This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

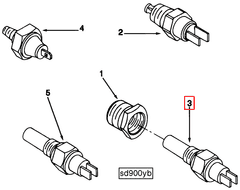

The Cummins 3906275 Transducer is a specialized component designed for use in commercial truck operations. Its purpose is to convert one form of energy into another, facilitating the monitoring and regulation of various systems within the truck. This part is significant in ensuring the efficient and reliable operation of commercial trucks, contributing to overall performance and safety.

Basic Concepts of Transducers

A transducer is a device that converts one type of energy into another. In automotive systems, transducers are commonly used to convert physical parameters such as pressure, temperature, or motion into electrical signals. These signals can then be interpreted by the vehicle’s electronic control systems to make adjustments and ensure optimal performance. Transducers play a vital role in modern automotive technology by providing real-time data that helps in the precise control of various vehicle functions 1.

Role of the 3906275 Transducer in Truck Operation

The Cummins 3906275 Transducer is integral to the operation of commercial trucks by providing accurate measurements of specific parameters. It is typically used to monitor and regulate systems such as fuel injection, engine performance, and emissions control. By converting physical measurements into electrical signals, the transducer allows the truck’s electronic control unit (ECU) to make necessary adjustments in real-time. This integration ensures that the truck operates efficiently, meets emissions standards, and maintains optimal performance under varying conditions 2.

Key Features

The Cummins 3906275 Transducer is designed with several key features that enhance its functionality and reliability. Its construction includes high-quality materials that ensure durability in the demanding environment of commercial truck operations. The transducer is engineered to provide precise measurements, with technological specifications that ensure accuracy and consistency. Additionally, its design allows for easy integration into the truck’s existing systems, minimizing the need for complex modifications 3.

Benefits of Using the 3906275 Transducer

Utilizing the Cummins 3906275 Transducer offers several advantages in truck operations. It contributes to improved performance by providing accurate data that allows the ECU to make precise adjustments. This results in enhanced fuel efficiency, reduced emissions, and overall better engine performance. The transducer also increases the reliability of the truck’s systems by ensuring that all components operate within their optimal parameters. Furthermore, its integration into the truck’s systems enhances efficiency by streamlining the monitoring and regulation processes.

Installation and Integration

Proper installation and integration of the Cummins 3906275 Transducer are crucial for its effective operation. Installation should be performed according to the manufacturer’s guidelines to ensure compatibility with the truck’s systems. This may involve connecting the transducer to the appropriate sensors and wiring it into the ECU. It is important to verify that all connections are secure and that the transducer is correctly positioned to provide accurate readings. Any prerequisites, such as system updates or calibrations, should be completed before installation.

Troubleshooting Common Issues

Common issues associated with the Cummins 3906275 Transducer may include inaccurate readings, failure to communicate with the ECU, or physical damage to the transducer. Troubleshooting these issues involves checking the connections to ensure they are secure and undamaged. If the transducer is not providing accurate readings, calibrating it according to the manufacturer’s instructions may resolve the issue. Physical damage to the transducer may require replacement. Regular inspections and maintenance can help identify and address potential issues before they become significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3906275 Transducer is essential to ensure its longevity and optimal performance. This includes periodic inspections to check for any signs of wear or damage. Cleaning the transducer and its connections can prevent buildup that may interfere with its operation. Additionally, ensuring that the transducer is calibrated correctly and that all software updates are installed can help maintain its accuracy and reliability. Following the manufacturer’s maintenance schedule will help ensure that the transducer continues to function effectively throughout its lifespan.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck operators. Cummins’ commitment to innovation and quality has made it a trusted name in the industry.

Cummins Transducer Part 3906275 Compatibility

The Cummins transducer part number 3906275 is designed to integrate seamlessly with specific engine models, ensuring optimal performance and reliability. This transducer is engineered to work with the following Cummins engine series:

-

4B3.9 Series: The 3906275 transducer is a critical component for the 4B3.9 engines, providing essential data for engine management systems. Its precision and durability make it an ideal fit for these engines, enhancing overall operational efficiency.

-

6B5.9 Series: Similarly, the 3906275 transducer is compatible with the 6B5.9 engines. This part ensures that the engine’s performance metrics are accurately monitored and managed, contributing to the longevity and effectiveness of the engine.

Both engine series benefit from the advanced design of the 3906275 transducer, which is tailored to meet the specific needs of these Cummins engines. Its integration into these systems is straightforward, thanks to its compatibility with the engine’s architecture and requirements.

The 3906275 transducer is integral to the seamless operation of various engine systems, particularly in the realms of engine instrumentation and monitoring. This component facilitates the conversion of physical parameters—such as pressure, temperature, and rotational speed—into electrical signals. These signals are then transmitted to the engine instrumentation system, where they are processed and displayed on the engine instrument panel.

The role of the transducer in engine instrumentation is to ensure that all engine parameters are accurately measured and conveyed. This allows for real-time monitoring of engine performance, enabling engineers and mechanics to make informed decisions based on precise data. The transducer’s output is vital for the engine monitor, which relies on consistent and reliable data to assess the engine’s condition and performance.

In addition, the transducer interfaces with the engine instrument panel, providing essential readings that are critical for both diagnostic and operational purposes. The data from the transducer helps in maintaining optimal engine performance, identifying potential issues before they escalate, and ensuring that the engine operates within specified parameters.

Overall, the integration of the 3906275 transducer within these systems enhances the accuracy and reliability of engine monitoring, contributing to safer and more efficient engine operations.

Conclusion

The Cummins 3906275 Transducer plays a crucial role in the efficient and reliable operation of commercial trucks. By providing accurate measurements and facilitating real-time adjustments, this part ensures that trucks meet performance and emissions standards. Its integration into truck systems enhances monitoring and regulation processes, contributing to improved fuel efficiency, reduced emissions, and overall better engine performance. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.