This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

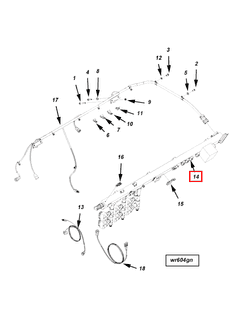

The Electronic Control Module (ECM) Wiring Harness, part number 3643640, is a critical component in the electrical systems of various Cummins engines. Manufactured by Cummins Inc., a leader in the commercial truck industry, this part exemplifies the company’s commitment to quality and innovation in vehicle electronics.

Basic Concepts

ECM Wiring Harnesses are foundational to modern vehicle electronics and communication systems. They serve as the conduit through which various electronic components communicate and operate in unison. These harnesses are designed to handle the complex web of signals and data that flow between different parts of a vehicle’s electronic system, ensuring seamless operation and communication 1.

Purpose and Functionality

The ECM Wiring Harness part 3643640 plays a significant role in the operation of Cummins engines. It is responsible for connecting various electronic components, such as sensors, actuators, and the ECM, facilitating communication and data exchange between them. This connectivity is essential for the ECM to monitor and control engine functions, optimize performance, and ensure efficient operation of the engine 2.

Key Features

The ECM Wiring Harness part 3643640 is characterized by its robust design and high-quality construction materials. It is engineered to withstand the demanding conditions of commercial truck operations, including exposure to vibrations, temperature fluctuations, and electrical stress. Its design incorporates features that enhance its performance and reliability, such as corrosion-resistant materials and durable connectors 3.

Benefits

The integration of the ECM Wiring Harness part 3643640 into an engine’s system offers several benefits. It contributes to improved engine performance by ensuring precise communication between the ECM and other electronic components. This precise communication leads to enhanced fuel efficiency, as the ECM can make real-time adjustments to engine parameters. Additionally, the harness’s reliability ensures consistent operation, reducing the likelihood of electronic failures and contributing to the overall reliability of the engine.

Troubleshooting and Maintenance

To maintain the optimal performance of the ECM Wiring Harness part 3643640, regular inspections and maintenance are recommended. Common issues may include worn connectors, damaged wires, or corrosion. Addressing these issues promptly can prevent more significant problems and ensure the harness continues to function effectively. Maintenance tips include keeping the harness clean, checking for signs of wear or damage, and ensuring all connections are secure.

Integration with Cummins Systems

The ECM Wiring Harness part 3643640 is designed to integrate seamlessly with Cummins engine systems and other components. Its compatibility with Cummins-powered engines ensures that it operates efficiently within the vehicle’s electronic architecture. This integration allows for optimized performance and communication between the ECM and other electronic components, contributing to the overall efficiency and reliability of Cummins-powered engines.

Manufacturer Overview - Cummins

Cummins Inc. is a global leader in the commercial truck industry, known for its high-quality engines, components, and technologies. With a rich history of innovation and a diverse product portfolio, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is evident in its product offerings, including the ECM Wiring Harness part 3643640, which embodies Cummins’ dedication to advancing vehicle technology and enhancing the operational efficiency of commercial trucks.

Conclusion

The ECM Wiring Harness part 3643640 is a vital component in the electrical systems of Cummins engines, ensuring seamless communication and control between the ECM and various engine components. Its robust design, high-quality construction, and integration with Cummins systems contribute to improved engine performance, enhanced fuel efficiency, and overall reliability. Regular maintenance and prompt troubleshooting are essential to ensure the continued optimal performance of this critical component.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.