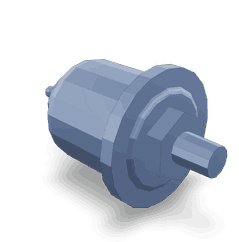

The Cummins 3897170 Transducer is a specialized component designed for use in heavy-duty trucks. It serves a significant role in the vehicle’s operation by converting various types of energy into electrical signals that can be interpreted by the truck’s electronic systems. This part is integral to ensuring that the truck operates efficiently and reliably under demanding conditions.

Basic Concepts of Transducers

A transducer is a device that converts one form of energy into another. In automotive systems, transducers are commonly used to convert physical parameters such as pressure, temperature, or motion into electrical signals. These signals are then used by the vehicle’s electronic control units (ECUs) to make adjustments and ensure optimal performance. There are several types of transducers, including pressure transducers, temperature transducers, and position transducers, each serving specific functions within the vehicle’s systems 2.

Purpose of the 3897170 Transducer

The Cummins 3897170 Transducer plays a role in the operation of a truck by providing accurate data to the vehicle’s electronic systems. It interfaces with various systems, including the engine control module (ECM) and other critical components, to monitor and adjust performance parameters. By converting physical measurements into electrical signals, the transducer helps maintain the truck’s efficiency and reliability 3.

Key Features

The Cummins 3897170 Transducer is characterized by several key features and technical specifications. Its design incorporates high-quality materials to ensure durability and accuracy. The transducer is engineered to withstand the harsh environments typical of heavy-duty truck applications. Unique attributes include its precision in signal conversion and its compatibility with Cummins’ electronic systems 4.

Benefits of Using the 3897170 Transducer

Incorporating the Cummins 3897170 Transducer into truck systems offers several advantages. It contributes to improvements in efficiency by providing accurate data that allows the ECM to make precise adjustments. This results in enhanced performance and increased reliability of the truck. The transducer also helps in reducing maintenance costs by enabling early detection of potential issues through continuous monitoring 1.

Installation and Integration

Proper installation and integration of the Cummins 3897170 Transducer are vital for ensuring its effective operation. Guidelines for installation include careful alignment with the truck’s systems and secure mounting to prevent damage from vibrations. Best practices involve following the manufacturer’s instructions and conducting thorough testing post-installation to confirm proper functionality. Potential challenges may include ensuring compatibility with existing systems and addressing any wiring issues 2.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3897170 Transducer include signal inaccuracies and physical damage. Troubleshooting steps involve checking connections, verifying signal integrity, and inspecting the transducer for any signs of wear or damage. Maintenance tips to ensure longevity and optimal performance include regular inspection, cleaning, and calibration as needed. Promptly addressing any detected issues can prevent more significant problems down the line 3.

Performance Monitoring

Monitoring the performance of the Cummins 3897170 Transducer is crucial for maintaining the truck’s efficiency. Diagnostic tools and techniques used by mechanics and engineers include using specialized software to read and interpret the transducer’s signals. Regular performance checks help in identifying any deviations from normal operation, allowing for timely interventions 4.

Safety Considerations

When working with the Cummins 3897170 Transducer, it is important to follow safety guidelines and precautions. Potential hazards include electrical risks and the possibility of injury from moving parts. Mitigating these risks involves ensuring that the truck is properly shut down before beginning any work, using insulated tools, and wearing appropriate personal protective equipment (PPE) 1.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to excellence, which is reflected in its wide range of products, including the Cummins 3897170 Transducer. Cummins’ dedication to quality and performance ensures that its components meet the demanding requirements of heavy-duty truck applications 2.

Cummins Transducer Part 3897170 Compatibility

The Cummins transducer part number 3897170 is designed to integrate seamlessly with specific engine models, ensuring optimal performance and reliability. This transducer is a critical component for monitoring and controlling engine functions, providing essential data for engine management systems.

Engine Compatibility

6B5.9 and 6C8.3 Engines

The transducer part 3897170 is engineered to fit perfectly with the 6B5.9 and 6C8.3 engines. These engines, known for their robust performance and efficiency, benefit from the precise data acquisition and transmission capabilities of this transducer.

Installation and Integration

For the 6B5.9 and 6C8.3 engines, the installation of the transducer involves precise alignment and secure mounting to ensure accurate readings. The transducer’s design allows for easy integration into the engine’s existing systems, facilitating a smooth transition and minimal disruption during installation.

Performance Benefits

When properly installed, the transducer enhances the engine’s operational efficiency by providing real-time data to the engine control unit (ECU). This data is crucial for maintaining optimal engine performance, reducing wear and tear, and extending the engine’s lifespan.

Maintenance and Reliability

Regular maintenance of the transducer is essential to ensure its longevity and reliability. This includes periodic checks for any signs of wear or damage and ensuring that the mounting hardware remains secure. Cummins recommends following the manufacturer’s guidelines for maintenance to maximize the transducer’s performance and lifespan 3.

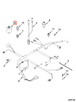

Role of Part 3897170 Transducer in Engine Systems

The Part 3897170 Transducer is an integral component in the seamless operation of various engine systems. It works in conjunction with the engine harness to ensure that electrical signals are accurately transmitted between the engine and its control systems. This part is responsible for converting physical parameters, such as pressure or temperature, into electrical signals that can be interpreted by the engine’s electronic control unit (ECU).

In the context of the wiring, the transducer ensures that all connections are precise and reliable. It interfaces directly with the wiring to maintain signal integrity, which is essential for the accurate monitoring and control of engine functions.

When integrated with the engine panel, the transducer provides real-time data that is displayed to the operator. This data is vital for making informed decisions regarding engine performance and maintenance. The transducer’s ability to deliver accurate readings ensures that the panel displays reliable information, contributing to safer and more efficient engine operation.

Finally, the transducer plays a significant role in the engine instrument system. It feeds critical data to the instruments, allowing for the precise measurement of various engine parameters. This information is used to adjust engine operations, ensuring optimal performance and longevity. The transducer’s reliable data transmission is fundamental to the overall functionality and efficiency of the engine instrument system 4.

Conclusion

The Cummins 3897170 Transducer is a vital component in the operation of heavy-duty trucks, providing accurate data to the vehicle’s electronic systems to ensure efficient and reliable performance. Its key features, benefits, and compatibility with specific engine models make it an essential part of modern diesel technology. Proper installation, maintenance, and monitoring are crucial for maximizing the performance and longevity of this Cummins part.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ ↩ ↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ ↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.