This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3656990 Electrical Terminal is a component designed for use in the electrical systems of commercial trucks. Its purpose is to facilitate reliable electrical connections, ensuring the efficient operation of various electrical components within the vehicle. The significance of this terminal lies in its ability to maintain consistent and secure connections, which is vital for the overall performance and reliability of the truck’s electrical system 1.

Basic Concepts of Electrical Terminals

An electrical terminal serves as an interface that allows wires to be connected to electrical components. Its function within an electrical system is to provide a secure and conductive pathway for electrical current. By facilitating the connection between wires and components, electrical terminals ensure that electrical signals and power are transmitted efficiently and reliably 2.

Purpose of the 3656990 Electrical Terminal

This Cummins part plays a role in the electrical system of a commercial truck by ensuring reliable electrical connections. It is designed to connect wires to various electrical components, such as sensors, switches, and control modules. This terminal helps maintain the integrity of the electrical connections, which is crucial for the proper functioning of the truck’s electrical system.

Key Features

The 3656990 Electrical Terminal is characterized by several key features that enhance its performance. Its design includes a robust construction that ensures durability and longevity. The terminal is made from high-quality materials that provide excellent electrical conductivity and resistance to corrosion. Additionally, it features a secure locking mechanism that prevents accidental disconnections, ensuring a stable and reliable electrical connection.

Benefits

The benefits of using the 3656990 Electrical Terminal include improved electrical conductivity, which ensures that electrical signals and power are transmitted efficiently. Its durable construction and resistance to corrosion make it suitable for use in harsh operating conditions, common in commercial trucking environments. The secure locking mechanism enhances the reliability of the electrical connections, reducing the risk of malfunctions due to loose or disconnected terminals.

Installation Process

Proper installation of the 3656990 Electrical Terminal involves several steps to ensure a secure connection. Begin by identifying the correct location for the terminal within the electrical system. Use the appropriate tools to strip the insulation from the wire, exposing the conductor. Insert the wire into the terminal, ensuring it is fully seated. Engage the locking mechanism to secure the connection. Finally, verify the connection by testing for continuity and ensuring there are no loose or exposed wires.

Troubleshooting Common Issues

Common problems that may arise with the 3656990 Electrical Terminal include loose connections and corrosion. To address these issues, first, inspect the terminal for any signs of wear or damage. Ensure that the wire is fully seated within the terminal and that the locking mechanism is engaged. If corrosion is present, clean the terminal and wire using a suitable contact cleaner. Replace the terminal if it shows significant wear or if the locking mechanism is compromised.

Maintenance Tips

To ensure optimal performance of the 3656990 Electrical Terminal, regular maintenance is recommended. Inspect the terminal periodically for signs of wear, corrosion, or loose connections. Clean the terminal and surrounding area using a contact cleaner to remove any dirt or debris that may affect the connection. Follow the manufacturer’s guidelines for replacement if the terminal shows signs of significant wear or if performance issues arise.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the diesel engine and related technology markets. The company’s commitment to excellence is reflected in its wide range of products, including the 3656990 Electrical Terminal, which is designed to meet the demanding requirements of commercial trucking applications.

Role of Part 3656990 Electrical Terminal in Engine Systems

The 3656990 Electrical Terminal is integral to the seamless operation of various engine systems by ensuring reliable electrical connections. This component is employed in multiple areas including accessories, electrical systems, wiring, braces and harnesses, brake systems, engine components, and electronic control module (ECM) wiring harnesses.

Accessories and Electrical Systems

In accessories and electrical systems, the 3656990 Electrical Terminal facilitates the connection between various electrical components and the power source. It ensures that accessories such as lights, sensors, and other electronic devices receive a consistent and safe electrical supply. This terminal is often found in wiring harnesses that distribute power throughout the engine compartment and beyond.

Wiring and Harnesses

Within wiring and harnesses, the 3656990 Electrical Terminal plays a significant role in maintaining the integrity of the electrical connections. It is used in both the top-level assembly harness and individual wiring harnesses to connect wires to sensors, actuators, and other components. This ensures that signals and power are transmitted efficiently without interference or loss.

Brake Systems

In brake systems, the Electrical Terminal is used in the wiring harnesses that connect the brake control module to various sensors and actuators. This ensures that the brake system can respond accurately to driver inputs and environmental conditions, enhancing safety and performance.

Engine and ECM Wiring

For the engine and ECM wiring, the 3656990 Electrical Terminal is essential in the engine control wiring harness. It connects the ECM to various engine sensors and actuators, allowing for precise monitoring and control of engine operations. This includes connections to the electronic engine monitor and other critical components that ensure the engine runs efficiently and within specified parameters.

Plumbing and Engine Control Module

Although primarily electrical, the terminal also interfaces with plumbing systems where electrical signals control fluid flow in systems like fuel injection and cooling. The engine control module (ECM) relies on these terminals to communicate with various engine control components, ensuring that all systems work in harmony.

Wiring Accessories

Lastly, in wiring accessories, the 3656990 Electrical Terminal is used to connect additional electrical components that may not be part of the primary engine system but are necessary for the vehicle’s operation. This includes aftermarket accessories and upgrades that require a secure and reliable electrical connection.

Conclusion

The Cummins 3656990 Electrical Terminal is a vital component in the electrical systems of commercial trucks, ensuring reliable and efficient electrical connections across various engine systems. Its robust design, durable construction, and secure locking mechanism contribute to the overall performance and reliability of the truck’s electrical system. Regular maintenance and proper installation are key to maximizing the benefits of this terminal.

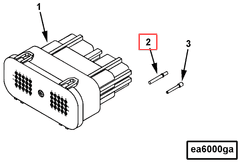

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.