3654717

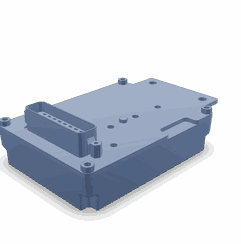

Electronic Control Module

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3654717 Electronic Control Module (ECM) is a sophisticated component designed to manage and optimize the operation of commercial trucks. This ECM is integral to the truck’s performance, ensuring efficient engine operation, precise emissions control, and comprehensive system monitoring. Its role in modern truck systems underscores the importance of advanced electronic management in enhancing vehicle efficiency and reliability 4.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized control unit that manages various functions within a vehicle’s system. It processes data from numerous sensors and actuators to regulate engine performance, transmission operations, and other critical systems. The ECM’s role is to interpret sensor data, make real-time adjustments, and ensure the vehicle operates within optimal parameters. In modern vehicles, the ECM is central to achieving enhanced performance, fuel efficiency, and emissions compliance 1.

Role of the Cummins 3654717 ECM in Truck Operation

The Cummins 3654717 ECM performs several key functions within a truck’s system. It manages engine operations by controlling fuel injection, ignition timing, and air-fuel ratio. The ECM also plays a role in emissions control by monitoring and adjusting engine parameters to meet regulatory standards. Additionally, it facilitates performance monitoring through diagnostic capabilities, allowing for the detection and reporting of system faults. The ECM ensures that the truck operates efficiently and reliably under varying conditions 2.

Key Features of the Cummins 3654717 ECM

The Cummins 3654717 ECM boasts several primary features that enhance its functionality. It is equipped with robust processing power to handle complex calculations and data processing in real-time. The ECM has a significant memory capacity, allowing it to store diagnostic data and system parameters. Its diagnostic capabilities enable it to identify and report faults, facilitating timely maintenance. Additionally, the ECM offers connectivity options for remote diagnostics and updates, ensuring it remains up-to-date with the latest software and performance enhancements 3.

Benefits of Using the Cummins 3654717 ECM

Incorporating the Cummins 3654717 ECM into truck systems offers several advantages. It contributes to improved fuel efficiency by optimizing engine performance and reducing unnecessary fuel consumption. The ECM enhances overall performance by ensuring the engine operates within optimal parameters. It also plays a role in better emissions control, helping the truck meet stringent regulatory standards. These benefits result in a more efficient, reliable, and environmentally friendly truck operation 4.

Troubleshooting and Maintenance Suggestions

Common issues with the Cummins 3654717 ECM may include diagnostic trouble codes, communication errors, or performance inconsistencies. Diagnostic procedures involve using specialized tools to retrieve and interpret fault codes, allowing for targeted repairs. Regular maintenance practices, such as updating the ECM’s software and performing routine checks on sensor and actuator functionality, help ensure optimal performance and longevity. Proactive monitoring and timely interventions are key to maintaining the ECM’s effectiveness 1.

Integration with Other Systems

The Cummins 3654717 ECM interacts with various other truck systems to provide a cohesive operational experience. It communicates with the transmission system to ensure smooth gear changes and optimal power delivery. The ECM also integrates with the braking system to enhance safety and performance. Additionally, it coordinates with ancillary components, such as the exhaust gas recirculation (EGR) system and turbocharger, to maintain efficient engine operation. This integration ensures that all systems work harmoniously to achieve the best possible truck performance 2.

Technological Advancements

The Cummins 3654717 ECM incorporates several technological innovations. It features real-time data processing capabilities, allowing it to make immediate adjustments based on current operating conditions. Adaptive learning algorithms enable the ECM to optimize performance over time by learning from past operations. Remote diagnostics capabilities allow for off-site monitoring and troubleshooting, reducing downtime and enhancing maintenance efficiency. These advancements contribute to the ECM’s effectiveness and reliability 3.

Environmental Impact

The Cummins 3654717 ECM contributes to reducing the environmental footprint of commercial trucks through efficient engine management and emissions control. By optimizing engine performance and ensuring compliance with emissions regulations, the ECM helps minimize harmful emissions. Its role in fuel efficiency also reduces the overall carbon footprint of truck operations. These contributions are significant in the ongoing efforts to make commercial transportation more sustainable and environmentally friendly 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. Founded in 1919, Cummins has a long history of innovation and excellence in the diesel engine market. The company’s product portfolio includes engines, filtration, emissions solutions, and power generation equipment. Cummins is committed to advancing technology and sustainability in the transportation and power generation industries 1.

Compatibility of Cummins Electronic Control Module (Part 3654717) with Various Engines

The Cummins Electronic Control Module (ECM), identified by part number 3654717, is designed to seamlessly integrate with a range of engine models. This ECM is engineered to provide precise control and monitoring of engine operations, ensuring optimal performance and efficiency across different engine types.

K19 and K38 Engines

The K19 and K38 engines benefit significantly from the advanced features of the 3654717 ECM. This module enhances the engines’ operational capabilities by managing fuel injection, ignition timing, and other critical parameters. The compatibility ensures that both engines can achieve higher efficiency and lower emissions, aligning with modern environmental standards 2.

K50 Engine

The K50 engine, known for its robust performance, is another beneficiary of the 3654717 ECM. This ECM provides the necessary electronic control to optimize the engine’s power output and fuel economy. The integration is designed to handle the specific demands of the K50, ensuring reliable performance in various applications 3.

M11 CELECT PLUS and M11 MECHANICAL Engines

The M11 CELECT PLUS and M11 MECHANICAL engines also feature prominently in the list of compatible engines for the 3654717 ECM. This ECM is tailored to work with the sophisticated electronic systems of the M11 CELECT PLUS, enhancing its advanced functionalities. For the M11 MECHANICAL engine, the ECM provides essential electronic control, ensuring smooth operation and efficient performance 4.

The Cummins 3654717 ECM is a versatile component that enhances the functionality of these engines by providing precise control and monitoring. Its compatibility with the K19, K38, K50, M11 CELECT PLUS, and M11 MECHANICAL engines underscores its importance in modern engine management systems.

Role of Part 3654717 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM) part 3654717 is integral to the operation and management of various engine systems. It serves as the central processing unit, coordinating and regulating multiple components to ensure optimal engine performance.

Calibration and Electronic Service Calibration

The ECM is responsible for executing calibration processes, which involve fine-tuning engine parameters to meet specific performance criteria. It utilizes electronic service calibration kits to adjust these parameters, ensuring that the engine operates within desired efficiency and emission standards 1.

Governor and Modified Centry (12V)

In conjunction with the governor, the ECM monitors and controls fuel delivery and timing. The modified centry (12V) system relies on the ECM to interpret sensor data and make real-time adjustments, enhancing engine responsiveness and stability 2.

HHP 12V VLV/ELEC Kit and N14 12V Pressure-Time Sentinel Kit

The HHP 12V VLV/ELEC kit integrates with the ECM to manage valve operations electronically, allowing for precise control over air and fuel mixtures. Similarly, the N14 12V Pressure-Time Sentinel kit depends on the ECM to monitor pressure and time metrics, ensuring that the engine maintains consistent performance under varying conditions 3.

Engine Control Module

As part of the engine control module system, the ECM part 3654717 processes data from various sensors and actuators. It adjusts fuel injection timing, air-fuel ratio, and ignition timing to optimize engine operation. This continuous feedback loop allows the ECM to make instantaneous corrections, enhancing overall engine efficiency and reliability 4.

Conclusion

In summary, the ECM part 3654717 plays a significant role in the orchestration of engine components, ensuring that each part operates in harmony to deliver peak performance. Its advanced features, compatibility with various engine models, and integration with other systems make it a crucial component in modern engine management systems.

-

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ ↩ ↩ ↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩ ↩ ↩ ↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ ↩ ↩ ↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.