This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3917123 Transducer is a specialized component designed for use in commercial trucks. Manufactured by Cummins Inc., a leading name in the diesel engine and power generation industries, this part serves a specific purpose within the truck’s operational systems. Its design and functionality are tailored to meet the demanding requirements of commercial trucking, ensuring reliable performance and integration within the vehicle’s systems.

Basic Concepts of Transducers

A transducer is a device that converts one form of energy into another. In automotive and industrial applications, transducers are commonly used to convert physical parameters such as pressure, temperature, or motion into electrical signals. These signals can then be interpreted by electronic systems to monitor, control, and optimize various functions. The versatility of transducers makes them invaluable across a wide range of industries, including automotive, aerospace, and manufacturing, where precise measurement and control are paramount 1.

Role of the 3917123 Transducer in Truck Operation

The Cummins 3917123 Transducer plays a role in the operation of a commercial truck by providing accurate measurements that are critical for the truck’s electronic control systems. It is integrated into the truck’s systems to monitor specific parameters, allowing for precise adjustments and optimizations in real-time. This integration ensures that the truck operates efficiently, with minimal impact on performance or safety.

Key Features

The Cummins 3917123 Transducer is characterized by several key features that enhance its performance and reliability. Its design incorporates advanced materials and technology to ensure durability and accuracy under the demanding conditions of commercial trucking. The transducer’s construction allows it to withstand the vibrations, temperature fluctuations, and other environmental factors encountered in truck operations. Additionally, its technological advancements contribute to improved signal accuracy and reliability, making it a valuable component in the truck’s system 2.

Benefits of Using the 3917123 Transducer

Utilizing the Cummins 3917123 Transducer offers several advantages. It contributes to improved efficiency by providing accurate data that allows for fine-tuning of the truck’s systems. This precision can lead to better fuel economy and reduced emissions, aligning with industry trends towards more sustainable operations. Furthermore, the transducer’s reliability enhances the overall safety and performance of the truck, ensuring that it operates within optimal parameters 3.

Installation and Integration

Proper installation and integration of the Cummins 3917123 Transducer into a truck’s system are crucial for its effective operation. Guidelines for installation include ensuring that the transducer is correctly positioned and securely mounted to withstand the operational environment. Integration into the truck’s systems requires careful calibration to ensure that the transducer’s readings are accurately interpreted by the truck’s electronic control units. Following manufacturer recommendations for installation and integration is advised to maintain the transducer’s performance and longevity.

Troubleshooting and Maintenance

Common issues with the Cummins 3917123 Transducer may include inaccurate readings or failure to communicate with the truck’s systems. Troubleshooting these issues involves checking the transducer’s connections, ensuring it is properly calibrated, and verifying that there are no external factors affecting its performance. Regular maintenance practices, such as cleaning the transducer and inspecting its connections, can help prevent issues and ensure optimal performance. Addressing problems promptly and performing routine maintenance can extend the transducer’s lifespan and maintain its accuracy.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company’s product range includes diesel and natural gas engines, as well as related technologies that enhance the efficiency, reliability, and sustainability of its offerings. Cummins’ commitment to innovation and quality has solidified its position as a leader in the commercial vehicle sector, providing solutions that meet the evolving needs of the industry.

Compatibility with Cummins Engines

The Cummins part 3917123, a Transducer, is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is specifically engineered to fit with the 4B3.9, 6B5.9, and 6C8.3 engines, providing critical data and feedback that enhances engine efficiency and operational effectiveness.

For the 4B3.9 and 6B5.9 engines, the transducer plays a vital role in monitoring and adjusting various engine parameters. Its precision in data collection helps maintain the balance and performance of these engines, ensuring they operate at peak efficiency.

Similarly, the 6C8.3 engine benefits from the transducer’s capabilities, as it provides essential data that aids in the fine-tuning of engine operations. This ensures that the engine runs smoothly and efficiently, reducing the risk of wear and tear.

In addition to these engines, the transducer is also compatible with the K19, K38, and K50 engines. This compatibility extends the part’s utility across a broader range of engine models, making it a versatile component in the Cummins engine ecosystem.

The design of the transducer ensures that it can be easily integrated into these engines, with minimal disruption to the existing systems. Its robust construction and precise engineering make it a reliable choice for maintaining engine performance across various applications.

Role of Part 3917123 Transducer in Engine Systems

The Part 3917123 Transducer is an integral component in the orchestration of engine instrumentation and monitoring systems. It serves as a pivotal link in the chain of data acquisition and display, ensuring that the engine’s operational parameters are accurately captured and conveyed.

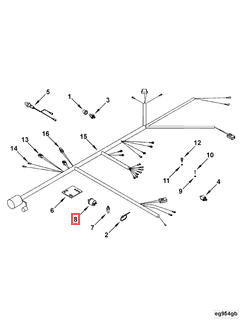

Integration with Engine Instrumentation

In the realm of engine instrumentation, the Transducer 3917123 is responsible for converting physical parameters such as pressure, temperature, and flow rates into electrical signals. These signals are then relayed through the engine’s wiring harness to the instrument panel, where they are interpreted and displayed to the operator. This seamless conversion and transmission are essential for the real-time monitoring of engine performance.

Wiring and Harness Compatibility

The transducer’s electrical output is designed to be compatible with the engine’s wiring harness. This ensures that the signals are transmitted without loss or distortion, maintaining the integrity of the data as it travels from the transducer to the instrument panel. The wiring must be correctly installed and maintained to prevent any interference that could lead to inaccurate readings.

Instrument Panel Display

Upon reaching the instrument panel, the electrical signals from the Transducer 3917123 are processed and displayed as readable data. This could include gauges for oil pressure, temperature indicators, or flow rate meters. The accuracy of these readings is dependent on the transducer’s precise conversion of physical parameters, highlighting the importance of its role in the system.

Oil Block Connection

The Transducer 3917123 often interfaces directly with the oil block connection, where it monitors the oil pressure within the engine. This connection is vital for ensuring that the engine is lubricated properly and that there are no blockages or leaks in the oil system that could lead to engine damage.

Engine Instrument and System Monitoring

Beyond individual gauges, the transducer’s data feeds into the broader engine monitoring system. This system uses the data to perform complex analyses of engine health, efficiency, and performance. The Transducer 3917123’s role in this system is to provide the foundational data points that are essential for these analyses.

Engine Monitoring Panel

The engine monitoring panel, which may be a part of the instrument panel or a separate unit, relies on the data from the Transducer 3917123 to provide a comprehensive overview of the engine’s condition. This panel may include alarms and warnings that are triggered based on the transducer’s readings, alerting operators to potential issues before they become critical.

Conclusion

In summary, the Part 3917123 Transducer is a key player in the engine’s data acquisition and display network. Its accurate conversion of physical parameters into electrical signals is fundamental to the engine’s instrumentation, wiring, and monitoring systems, ensuring that operators have the information they need to maintain and operate the engine effectively.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.