This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3658860 Electronic Control Module Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins is renowned for its commitment to quality and innovation in manufacturing truck components. This wiring harness is integral to the electrical system of trucks, facilitating the communication and power distribution necessary for optimal performance 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module (ECM) Wiring Harness is a network of wires and connectors that link the ECM to various sensors, actuators, and other electronic components within a truck’s electrical system. It consists of multiple wires, each serving a specific function, encased in a durable housing to protect against environmental factors. The harness enables the ECM to receive data from sensors, send commands to actuators, and manage the electrical power distribution throughout the vehicle 2.

Role of the 3658860 Wiring Harness in Truck Operation

The 3658860 Wiring Harness plays a significant role in the overall operation of a truck by providing the necessary connections between the ECM and other electronic systems. It ensures that the ECM can effectively monitor and control various truck functions, including engine performance, transmission operations, and emissions systems. The harness facilitates real-time data exchange, allowing the ECM to make adjustments and optimizations as needed 3.

Key Features of the 3658860 Wiring Harness

The 3658860 Wiring Harness is designed with several key features that enhance its performance and reliability. It is constructed using high-quality materials that offer resistance to wear, corrosion, and environmental factors. The harness includes precise wiring configurations to ensure accurate signal transmission and power distribution. Additionally, it features robust connectors and terminals that provide secure and durable connections, minimizing the risk of electrical issues.

Benefits of Using the 3658860 Wiring Harness

Utilizing the 3658860 Wiring Harness offers several benefits. Its high-quality construction and precise design contribute to improved reliability and efficiency within the truck’s electrical system. The harness is engineered to integrate seamlessly with modern truck systems, ensuring compatibility and optimal performance. It also supports the ECM in managing complex truck functions, leading to enhanced overall vehicle performance.

Installation and Integration

Proper installation and integration of the 3658860 Wiring Harness are crucial for ensuring its effective operation. It is important to follow manufacturer guidelines during installation to maintain the integrity of the electrical system. The harness should be routed carefully to avoid damage from sharp edges or excessive heat. Secure connections must be ensured at all terminals to prevent electrical issues. Integration with the truck’s existing electrical system requires careful planning to avoid conflicts and ensure smooth operation.

Troubleshooting Common Issues

When troubleshooting common issues with the 3658860 Wiring Harness, it is important to start with a thorough inspection of the wiring and connections. Look for signs of wear, corrosion, or damage that may affect performance. Diagnostic tools can be used to identify specific issues within the electrical system. Common solutions may include repairing or replacing damaged wires, tightening loose connections, or addressing issues with the ECM or other connected components.

Maintenance and Care

Regular maintenance and care of the 3658860 Wiring Harness are essential for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the harness to remove dirt and debris, and ensuring that all connections remain secure. Addressing any issues promptly can prevent more significant problems down the line and contribute to the overall reliability of the truck’s electrical system.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the industry. Known for its commitment to quality and innovation, Cummins has established itself as a leader in the production of truck components. The company’s dedication to research and development ensures that its products, including the 3658860 Wiring Harness, meet the highest standards of performance and reliability. Cummins’ reputation is built on its ability to deliver durable, efficient, and technologically advanced solutions for the commercial trucking industry.

Electronic Control Module Wiring Harness (Part 3658860) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, identified by part number 3658860 and manufactured by Cummins, is a critical component in ensuring seamless communication and power distribution between the ECM and various engine control units. This wiring harness is designed to interface with several Cummins engine models, facilitating efficient engine operation and diagnostics.

K50 Series

The K50 series engines, known for their robust performance and reliability, are among the models that benefit from the ECM Wiring Harness 3658860. This harness is engineered to connect the ECM to the engine’s sensors, actuators, and other electronic control units, ensuring that all components work in harmony. The harness is designed to withstand the harsh conditions typically encountered in heavy-duty applications, providing a durable and reliable connection.

Integration with Cummins Engines

The ECM Wiring Harness 3658860 is meticulously designed to integrate with Cummins engines, ensuring compatibility and ease of installation. The harness is tailored to fit the specific electrical architecture of Cummins engines, allowing for precise and efficient signal transmission. This compatibility is crucial for maintaining optimal engine performance and ensuring that diagnostic trouble codes are accurately reported and managed.

Importance of the Wiring Harness

The ECM Wiring Harness 3658860 plays a pivotal role in the overall functionality of Cummins engines. By providing a reliable and secure connection between the ECM and other engine components, it ensures that the engine operates smoothly and efficiently. This harness is essential for maintaining the integrity of the engine’s electronic control systems, which are critical for performance, fuel efficiency, and emissions control.

Installation and Maintenance

Proper installation of the ECM Wiring Harness 3658860 is essential to ensure that it functions correctly. Technicians should follow the manufacturer’s guidelines for installation, ensuring that all connections are secure and that the harness is routed to avoid interference with other engine components. Regular maintenance checks should be performed to ensure that the harness remains in good condition and that there are no signs of wear or damage.

Role of Part 3658860 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness (Part 3658860) is integral to the operation of various engine systems, ensuring seamless communication and power distribution between the ECM and other components. Here’s how it interfaces with several key components:

Integration with High-Horsepower (HHP) Systems

- Kit, HHP 12V Valve/Electrical: The wiring harness provides the necessary electrical connections for the 12V valve system, enabling precise control over fuel delivery and valve operation. This ensures optimal performance and efficiency in high-horsepower applications.

- Kit, HHP 24V Valve/Electrical: Similarly, for the 24V valve system, the harness facilitates the higher voltage requirements, allowing for enhanced control and responsiveness in more demanding engine configurations.

Pressure-Time Systems

- N14 12V Pressure-Time Sentinel Kit: The harness connects the 12V pressure-time sentinel kit to the ECM, allowing for real-time monitoring and adjustment of pressure parameters. This integration is vital for maintaining engine health and performance under varying conditions.

- N14 24V Hardware-Pressure-Time Valve/Mounting Kit: For the 24V system, the wiring harness ensures that the pressure-time valve receives the correct signals and power, contributing to consistent and reliable engine operation.

Oil Replenishing System

- System, Oil Replenishing: The harness plays a role in the oil replenishing system by providing the electrical connections needed for sensors and actuators. This ensures that the system can accurately monitor oil levels and replenish as necessary, maintaining lubrication and protecting engine components.

General System Integration

- Across all these systems, the ECM Wiring Harness acts as the central nervous system, transmitting data and power to and from the ECM. This facilitates the ECM’s ability to make real-time adjustments, optimize performance, and ensure the engine operates within safe parameters.

Conclusion

In summary, the ECM Wiring Harness (Part 3658860) is a fundamental component that enhances the functionality and reliability of various engine systems by providing essential electrical connections and communication pathways. Its role in facilitating real-time data exchange and power distribution is critical for maintaining optimal engine performance and ensuring the integrity of the engine’s electronic control systems.

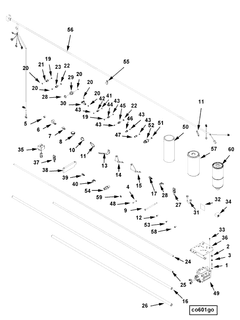

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.