This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

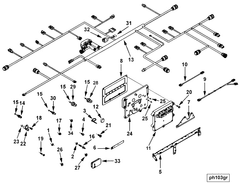

The Electronic Control Module Bracket, identified by part number 3680878, is a component manufactured by Cummins, a leader in the commercial truck industry. This Cummins part plays a significant role in the mounting and protection of the Electronic Control Module (ECM) within commercial trucks. Its design and functionality are integral to the reliable operation of the truck’s electronic systems 1.

Function and Operation

This part serves as a mounting solution for the ECM, ensuring it is securely positioned within the vehicle. It facilitates the ECM’s interaction with various electronic components, allowing for efficient communication and data exchange. By providing a stable platform, it contributes to the overall functionality and reliability of the truck’s electronic system 2.

Key Features

Designed with durability in mind, the Electronic Control Module Bracket is constructed from high-quality materials that resist corrosion and physical damage. Its design includes multiple mounting options, allowing for flexible installation across different truck models. Compatibility with Cummins engines ensures that it meets the stringent requirements for performance and reliability in commercial applications 3.

Benefits

The use of the Electronic Control Module Bracket offers several advantages. It enhances the protection of the ECM from environmental factors and physical impacts, contributing to the longevity of the electronic system. The bracket’s design also simplifies the installation process, reducing downtime during maintenance or upgrades. Furthermore, its robust construction supports the reliability of the truck’s electronic systems, leading to improved overall vehicle performance 4.

Installation Process

Installing the Electronic Control Module Bracket requires careful attention to detail. The process involves securing the bracket in the designated location, ensuring proper alignment with the ECM and other components. Necessary tools include a torque wrench for tightening bolts to the specified torque settings. Precautions should be taken to avoid damaging the ECM or surrounding components during installation.

Maintenance and Troubleshooting

Regular maintenance of the Electronic Control Module Bracket involves inspecting it for signs of wear or damage and ensuring that all mounting bolts are secure. Common issues may include corrosion or loosening of the bracket, which can affect the ECM’s performance. Troubleshooting steps include cleaning the bracket and tightening or replacing any compromised bolts to maintain optimal performance and longevity.

Integration with Cummins Systems

The Electronic Control Module Bracket is designed to seamlessly integrate with Cummins’ engine management systems. This integration enhances the overall vehicle performance by ensuring the ECM is securely mounted and operates within the optimal environmental conditions. It also facilitates diagnostics by providing a stable platform for the ECM, allowing for accurate data collection and analysis.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to innovation is evident in its extensive product range, which includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Role of Part 3680878 Electronic Control Module (ECM) Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 3680878, is a critical component in the integration and functionality of modern engine systems. This Cummins part plays a significant role in securing and positioning the ECM within the engine assembly, ensuring optimal performance and reliability.

Integration with the Cylinder Block

The cylinder block serves as the structural foundation of the engine, housing the cylinders, pistons, and other critical components. The ECM Bracket is strategically mounted to the cylinder block, providing a stable and secure platform for the ECM. This arrangement ensures that the ECM remains firmly in place, even under the dynamic conditions experienced during engine operation. The secure mounting of the ECM is vital for maintaining the integrity of the electrical connections and the overall functionality of the engine control system.

Connection to the Engine Control Module

The ECM is the brain of the engine, responsible for managing various functions such as fuel injection, ignition timing, and emissions control. The ECM Bracket is designed to hold the ECM in a location that allows for efficient heat dissipation and easy access for service and maintenance. By providing a dedicated mounting point, the bracket ensures that the ECM is positioned away from high-temperature areas within the engine compartment, thereby enhancing its longevity and performance. Additionally, the bracket facilitates the routing of wiring harnesses and connectors, ensuring a tidy and organized installation that minimizes the risk of electrical faults.

Interaction with the Front Gear Housing

The front gear housing is a component that encloses the front gears and other related parts within the engine. In many engine designs, the ECM Bracket is positioned in close proximity to the front gear housing. This proximity allows for the integration of sensors and actuators that are essential for the ECM to monitor and control various engine parameters. The bracket provides a stable base for these sensors, ensuring accurate readings and reliable data transmission to the ECM. Furthermore, the ECM Bracket aids in the structural integrity of the front gear housing by distributing loads and vibrations, contributing to the overall stability of the engine system.

Conclusion

In summary, the ECM Bracket (part 3680878) is a pivotal component that enhances the functionality and reliability of the engine system by securely mounting the ECM, facilitating efficient heat management, and ensuring the proper integration of sensors and actuators. Its role in the engine assembly underscores the importance of precise engineering and thoughtful design in modern automotive technology.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.