This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

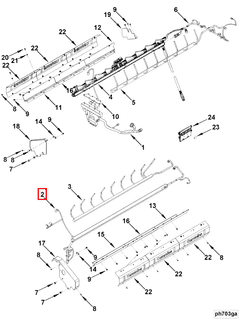

The Electronic Control Module Wiring Harness (Part #3647881) by Cummins is a vital component in the operation of heavy-duty trucks. Cummins, a well-established manufacturer in the automotive industry, produces this wiring harness to ensure efficient and reliable communication between the Electronic Control Module (ECM) and various truck systems. This component plays a significant role in the overall performance and functionality of heavy-duty vehicles 1.

Basic Concepts

The Electronic Control Module (ECM) is the brain of the truck, managing and regulating numerous operations such as fuel injection, engine timing, and emissions control. The wiring harness serves as the nervous system, connecting the ECM to sensors, actuators, and other critical components throughout the vehicle. It facilitates the transmission of data and power, ensuring that all systems operate in harmony 2.

Purpose of the 3647881 Electronic Control Module Wiring Harness

The 3647881 Electronic Control Module Wiring Harness is designed to enhance the operation of a truck by providing a robust and reliable connection between the ECM and other truck systems. It enables seamless communication, allowing the ECM to monitor and adjust various parameters in real-time. This ensures optimal performance, efficiency, and safety of the vehicle 3.

Key Features

The 3647881 Electronic Control Module Wiring Harness boasts several key features that contribute to its performance and durability. Its design incorporates high-quality materials resistant to wear, corrosion, and environmental factors. The harness is engineered to withstand the rigors of heavy-duty truck operations, ensuring long-lasting reliability. Additionally, it features organized wiring and secure connections to minimize the risk of faults and improve overall system integrity.

Benefits

Utilizing the 3647881 Electronic Control Module Wiring Harness offers several advantages. It enhances the reliability of the truck’s electronic systems, leading to improved performance and efficiency. The harness simplifies maintenance by providing easy access to connections and reducing the likelihood of wiring issues. Furthermore, its robust construction contributes to the longevity of the truck’s electronic components.

Installation Process

Installing the 3647881 Electronic Control Module Wiring Harness requires careful attention to detail. Begin by ensuring the truck’s electrical system is disconnected to avoid any risk of electrical shock. Follow the manufacturer’s instructions for routing the harness through the vehicle, securing it in place, and connecting it to the ECM and other components. Use the appropriate tools to ensure secure and proper connections.

Common Issues and Troubleshooting

Common issues with the 3647881 Electronic Control Module Wiring Harness may include loose connections, damaged wires, or ECM communication failures. To troubleshoot, inspect the harness for any visible signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If communication issues persist, use diagnostic tools to identify specific faults within the system.

Maintenance Tips

To ensure the longevity and optimal performance of the 3647881 Electronic Control Module Wiring Harness, regular maintenance is recommended. Perform routine checks to ensure all connections are secure and free from corrosion. Inspect the harness for any signs of wear or damage, and address any issues promptly to prevent further complications. Keeping the harness clean and organized will also contribute to its reliability.

Safety Considerations

When working with the 3647881 Electronic Control Module Wiring Harness, it is important to follow safety guidelines to avoid electrical hazards and ensure personal safety. Always disconnect the truck’s electrical system before beginning any work on the harness. Use insulated tools and wear appropriate personal protective equipment (PPE) to protect against electrical shocks. Be mindful of your surroundings and avoid working in wet or damp conditions.

Cummins Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry, particularly in the production of components for heavy-duty trucks. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ products, including the 3647881 Electronic Control Module Wiring Harness, are designed to meet the demanding requirements of heavy-duty applications, ensuring reliable performance and durability.

Role of Part 3647881 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified as part 3647881, serves as the vital connective tissue within engine systems, facilitating seamless communication and power distribution between various components. This harness is meticulously designed to interface with the ECM, ensuring that all electrical signals are accurately transmitted and received.

Integration with Key Components

-

Engine Control Module (ECM): The ECM Wiring Harness is directly connected to the ECM, allowing it to receive and process data from various sensors and actuators. This connection ensures that the ECM can effectively manage engine operations, including fuel injection, ignition timing, and emissions control.

-

Wiring Assembly Harness: This harness works in conjunction with the main wiring assembly harness, which routes power and signals to and from the ECM. It ensures that all subsystems within the engine are interconnected, enabling the ECM to monitor and adjust engine performance in real-time.

-

Sensors and Actuators: The ECM Wiring Harness links numerous sensors (such as the oxygen sensor, throttle position sensor, and mass airflow sensor) and actuators (like the fuel injectors and ignition coils) to the ECM. This allows for precise control and feedback, optimizing engine efficiency and performance.

-

Power Distribution: By providing a structured pathway for electrical current, the ECM Wiring Harness ensures that power is efficiently distributed to all necessary components. This includes the ignition system, fuel system, and ancillary systems like the starter motor and alternator.

-

Diagnostic Capabilities: The harness also plays a role in onboard diagnostics by allowing the ECM to communicate with diagnostic tools. This facilitates the identification of issues and ensures that the engine system can be maintained and repaired effectively.

Conclusion

In summary, the ECM Wiring Harness (part 3647881) is an indispensable component that ensures the engine system operates cohesively and efficiently. Its role in connecting and powering various engine components underscores its importance in modern automotive engineering.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.