This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

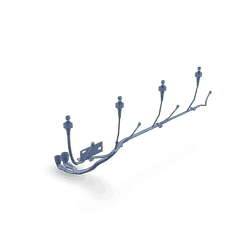

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3645548, is a vital component in the operation of heavy-duty trucks. Manufactured by Cummins, a leader in the automotive industry, this wiring harness is designed to facilitate the communication and operation of various electronic components within the vehicle.

Basic Concepts

ECM Wiring Harnesses serve as the backbone of a vehicle’s electronic system. They enable the transmission of data and power between the ECM and other electronic components. This communication is essential for the operation of the vehicle’s systems, including engine management, transmission control, and various auxiliary functions 1.

Purpose and Functionality

The 3645548 ECM Wiring Harness plays a significant role in the operation of a truck by connecting various electronic components and facilitating communication between them. It ensures that the ECM can effectively manage and control the engine and other systems, optimizing performance and efficiency.

Key Features

The 3645548 ECM Wiring Harness is characterized by its robust design and high-quality construction materials. It is engineered to withstand the harsh conditions often encountered in heavy-duty truck applications. Unique characteristics of this wiring harness include its durable connectors, corrosion-resistant materials, and precise engineering, which enhance its performance and reliability 2.

Benefits

The use of the 3645548 ECM Wiring Harness offers several benefits. It contributes to improved engine performance by ensuring efficient communication between the ECM and other components. Additionally, it enhances fuel efficiency and increases the reliability of the truck’s electronic systems, even in demanding operating conditions 3.

Troubleshooting and Maintenance

Common issues with the 3645548 ECM Wiring Harness may include connector corrosion, wire damage, or faulty connections. Troubleshooting steps involve inspecting the harness for visible damage, ensuring all connections are secure, and testing for proper electrical continuity. Routine maintenance includes keeping the harness clean and dry, inspecting for wear or damage, and addressing any issues promptly to ensure optimal performance and longevity.

Integration with Cummins Engines

The 3645548 ECM Wiring Harness is designed for seamless integration with Cummins engines. It is compatible with a range of Cummins engine models and is engineered to meet the specific requirements of these applications. Installation procedures are straightforward, with detailed instructions provided to ensure proper setup. Specific considerations for Cummins engine applications include ensuring correct alignment and secure connections to maintain the integrity of the engine’s electronic system.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the automotive industry, Cummins is known for its high-quality products and innovative solutions. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in heavy-duty truck components.

Role of Part 3645548 ECM Wiring Harness in Engine Systems

The ECM Wiring Harness, identified by part number 3645548, is integral to the operation of modern engine systems. This component serves as the vital link between the ECM and various engine sensors, actuators, and other control units.

Integration with Engine Sensors

The ECM Wiring Harness facilitates communication between the ECM and a multitude of engine sensors. These sensors include the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, Oxygen (O2) sensors, and others. By providing a robust and reliable connection, the harness ensures that the ECM receives accurate and timely data from these sensors, enabling precise control over fuel injection, ignition timing, and emissions.

Connection to Actuators

Actuators such as the fuel injectors, throttle body, and variable valve timing (VVT) solenoids rely on the ECM Wiring Harness to receive commands from the ECM. This connection allows for dynamic adjustments to engine performance based on driving conditions and sensor inputs. The harness ensures that these actuators operate in harmony with the ECM’s directives, optimizing engine efficiency and responsiveness.

Interface with Other Control Units

In complex engine systems, the ECM often communicates with other control units such as the Transmission Control Module (TCM) and Anti-lock Braking System (ABS) module. The ECM Wiring Harness plays a key role in these interactions, providing the necessary pathways for data exchange. This integration enhances overall vehicle performance by allowing different systems to work cohesively.

Support for Diagnostic Functions

The ECM Wiring Harness is also essential for onboard diagnostics. It allows the ECM to monitor the health of various engine components and systems. Through the harness, the ECM can detect issues such as sensor malfunctions, actuator failures, or wiring problems, enabling timely maintenance and repairs.

Enhancement of Safety Features

Modern engine systems incorporate various safety features, such as engine immobilizers and crash sensors. The ECM Wiring Harness supports these features by ensuring that the ECM can communicate with and control these safety-critical components effectively. This enhances vehicle safety by enabling rapid responses to potential threats.

Conclusion

In summary, the ECM Wiring Harness (part 3645548) is a foundational component in engine systems, facilitating essential connections between the ECM and a wide array of sensors, actuators, and control units. Its role in data transmission, system integration, and diagnostic capabilities underscores its importance in maintaining optimal engine performance and vehicle safety.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.