3824811

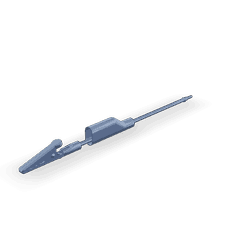

Electrical Test Lead

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3824811 Electrical Test Lead is a specialized tool designed for the maintenance and diagnostics of commercial trucks. It is a vital component in the toolkit of mechanics and technicians, facilitating the accurate diagnosis of electrical issues within these vehicles. This part ensures the reliability and efficiency of commercial trucks, which are integral to various industries and logistics operations.

Basic Concepts of Electrical Test Leads

An electrical test lead is a conductive wire with connectors on each end, used to measure electrical parameters such as voltage, current, and resistance. In the context of commercial trucks, these test leads are indispensable for diagnosing issues within the electrical systems. They allow technicians to connect diagnostic equipment to specific points in the electrical circuit, providing data that can pinpoint faults or inefficiencies 1.

Purpose of the Cummins 3824811 Electrical Test Lead

The Cummins 3824811 Electrical Test Lead is specifically engineered to aid in the diagnostic procedures of commercial trucks. It is utilized to connect diagnostic tools to the truck’s electrical system, enabling the measurement and analysis of electrical signals. This test lead plays a role in identifying issues within the electrical circuits, sensors, and other components, thereby facilitating timely and accurate repairs 2.

Key Features

The Cummins 3824811 Electrical Test Lead is characterized by its robust design and high-quality materials, which ensure durability and reliable performance. It features sturdy connectors that provide secure connections to both the diagnostic equipment and the truck’s electrical system. The lead is also designed to be flexible, allowing for easy maneuverability in tight spaces, which is often necessary when working on commercial trucks.

Benefits of Using the Cummins 3824811 Electrical Test Lead

Utilizing the Cummins 3824811 Electrical Test Lead offers several advantages. It enhances diagnostic accuracy by providing a stable and reliable connection, which is crucial for obtaining precise measurements. The ease of use, thanks to its design and flexibility, allows technicians to work efficiently. Additionally, its durability ensures that it can withstand the rigors of frequent use in a commercial setting 3.

Troubleshooting and Maintenance Suggestions

To maintain the Cummins 3824811 Electrical Test Lead in optimal condition, regular inspection for wear and damage is recommended. Cleaning the connectors to ensure good conductivity and storing the lead in a dry, cool place can prevent deterioration. If issues arise, such as poor connectivity or inaccurate readings, checking the lead for physical damage and ensuring it is properly connected can often resolve the problem.

Application in Commercial Truck Diagnostics

The Cummins 3824811 Electrical Test Lead is employed in a variety of diagnostic scenarios within commercial trucks. It is used to test engine systems, diagnose issues within electrical circuits, and check the functionality of sensors. Its application is broad, covering many aspects of truck maintenance and repair, making it a versatile tool in the technician’s arsenal.

Safety Considerations

When using the Cummins 3824811 Electrical Test Lead, it is important to observe safety guidelines to protect both the user and the equipment. This includes ensuring the truck’s electrical system is powered down before connecting the test lead, using insulated tools to avoid electric shock, and following all manufacturer instructions for use. Safety is paramount in any diagnostic procedure involving electrical systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name among professionals in the field.

Role of Part 3824811 Electrical Test Lead in Engine Systems

When diagnosing and maintaining engine systems, the 3824811 Electrical Test Lead is an indispensable tool that facilitates the testing and troubleshooting of various electrical components. This test lead is particularly useful when working with the wiring harness repair kit, as it allows for the precise identification of faults within the electrical system.

The 3824811 Electrical Test Lead is employed to connect to different points within the engine’s electrical circuitry, enabling engineers and mechanics to measure voltage, check for continuity, and identify any breaks or shorts in the wiring. This is especially important when using a wiring harness repair kit, as it ensures that each repaired section of the harness is functioning correctly before reassembling the engine system.

Furthermore, the test lead aids in the verification of sensor outputs and the functionality of actuators. For instance, when repairing or replacing sections of the wiring harness, the 3824811 Electrical Test Lead can be used to test the connections to fuel injectors, ensuring that they receive the correct signals from the engine control unit (ECU). Similarly, it can be utilized to check the integrity of ground connections, which are vital for the proper operation of all electrical components within the engine system.

Conclusion

In summary, the Cummins 3824811 Electrical Test Lead plays a significant role in maintaining and repairing engine systems by providing a means to accurately diagnose and verify the electrical integrity of components, particularly when working alongside a wiring harness repair kit.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.