This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

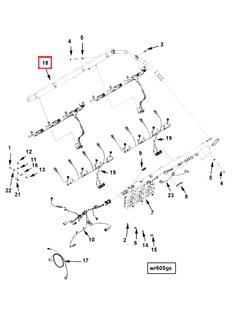

The Cummins 3642412 Electronic Control Module (ECM) Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates communication between the ECM and various sensors, actuators, and other electronic components within the vehicle. This harness ensures that the ECM receives accurate data and can effectively control the truck’s operations, contributing to overall performance and efficiency.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors designed to link the ECM to the truck’s various electronic components. It consists of multiple wires, each serving a specific function, bundled together for organized routing and protection. The harness allows the ECM to monitor and control engine functions, transmission operations, and other critical systems by transmitting data and power signals 1.

Role of the 3642412 Electronic Control Module Wiring Harness in Truck Operation

The 3642412 Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to interact with other systems and components. It ensures that the ECM receives real-time data from sensors, which it uses to make adjustments to engine performance, fuel efficiency, and emissions. Additionally, the harness allows the ECM to send commands to actuators and other control units, ensuring that the truck operates smoothly and efficiently 2.

Key Features of the 3642412 Electronic Control Module Wiring Harness

The 3642412 Electronic Control Module Wiring Harness is designed with several key features to enhance its performance and durability. It utilizes high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to meet stringent industry standards, ensuring reliable operation in demanding conditions. Technological advancements such as improved insulation and robust connectors contribute to its effectiveness and longevity 3.

Benefits of Using the 3642412 Electronic Control Module Wiring Harness

Using the 3642412 Electronic Control Module Wiring Harness offers several benefits. It enhances the efficiency of the truck’s electrical system by providing a reliable connection between the ECM and other components. This results in improved engine performance, better fuel economy, and reduced emissions. The harness also contributes to the overall reliability of the truck, minimizing the risk of electrical failures and ensuring consistent operation 4.

Installation and Integration

When installing and integrating the 3642412 Electronic Control Module Wiring Harness into a truck’s electrical system, it is important to follow manufacturer guidelines to ensure proper fitment and function. This includes routing the harness correctly to avoid interference with other components and securing it in place to prevent damage from vibration or movement. Careful attention to detail during installation helps maintain the integrity of the electrical system and ensures optimal performance.

Troubleshooting Common Issues

Troubleshooting common issues with the 3642412 Electronic Control Module Wiring Harness involves identifying and addressing problems such as loose connections, damaged wires, or faulty sensors. Diagnostic procedures may include visual inspections, testing electrical continuity, and using diagnostic tools to pinpoint issues. Potential solutions range from repairing or replacing damaged sections of the harness to recalibrating sensors or reprogramming the ECM.

Maintenance and Care

Regular maintenance and care of the 3642412 Electronic Control Module Wiring Harness are important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the harness to remove dirt and debris. Proper maintenance helps prevent issues and ensures that the harness continues to function effectively within the truck’s electrical system.

Safety Considerations

When working with the 3642412 Electronic Control Module Wiring Harness, it is important to observe safety precautions to protect both the technician and the equipment. This includes disconnecting the battery before beginning any work to prevent electrical shocks, using appropriate tools and personal protective equipment, and following manufacturer guidelines for handling and installation. Adhering to best practices ensures a safe working environment and maintains the integrity of the electrical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s commitment to innovation and quality has made it a preferred choice for commercial vehicle manufacturers and operators worldwide.

Electronic Control Module Wiring Harness (Part 3642412) in Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, identified by the part number 3642412, is a critical component in the Cummins QSK50, CM2150, and MCRS engines. This wiring harness is designed to facilitate the connection between the ECM and various sensors, actuators, and other electronic components within the engine system.

For the QSK50 engine, the ECM Wiring Harness ensures seamless communication between the ECM and the engine’s electronic control units, enabling precise management of engine performance, fuel injection, and emissions control. This harness is engineered to withstand the demanding conditions of heavy-duty applications, providing reliable and robust connectivity.

In the CM2150 engine, the ECM Wiring Harness plays a pivotal role in integrating the ECM with the engine’s electronic systems. It ensures that the ECM can effectively monitor and control engine parameters, enhancing overall efficiency and performance. The harness is designed to meet the stringent requirements of marine applications, offering durability and resistance to environmental factors.

For the MCRS engine, the ECM Wiring Harness is equally essential. It connects the ECM to the engine’s various electronic components, ensuring that the ECM can accurately manage engine functions. This harness is built to endure the rigorous demands of military and defense applications, providing dependable performance under extreme conditions.

Overall, the ECM Wiring Harness (Part 3642412) is a vital component for the Cummins QSK50, CM2150, and MCRS engines, ensuring that the ECM can effectively communicate with and control the engine’s electronic systems.

Understanding the Role of Part 3642412 Electronic Control Module Wiring Harness in Engine Systems

The part 3642412 Electronic Control Module (ECM) Wiring Harness is an integral component in modern engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This wiring harness is meticulously designed to ensure reliable and efficient operation of the engine by connecting the ECM to essential systems such as the fuel injection system, ignition system, and emission control system.

Fuel Injection System Integration

In fuel-injected engines, the ECM Wiring Harness plays a significant role by connecting the ECM to fuel injectors. This connection allows the ECM to precisely control the amount of fuel delivered to the combustion chamber, optimizing fuel efficiency and performance. The harness also interfaces with fuel pressure sensors and fuel temperature sensors, providing the ECM with real-time data to make accurate fuel delivery adjustments.

Ignition System Coordination

For ignition systems, the ECM Wiring Harness ensures that the ECM can communicate with ignition coils and spark plugs. This enables the ECM to control the timing and intensity of the spark, which is vital for efficient combustion. The harness also connects to crankshaft and camshaft position sensors, allowing the ECM to monitor engine speed and position, ensuring that the spark is delivered at the optimal moment.

Emission Control System Management

In terms of emission control, the ECM Wiring Harness connects the ECM to oxygen sensors, exhaust gas recirculation (EGR) valves, and catalytic converters. This allows the ECM to monitor and adjust the air-fuel mixture to minimize harmful emissions. The harness also facilitates communication with other emission-related sensors and actuators, ensuring that the engine complies with environmental regulations.

Additional System Interactions

Beyond the primary systems, the ECM Wiring Harness also interfaces with other components such as the mass airflow sensor, throttle position sensor, and various engine temperature sensors. These connections enable the ECM to gather comprehensive data about engine conditions, allowing it to make informed decisions to enhance performance, fuel efficiency, and durability.

In summary, the part 3642412 ECM Wiring Harness is a fundamental component that ensures the ECM can effectively manage and optimize the operation of various engine systems. Its robust design and precise engineering contribute to the overall reliability and performance of the engine.

Conclusion

The 3642412 Electronic Control Module Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring reliable communication between the ECM and various engine components. Its role in enhancing engine performance, fuel efficiency, and emissions control makes it indispensable for modern engine systems. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.