3648148

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3648148 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the commercial truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication and power distribution necessary for the truck’s electronic systems to function correctly.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link various electronic components within a truck’s electrical system. It serves as the conduit for signals and power between the Electronic Control Module (ECM) and other electronic systems. The harness typically includes insulated wires, connectors, and sometimes protective conduits to safeguard the wires from physical damage and environmental factors 1.

Purpose of the 3648148 Electronic Control Module Wiring Harness

The 3648148 Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to communicate with and control various electronic systems. It ensures that signals and power are accurately transmitted between the ECM and components such as sensors, actuators, and other control units. This interaction is vital for the truck’s performance, efficiency, and overall functionality 2.

Key Features

The 3648148 Wiring Harness is designed with several features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to fit precisely within the truck’s existing framework, ensuring a secure and reliable connection. Additionally, it may include features such as strain reliefs and protective conduits to further enhance its durability and longevity.

Benefits

The 3648148 Wiring Harness offers several benefits over other wiring solutions. Its design and construction contribute to improved reliability and efficiency in the truck’s electronic systems. The harness is also designed for ease of installation, with features that simplify the connection process and reduce the likelihood of errors during installation.

Installation Process

Installing the 3648148 Wiring Harness involves several steps to ensure a secure and reliable connection. Begin by identifying the correct location for the harness within the truck’s framework. Carefully route the wires to avoid sharp edges and moving parts, using any provided conduits or protective measures. Connect the harness to the ECM and other electronic components, ensuring that all connections are secure and correctly aligned. Finally, test the harness to confirm that all connections are functioning as intended.

Troubleshooting Common Issues

Common issues with the 3648148 Wiring Harness may include loose connections, damaged wires, or environmental factors affecting the harness’s performance. To troubleshoot these issues, begin by inspecting the harness for any visible damage or loose connections. If a problem is identified, carefully repair or replace the affected section, ensuring that all connections are secure and correctly aligned. Regular inspections can help identify potential issues before they become significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3648148 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for any signs of wear, damage, or loose connections. Cleaning the harness and its connections can also help prevent corrosion and other environmental factors from affecting its performance. Additionally, protecting the harness from physical damage and environmental factors can contribute to its durability and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, designed to meet the diverse needs of its customers.

Cummins Electronic Control Module Wiring Harness (Part 3648148)

The Cummins Electronic Control Module (ECM) Wiring Harness, identified by the part number 3648148, is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to ensure seamless communication and power distribution between the ECM and other electronic components within the engine system.

Application in Cummins Engines

QSK45 CM500

The QSK45 CM500 engine, known for its robust performance and reliability, integrates the ECM Wiring Harness to manage and control various engine functions. This harness facilitates the transfer of essential data and power, ensuring that the ECM can effectively monitor and adjust engine parameters such as fuel injection, ignition timing, and emissions control.

QSK50 Series

Similarly, the QSK50 Series engines, which are part of Cummins’ lineup of high-output, heavy-duty diesel engines, also utilize the 3648148 ECM Wiring Harness. This harness is crucial for maintaining the integrity of the engine’s electronic control system, ensuring that the ECM can communicate with other engine modules and sensors accurately.

QSK60 Series

The QSK60 Series engines, designed for demanding applications such as marine and power generation, also benefit from the ECM Wiring Harness. This component ensures that the ECM can effectively manage the engine’s performance and efficiency, providing the necessary data and power to the various electronic systems.

Importance of the ECM Wiring Harness

The ECM Wiring Harness is integral to the overall functionality of the engine’s electronic control system. It ensures that the ECM can receive and send data to other components, such as sensors and actuators, which are critical for the engine’s operation. This harness is designed to withstand the harsh conditions often encountered in heavy-duty applications, ensuring long-term reliability and performance.

By integrating the ECM Wiring Harness into the engine system, Cummins ensures that the ECM can effectively manage and optimize engine performance, contributing to the overall efficiency and reliability of the engine.

Role of Part 3648148 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 3648148, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of data and electrical signals necessary for engine management.

Integration with Engine Components

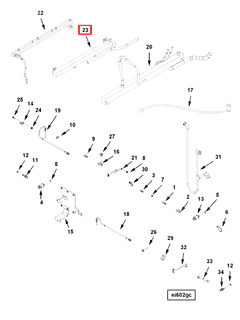

-

Harness: The ECM Wiring Harness is meticulously designed to interface with the main engine harness. This connection ensures seamless communication between the ECM and other electronic components within the engine system. It allows for the efficient transfer of sensor data to the ECM and the relaying of control signals from the ECM to actuators and other control devices.

-

Engine Monitoring Wiring: This harness is also responsible for connecting to the engine monitoring wiring. It plays a significant role in gathering data from various sensors distributed throughout the engine. These sensors monitor parameters such as temperature, pressure, and emissions. The harness transmits this data to the ECM, enabling it to make precise adjustments to engine operations for optimal performance and efficiency.

Functionality in Engine Systems

The ECM Wiring Harness is essential for the following functions within engine systems:

-

Data Acquisition: It collects real-time data from engine sensors, which is crucial for the ECM to assess engine conditions and performance.

-

Control Signal Distribution: It distributes control signals from the ECM to various actuators, such as fuel injectors, ignition coils, and variable valve timing systems, ensuring that the engine operates within specified parameters.

-

System Integration: By connecting disparate engine components, the harness ensures that all parts of the engine system work in unison, enhancing overall engine reliability and performance.

Conclusion

In summary, the ECM Wiring Harness (part 3648148) is a fundamental component in the orchestration of engine operations, ensuring that all electronic components within the engine system communicate effectively and function harmoniously. Its role in data acquisition, control signal distribution, and system integration is critical for the optimal performance and reliability of modern engine systems.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.