3642495

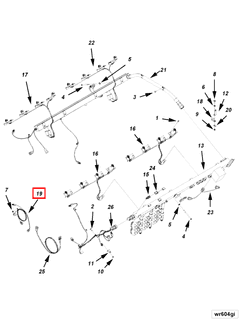

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3642495 Electronic Control Module Wiring Harness by Cummins is a specialized component designed to facilitate the electrical connections within commercial trucks. Its purpose is to ensure reliable communication between the electronic control module (ECM) and various sensors, actuators, and other electronic components throughout the vehicle. This harness plays a significant role in the operation of commercial trucks by providing a structured and organized pathway for electrical signals, thereby contributing to the overall efficiency and performance of the truck 3.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires, connectors, and terminals that are bundled together to manage the electrical connections in a vehicle’s system. The components of a wiring harness include insulated wires, connectors, terminals, and sometimes protective coverings. The harness functions by routing electrical signals from the ECM to various parts of the truck, ensuring that all electronic components operate in unison. This system is integral to the truck’s electrical architecture, allowing for precise control and monitoring of engine functions, transmission operations, and other critical systems 1.

Role of the 3642495 Electronic Control Module Wiring Harness in Truck Operation

The 3642495 Wiring Harness plays a specific role in the overall operation of a commercial truck by providing the necessary electrical connections for the ECM to communicate with other systems and components. It interacts with the engine control unit (ECU), transmission, sensors, and diagnostic tools, ensuring that data is accurately transmitted and received. This interaction is vital for the truck’s performance, as it allows for real-time monitoring and adjustment of various parameters, such as fuel injection, ignition timing, and emissions control 2.

Key Features of the 3642495 Wiring Harness

The 3642495 Wiring Harness is designed with several key features that enhance its functionality and reliability. These features include durability, which ensures the harness can withstand the harsh conditions often encountered in commercial trucking. The design of the harness is tailored to fit seamlessly within the truck’s electrical system, reducing the risk of errors during installation. Additionally, the harness offers integration capabilities, allowing it to connect with various truck systems and components without requiring extensive modifications.

Benefits of Using the 3642495 Wiring Harness

Using the 3642495 Wiring Harness offers several benefits, including improved reliability due to its robust construction and precise engineering. The harness contributes to the efficiency of the truck by ensuring that electrical signals are transmitted accurately and quickly. Furthermore, the design of the harness facilitates ease of maintenance, as it is structured to allow for straightforward access to individual wires and connectors, making repairs and replacements more manageable.

Troubleshooting the 3642495 Wiring Harness

When troubleshooting the 3642495 Wiring Harness, it is important to follow a systematic approach. Begin by identifying the symptoms of the issue, such as erratic sensor readings or failure of certain components to operate. Next, perform a visual inspection of the harness for any signs of damage, such as frayed wires or corroded connectors. If no visible issues are found, use diagnostic tools to test the electrical connections and identify any faults. Potential solutions may include repairing or replacing damaged sections of the harness or addressing issues with connected components.

Maintenance Tips for the 3642495 Wiring Harness

To ensure the longevity and optimal performance of the 3642495 Wiring Harness, regular maintenance is recommended. This includes conducting periodic inspections for signs of wear or damage, cleaning connectors to prevent corrosion, and ensuring that all connections are secure. Additionally, protecting the harness from physical damage and environmental factors, such as moisture and extreme temperatures, can help maintain its integrity. Following these maintenance practices can contribute to the reliable operation of the truck’s electrical system.

Integration with Other Systems

The 3642495 Wiring Harness integrates with various truck systems, including the engine control unit (ECU), transmission, and diagnostic tools. This integration allows for seamless communication between the ECM and other components, enabling precise control and monitoring of the truck’s operations. The harness is designed to connect with these systems using standardized connectors and terminals, ensuring compatibility and ease of installation.

Common Applications

The 3642495 Wiring Harness is commonly used in various types of commercial trucks and heavy-duty vehicles. Its applications include integration with diesel engines, automated transmissions, and advanced diagnostic systems. The harness is versatile and can be adapted to fit a wide range of truck models, making it a popular choice for fleet operators and maintenance professionals.

Safety Considerations

When installing, maintaining, or troubleshooting the 3642495 Wiring Harness, it is important to consider safety. Ensure that the truck’s electrical system is de-energized before beginning any work to prevent electrical shocks. Use appropriate personal protective equipment (PPE) and follow all manufacturer guidelines and industry best practices. Additionally, be mindful of the potential for sharp edges or hot components near the wiring harness, and take steps to avoid injury.

About Cummins

Cummins is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s product range includes solutions for on-highway and off-highway applications, providing reliable and efficient power for a variety of industries. Cummins’ dedication to research and development ensures that its products meet the evolving needs of customers and contribute to the advancement of the automotive sector 3.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 3642495, is a critical component for the proper functioning of Cummins engines. This wiring harness is designed to ensure seamless communication between the ECM and various engine sensors and actuators. It is essential for the efficient operation of the engine’s electronic control systems.

Compatibility with Cummins Engines

The ECM Wiring Harness is compatible with several Cummins engine models, including:

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

These engines are part of the Cummins QSK series, known for their robust performance and reliability in various applications, from industrial to marine and power generation.

Installation and Functionality

When installed, the ECM Wiring Harness connects the ECM to the engine’s sensors, actuators, and other electronic components. This connection is vital for the ECM to monitor and control engine performance, ensuring optimal operation and efficiency. The harness is designed to withstand the harsh conditions typically found in industrial and marine environments, providing durability and reliability.

Importance of the Wiring Harness

The ECM Wiring Harness plays a crucial role in the overall health and performance of the engine. It ensures that the ECM can accurately receive data from various sensors, such as temperature, pressure, and speed sensors. This data is then used by the ECM to make real-time adjustments to the engine’s operation, enhancing performance and fuel efficiency.

Moreover, the wiring harness is designed to minimize electrical interference, which can cause errors in the ECM’s readings and lead to suboptimal engine performance. By providing a secure and reliable connection, the ECM Wiring Harness helps maintain the integrity of the engine’s electronic systems.

Maintenance and Replacement

Regular inspection and maintenance of the ECM Wiring Harness are essential to ensure its proper functioning. Over time, wear and tear, as well as exposure to environmental factors, can cause the harness to degrade. Any signs of damage, such as frayed wires or loose connections, should be addressed promptly to prevent potential engine issues.

When replacing the ECM Wiring Harness, it is important to use genuine Cummins parts to maintain the engine’s performance and reliability. Using non-genuine parts can lead to compatibility issues and may compromise the engine’s electronic systems.

Role of Part 3642495 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module Wiring Harness (Part 3642495) serves as the vital link between the Electronic Control Module (ECM) and various engine components, ensuring seamless communication and operation. This harness is integral to the efficient functioning of the engine system, facilitating the transfer of data and power between the ECM and other critical parts.

Integration with Engine Components

-

Fuel System: The harness connects the ECM to the fuel injectors, fuel pump, and fuel pressure sensor. This connection allows the ECM to monitor and control fuel delivery, ensuring optimal combustion and performance.

-

Air Intake System: By linking the ECM to the Mass Air Flow (MAF) sensor and the Throttle Position Sensor (TPS), the harness enables precise air-fuel ratio management. This ensures that the engine receives the correct amount of air for efficient combustion.

-

Exhaust System: The harness interfaces with the Oxygen (O2) sensors located in the exhaust stream. These sensors provide feedback to the ECM on the exhaust gas composition, allowing for adjustments to the air-fuel mixture to minimize emissions and enhance performance.

-

Ignition System: Connections to the ignition coils and spark plugs are facilitated by the harness. This allows the ECM to control the timing and duration of the spark, optimizing ignition for different engine conditions.

-

Cooling System: The harness also connects the ECM to the Engine Coolant Temperature (ECT) sensor. This sensor provides data on the engine’s temperature, enabling the ECM to manage the cooling system and prevent overheating.

-

Emission Control System: Integration with components like the Evaporative Emission Control (EVAP) system and the Exhaust Gas Recirculation (EGR) valve is achieved through the harness. This ensures that emissions are kept within regulatory limits while maintaining engine efficiency.

Enhanced Engine Performance and Reliability

The Electronic Control Module Wiring Harness (Part 3642495) plays a significant role in enhancing engine performance and reliability. By providing a robust and reliable connection between the ECM and various engine components, it ensures that the engine operates smoothly under a wide range of conditions. This not only improves overall performance but also contributes to the longevity of the engine by allowing for precise control and monitoring of critical parameters.

Conclusion

The 3642495 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks and Cummins engines. Its role in facilitating communication between the ECM and various engine components ensures the efficient and reliable operation of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to enhanced engine performance and longevity.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.