3649114

Electronic Control Module Wiring Harness

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

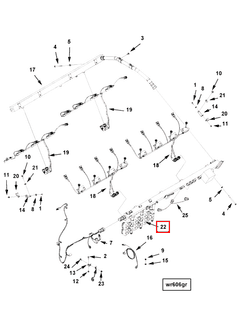

The Electronic Control Module Wiring Harness (Part #3649114) by Cummins is a vital component in the operation of commercial trucks. This wiring harness serves as the backbone for the electronic systems within the vehicle, facilitating communication between the Electronic Control Module (ECM) and various sensors, actuators, and other electronic components. Its role is significant in ensuring the efficient and reliable operation of the truck’s engine and ancillary systems 1.

Basic Concepts

Electronic Control Module Wiring Harnesses are integral to vehicle electronics, acting as the conduit through which data and control signals are transmitted. They enable seamless communication between the ECM and other electronic components, allowing for precise control and monitoring of the truck’s systems. In modern truck systems, these harnesses are crucial for maintaining optimal performance, efficiency, and reliability 2.

Purpose and Functionality

The 3649114 Electronic Control Module Wiring Harness is designed to connect the ECM to a wide array of sensors, actuators, and electronic components throughout the truck. This connection enables the transmission of data and control signals, allowing the ECM to monitor and adjust the operation of the engine and other systems in real-time. By facilitating this communication, the wiring harness plays a key role in the overall functionality and performance of the truck 3.

Key Features

The 3649114 Electronic Control Module Wiring Harness is characterized by its robust construction, high-quality materials, and precise engineering. These features ensure that the harness can withstand the demanding conditions of commercial truck operation, providing reliable performance and durability. Additionally, the harness is specifically designed for compatibility with Cummins engines, ensuring seamless integration and optimal functionality within the truck’s electronic system.

Benefits

The use of the 3649114 Electronic Control Module Wiring Harness offers several benefits, including improved engine performance, enhanced fuel efficiency, reduced emissions, and increased reliability. These advantages contribute to overall truck efficiency and profitability for fleet operators, making the harness a valuable component in the operation of commercial trucks.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are important for ensuring the optimal performance and longevity of the 3649114 Electronic Control Module Wiring Harness. Common issues such as electrical faults, connector corrosion, and wiring damage should be addressed promptly to prevent further complications. Performing regular maintenance checks and inspecting the wiring harness for signs of wear or damage can help identify potential problems early, allowing for timely repairs and replacements.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products, including engines, transmissions, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators. Cummins’ Electronic Control Module Wiring Harnesses, including the 3649114 model, reflect the company’s dedication to providing high-quality, reliable components that contribute to the efficient and profitable operation of commercial trucks.

Understanding the Integration of Part 3649114 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3649114, serves as a pivotal component in the orchestration of various engine systems. This harness is meticulously designed to facilitate seamless communication and power distribution between the ECM and an array of engine components.

Role in Engine Systems

-

Fuel Injection System: The ECM Wiring Harness is integral in relaying signals from the ECM to the fuel injectors. It ensures precise fuel delivery by transmitting data on engine load, throttle position, and other parameters essential for optimal combustion.

-

Ignition System: In coordination with the ECM, the harness manages the ignition timing by connecting to the ignition coils. It delivers the necessary signals for spark generation at the correct moment in the engine cycle.

-

Sensors and Actuators: The harness acts as a conduit for data flow between the ECM and various sensors (such as the Mass Air Flow sensor, Oxygen sensor, and Manifold Absolute Pressure sensor) and actuators (like the EGR valve and throttle body). This bidirectional communication is vital for real-time engine management.

-

Emission Control Systems: It plays a significant role in emission control by linking the ECM to components like the catalytic converter and the EVAP system. This connection ensures that the engine operates within environmental regulations.

-

Battery and Alternator: The harness is also responsible for managing the electrical supply from the battery and alternator to the ECM, ensuring consistent power for engine control functions.

-

CAN Bus Communication: In modern engine systems, the ECM Wiring Harness often interfaces with the Controller Area Network (CAN) bus, allowing for efficient data exchange between the ECM and other vehicle control modules.

Conclusion

In summary, the ECM Wiring Harness (part 3649114) is a fundamental component that ensures the ECM can effectively monitor and control the engine’s performance, efficiency, and emissions. Its role in connecting and powering various engine components underscores its importance in the overall engine management system.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.