This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

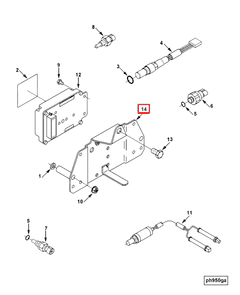

The Electronic Control Module Bracket, identified by part number 3933468, is a component manufactured by Cummins, a leading name in the automotive industry, particularly known for its diesel engines and related components. This Cummins part plays a significant role in heavy-duty trucks by providing a secure mounting solution for the Electronic Control Module (ECM). Cummins, with its extensive experience and reputation for quality, ensures that this part meets the demanding requirements of heavy-duty applications 1.

Function and Operation

The Electronic Control Module Bracket serves as a foundational element in the truck’s electronic system. It is designed to securely hold the ECM, which is responsible for managing various engine functions and ensuring optimal performance. By providing a stable and protected environment for the ECM, the bracket contributes to the overall efficiency and reliability of the truck’s electronic system. Its role is pivotal in maintaining the integrity of the ECM under varying operational conditions 2.

Key Features

The design of the Electronic Control Module Bracket is characterized by its robust construction and strategic mounting provisions. Crafted from high-quality materials, it offers durability and resistance to the harsh conditions often encountered in heavy-duty truck operations. The bracket is engineered to fit seamlessly with Cummins engines, ensuring compatibility and ease of integration into the truck’s existing system. Its design considerations include provisions for secure attachment, which aids in the stability and protection of the ECM 3.

Benefits

Incorporating the Electronic Control Module Bracket into a truck’s system offers several advantages. It provides enhanced protection for the ECM, shielding it from physical damage and environmental factors that could impair its function. This protection contributes to the overall reliability of the truck’s electronic system. Additionally, the bracket’s design facilitates ease of installation, allowing for straightforward integration into the vehicle’s architecture without the need for complex modifications.

Installation Process

Installing the Electronic Control Module Bracket requires attention to detail and adherence to specific steps to ensure proper functionality. The process involves securing the bracket in the designated location within the truck’s engine compartment, followed by mounting the ECM onto the bracket. Necessary tools for this installation may include torque wrenches and screwdrivers, depending on the specific model. It is important to follow the manufacturer’s guidelines to ensure the bracket is installed correctly and securely.

Maintenance and Troubleshooting

Maintaining the Electronic Control Module Bracket is straightforward, primarily involving regular inspections for signs of wear or damage. Ensuring that the bracket remains securely fastened and that the ECM is properly seated are key maintenance practices. Common issues may include loosening of the bracket or damage from environmental factors. Troubleshooting steps involve checking the bracket’s condition, ensuring all fasteners are tight, and verifying the ECM’s connection and operation.

Integration with Truck Systems

The Electronic Control Module Bracket is designed to interact seamlessly with other truck systems and components. Its role in securing the ECM ensures that the electronic system operates within the vehicle’s architecture without interference. This integration is crucial for the harmonious operation of the truck’s various systems, contributing to overall vehicle performance and reliability.

Manufacturer - Cummins

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product range extends beyond engines to include filtration, emissions, powertrain, and other components, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to excellence is reflected in every product it manufactures, including the Electronic Control Module Bracket.

Cummins Electronic Control Module Bracket (Part 3933468)

The Cummins Electronic Control Module (ECM) Bracket, identified by part number 3933468, is a critical component in the installation and operation of the ECM within various Cummins engine models. This bracket ensures the ECM is securely mounted and properly positioned, facilitating optimal performance and reliability.

Application in Cummins Engines

The ECM Bracket 3933468 is designed to fit seamlessly with several Cummins engine models, including but not limited to:

- B5.9 G Series: This bracket is engineered to integrate with the B5.9 G engine, ensuring the ECM is mounted in a manner that maintains the integrity of the engine’s electrical and control systems. The precise fitment of this bracket is crucial for the engine’s overall functionality, as it supports the ECM’s role in managing engine performance and diagnostics.

The ECM Bracket 3933468 is a testament to Cummins’ commitment to providing reliable and durable components that enhance the operational efficiency of their engines. Its design and material quality ensure that it can withstand the rigors of engine operation, providing a stable and secure mounting solution for the ECM.

Role of Part 3933468 Electronic Control Module Bracket in Engine Systems

In modern engine systems, the Electronic Control Module (ECM) is a pivotal component responsible for managing various engine functions. The ECM requires a secure and stable mounting solution to ensure optimal performance and longevity. This is where the Electronic Control Module Bracket, specifically part 3933468, comes into play.

The ECM Bracket serves as the foundational support for the ECM, ensuring it remains firmly in place within the engine compartment. This Cummins part is engineered to withstand the vibrations and harsh conditions typical of an engine environment, thereby protecting the sensitive electronic components of the ECM.

When the ECM is securely mounted using the ECM Bracket, it can effectively communicate with other engine control components such as sensors, actuators, and the engine control unit (ECU). This reliable connection ensures that the ECM can accurately monitor engine parameters, such as temperature, pressure, and fuel injection timing, and make real-time adjustments to optimize engine performance.

Furthermore, the ECM Bracket facilitates easier access to the ECM for maintenance and diagnostic purposes. Engineers and mechanics can quickly locate and interact with the ECM without the risk of it becoming dislodged or damaged due to improper mounting. This accessibility is vital for routine checks, software updates, and troubleshooting any potential issues that may arise.

Conclusion

In summary, the ECM Bracket, part 3933468, plays a significant role in maintaining the integrity and functionality of the ECM within the engine system. Its robust design ensures that the ECM remains securely in place, allowing for precise control and monitoring of engine operations, ultimately contributing to the overall efficiency and reliability of the engine.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.