by providing the necessary electrical connections for the ECM to communicate with various systems. This includes engine management, transmission control, braking systems, and emissions control. The harness ensures that data is accurately transmitted, allowing the ECM to make real-time adjustments to optimize performance, fuel efficiency, and emissions compliance 2.

Key Features of the 3641610 Wiring Harness

The 3641610 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to corrosion and wear. The harness is also designed to be flexible, allowing it to be routed through the truck’s chassis without compromising its integrity. Additionally, it features protective shielding to reduce electromagnetic interference, ensuring reliable signal transmission 3.

Benefits of Using the 3641610 Wiring Harness

Utilizing the 3641610 Wiring Harness offers several advantages. It enhances the reliability of the truck’s electrical system by providing secure and durable connections. The harness also contributes to improved efficiency, as it allows the ECM to monitor and adjust various systems in real-time. Furthermore, its design ensures seamless integration with modern truck systems, facilitating easier upgrades and maintenance.

Installation and Integration

Proper installation of the 3641610 Wiring Harness is vital to ensure compatibility and optimal performance. It should be installed according to the manufacturer’s guidelines, with careful attention to routing and securing the harness to prevent damage from vibrations or abrasion. Ensuring that all connections are secure and properly grounded is also critical to avoid electrical issues.

Troubleshooting Common Issues

Common problems with the 3641610 Wiring Harness may include loose connections, damaged wires, or corrosion. Troubleshooting steps involve inspecting the harness for visible damage, ensuring all connections are secure, and checking for signs of corrosion. If issues are detected, repairing or replacing the affected sections of the harness may be necessary to restore proper function.

Maintenance Tips

Routine maintenance of the 3641610 Wiring Harness is important to ensure its longevity and reliable operation. This includes regular inspection for signs of wear or damage, cleaning any corrosion from connectors, and ensuring that all connections remain secure. Following the manufacturer’s recommended maintenance schedule will help prevent issues and ensure the harness continues to perform effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to producing high-quality components. The company’s extensive experience and dedication to innovation are reflected in products like the 3641610 Wiring Harness, which are designed to meet the demanding requirements of commercial trucking.

Conclusion

The Cummins 3641610 Electronic Control Module Wiring Harness is a critical component for the integration and operation of the ECM within commercial trucks. Its robust design, high-quality materials, and precise engineering ensure reliable performance and durability, making it a cornerstone of the truck’s electronic control system.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels, Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.