This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

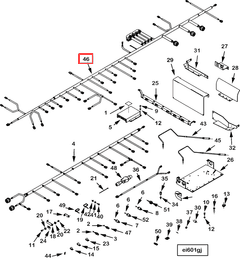

The Cummins Electronic Control Module Wiring Harness (Part #3644539) is a critical component in the operation of heavy-duty trucks. This wiring harness facilitates communication and power distribution between the Electronic Control Module (ECM) and various truck components. Manufactured by Cummins, a reputable name in the automotive industry, this part ensures reliable and efficient performance of the truck’s engine and related systems 1.

Basic Concepts

The ECM serves as the brain of the truck’s engine management system, responsible for monitoring and controlling various engine functions. The wiring harness provides the necessary electrical connections that enable the ECM to communicate with sensors, actuators, and other components. It also distributes power to these components, ensuring they operate correctly. This Cummins part is specifically engineered to meet the demanding requirements of heavy-duty applications 2.

Purpose and Functionality

The 3644539 Electronic Control Module Wiring Harness is designed to enable the ECM to effectively monitor and control engine performance, emissions, and other critical functions. By providing a robust and reliable electrical connection, the wiring harness ensures that the ECM receives accurate data from sensors and can send control signals to actuators. This facilitates precise management of fuel injection, ignition timing, and emissions control, contributing to optimal engine performance and efficiency 3.

Key Features

The 3644539 Wiring Harness is characterized by several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to the harsh conditions typically encountered in heavy-duty truck applications. The design includes robust connectors and terminals that ensure secure and reliable electrical connections. Additionally, the harness is protected by durable insulation and shielding to prevent damage from vibration, moisture, and electromagnetic interference 4.

Benefits

Using the 3644539 Wiring Harness offers several benefits. It contributes to improved engine efficiency by ensuring that the ECM receives accurate data and can make precise adjustments to engine parameters. The harness also enhances diagnostic capabilities, allowing for more effective troubleshooting of engine issues. Furthermore, its durable construction and reliable performance increase the overall reliability of the truck’s engine management system 5.

Installation and Compatibility

Proper installation of the 3644539 Wiring Harness is important to ensure its effective performance. It is designed to be compatible with various Cummins engines and truck models, though specific installation requirements may vary. It is important to follow the manufacturer’s guidelines to ensure that all connections are secure and that the harness is properly routed to avoid damage from heat, friction, or moving parts 6.

Troubleshooting and Maintenance

To troubleshoot common issues related to the 3644539 Wiring Harness, it is important to inspect the harness for signs of damage, such as frayed wires, corroded connectors, or loose terminals. Regular maintenance, including cleaning connectors and checking for secure connections, can help ensure the longevity and optimal performance of the wiring harness. If issues persist, consulting the manufacturer’s diagnostic guidelines can provide further insight 7.

Safety Considerations

When working with the 3644539 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring that the truck’s battery is disconnected before beginning any work on the harness to prevent the risk of electrical shock or short circuits. Additionally, taking precautions to avoid damage to the harness, such as protecting it from sharp edges and moving parts, is important to maintain its integrity and performance 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly for its diesel engines and related components. The company is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the production of heavy-duty truck parts 9.

Application in Cummins Engines

K50 Series Engines

The K50 series engines, known for their robust performance and reliability, integrate the 3644539 wiring harness to facilitate efficient data transfer and control. This harness is meticulously engineered to withstand the demanding conditions of heavy-duty operations, ensuring that the ECM can effectively manage engine functions such as fuel injection, ignition timing, and emissions control.

Grouped Applications

In the broader context of Cummins engine applications, the 3644539 wiring harness is not limited to the K50 series alone. It is also compatible with a range of other Cummins engines that share similar electrical architecture and ECM configurations. This compatibility allows for easier maintenance and repair, as technicians can use a standardized wiring harness across multiple engine models.

The design of the 3644539 wiring harness prioritizes durability and precision. It is constructed with high-quality materials that resist wear and tear, ensuring a long service life even under harsh operating conditions. Additionally, the harness is engineered to minimize electrical resistance and interference, which is crucial for maintaining optimal engine performance and reliability.

By integrating the 3644539 wiring harness into their engine systems, Cummins ensures that the ECM can perform its critical functions without interruption, thereby enhancing the overall efficiency and dependability of the engine.

Role of Part 3644539 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3644539, is an integral component in the orchestration of modern engine systems. This wiring harness serves as the vital link between the ECM and various engine components, facilitating seamless communication and control.

Integration with the Monitor

The ECM Wiring Harness interfaces directly with the engine monitor, a device responsible for real-time data acquisition and display of engine performance metrics. Through this harness, the ECM transmits commands and receives feedback from the monitor, enabling precise adjustments to engine parameters such as fuel injection timing, ignition timing, and air-fuel ratio. This continuous data exchange ensures optimal engine performance and efficiency.

Connection to the Electronic Engine

In the context of an electronic engine, the ECM Wiring Harness plays a pivotal role in managing the complex interactions between the ECM and the engine’s electronic components. It provides the necessary electrical connections to sensors, actuators, and other control units distributed throughout the engine. For instance, the harness connects the ECM to oxygen sensors, throttle position sensors, and various solenoids, allowing the ECM to monitor and adjust engine operations dynamically. This integration is essential for maintaining engine health, enhancing performance, and ensuring compliance with emissions regulations.

The ECM Wiring Harness is designed to withstand the harsh environment within an engine compartment, including exposure to heat, vibration, and chemical agents. Its robust construction and precise engineering ensure reliable operation and longevity, contributing to the overall durability and performance of the engine system.

Conclusion

The Cummins Electronic Control Module Wiring Harness (Part #3644539) is a vital component in the operation of heavy-duty trucks, ensuring reliable and efficient performance of the engine and related systems. Its robust design, durable construction, and precise engineering make it an essential part of modern engine management systems.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5411106, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5411106, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5411106, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5411106, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5411106, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.