3648149

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Electronic Control Module Wiring Harness (Part #3648149) by Cummins is a vital component in the operation of commercial trucks. This wiring harness facilitates the communication between the Electronic Control Module (ECM) and various electronic components within the truck, ensuring efficient and reliable operation of the vehicle’s systems.

Basic Concepts of Electronic Control Module Wiring Harness

The Electronic Control Module Wiring Harness is designed to transmit electrical signals and power between the ECM and other electronic components in the truck. It consists of multiple wires, connectors, and protective housings that safeguard the integrity of the electrical connections. The harness integrates seamlessly within the truck’s electronic system, allowing for precise control and monitoring of engine functions, transmission operations, and other critical systems 1.

Role and Functionality

The Electronic Control Module Wiring Harness plays a significant role in the operation of a truck by enabling the ECM to communicate with sensors, actuators, and other electronic devices. This communication allows the ECM to gather data from various sources, process it, and send commands to control the truck’s systems. The harness ensures that these signals are transmitted accurately and efficiently, contributing to the overall performance and reliability of the vehicle 2.

Key Features

The Cummins Electronic Control Module Wiring Harness is characterized by its robust design and high build quality. It incorporates advanced technological features such as corrosion-resistant materials, durable connectors, and enhanced insulation to protect against environmental factors. These features contribute to the harness’s performance and reliability, ensuring it can withstand the demanding conditions of commercial truck operations.

Benefits

The Cummins Electronic Control Module Wiring Harness offers several advantages, including improved engine performance, enhanced fuel efficiency, and increased reliability of the truck’s electronic systems. By ensuring accurate and efficient communication between the ECM and other components, the harness helps optimize the truck’s operation, leading to better overall performance and reduced maintenance costs.

Installation and Compatibility

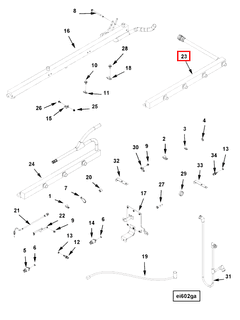

Proper installation of the Electronic Control Module Wiring Harness is crucial for its effective operation. It is designed to be compatible with various Cummins engines and can be integrated with existing truck electronic systems. Following the manufacturer’s guidelines during installation ensures that the harness functions correctly and contributes to the truck’s efficient operation.

Troubleshooting and Maintenance

To maintain the Electronic Control Module Wiring Harness’s longevity and optimal performance, regular inspections and maintenance are recommended. Common issues such as loose connections, damaged wires, or corroded connectors should be addressed promptly. Best practices for troubleshooting include checking for continuity, inspecting for physical damage, and ensuring all connections are secure.

Safety Considerations

When working with the Electronic Control Module Wiring Harness, it is important to adhere to safety protocols and electrical safety practices. This includes ensuring the truck’s battery is disconnected before beginning any work on the harness to prevent electrical shocks or short circuits. Additionally, taking precautions to avoid damage to the harness or connected components is crucial for maintaining the integrity of the truck’s electronic systems.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong reputation for producing high-quality automotive components. The company has a long history of innovation and excellence in the automotive industry, and its Electronic Control Module Wiring Harness is a testament to its commitment to quality and performance. Cummins continues to play a significant role in the development and production of advanced automotive components, ensuring the reliability and efficiency of commercial vehicles.

Electronic Control Module Wiring Harness for Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, part number 3648149, is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to ensure seamless communication between the ECM and other electronic control units (ECUs) within the engine system.

For the QSK60 engine, the ECM Wiring Harness plays a pivotal role in maintaining the integrity of the engine’s electronic control system. It ensures that the ECM can effectively manage engine performance, fuel injection, and emissions control by providing a reliable connection to the various sensors and actuators.

Similarly, for the CM500 engine, the ECM Wiring Harness is essential for the proper functioning of the engine’s electronic systems. It facilitates the transmission of critical data between the ECM and other components, ensuring that the engine operates efficiently and reliably.

Both the QSK60 and CM500 engines benefit from the robust design of the ECM Wiring Harness, which is engineered to withstand the rigors of heavy-duty applications. This harness is a key element in the overall reliability and performance of these engines, ensuring that they can deliver consistent power and efficiency in demanding environments.

Role of Part 3648149 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 3648149, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the communication and power distribution necessary for optimal engine performance.

Integration with Engine Monitoring Wiring

The ECM Wiring Harness is meticulously designed to interface with the engine monitoring wiring. This integration allows for the continuous transmission of data from sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors to the ECM. The harness ensures that the ECM receives accurate and timely information, enabling it to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

Connection to the Harness

The ECM Wiring Harness is also responsible for connecting to the main engine harness. This connection point is where the ECM Wiring Harness distributes power and signals to various actuators and components within the engine system. Components such as the fuel injectors, ignition coils, and variable valve timing (VVT) solenoids rely on the ECM Wiring Harness to receive the necessary commands from the ECM.

The harness also plays a role in grounding these components, ensuring that electrical signals are properly transmitted and received. This grounding is essential for the reliable operation of the engine’s electronic systems.

Ensuring System Integrity

By providing a robust and reliable connection between the ECM and the engine’s electronic components, the ECM Wiring Harness ensures the integrity of the engine’s control systems. It allows for the seamless integration of engine monitoring data with the ECM’s processing capabilities, leading to enhanced engine performance, efficiency, and reliability.

Conclusion

In summary, the Electronic Control Module Wiring Harness (Part #3648149) by Cummins is a fundamental component in the engine’s electronic system, enabling the ECM to effectively monitor and control various engine functions through its connections with the engine monitoring wiring and the main engine harness. Its robust design, advanced features, and seamless integration with engine systems contribute to the overall performance, efficiency, and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.