This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Ground Wire 3954204 is a specialized component designed for use in commercial truck electrical systems. Its purpose is to provide a reliable ground connection, which is vital for the proper functioning of the vehicle’s electrical components. This part plays a role in ensuring the safety and efficiency of the truck’s electrical system by facilitating the return path for electrical current 1.

Basic Concepts of Ground Wires

Ground wires are integral to electrical systems, serving as a pathway for electrical current to return to the source, typically the battery. They contribute to the safe and efficient operation of vehicles by ensuring that electrical components receive a stable and consistent flow of electricity. Ground wires also play a role in protecting the vehicle and its occupants from electrical faults by providing a safe path for excess current to dissipate 2.

Purpose of Cummins Ground Wire 3954204

The Cummins Ground Wire 3954204 is specifically designed to connect various electrical components within a truck’s system to the vehicle’s chassis or another grounding point. This connection ensures that electrical current can flow efficiently and safely throughout the system. By providing a stable ground, this wire helps maintain the performance and reliability of the truck’s electrical components 3.

Key Features

The Cummins Ground Wire 3954204 is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design specifications include a robust gauge that can handle the electrical demands of commercial trucks. Additionally, the wire features secure connection points that facilitate easy installation and reliable performance 4.

Benefits of Using Cummins Ground Wire 3954204

Utilizing the Cummins Ground Wire 3954204 offers several advantages. It provides improved electrical conductivity, ensuring that components receive a consistent flow of electricity. This enhances the safety and reliability of the truck’s electrical system, particularly in demanding operating conditions. The wire’s durable construction also contributes to its longevity, reducing the need for frequent replacements 5.

Installation Considerations

Proper installation of the Cummins Ground Wire 3954204 is crucial for its effective performance. Best practices include ensuring a clean and corrosion-free connection point, using the appropriate tools for secure fastening, and verifying that the wire is routed away from moving parts and high-temperature areas. Awareness of potential challenges, such as tight spaces or existing wiring configurations, can help facilitate a smooth installation process 6.

Troubleshooting Common Issues

Common problems associated with ground wires in commercial trucks include poor connections, corrosion, and physical damage. To diagnose and resolve these issues, it is important to conduct regular inspections, clean connection points, and replace damaged sections of the wire as needed. Ensuring that the ground wire is securely fastened and free from obstructions can also help prevent issues 7.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins Ground Wire 3954204, regular maintenance is recommended. This includes inspecting the wire for signs of wear or damage, cleaning connection points to prevent corrosion, and ensuring that all connections are secure. If significant wear or damage is observed, consideration should be given to replacing the wire to maintain the integrity of the electrical system 8.

Safety Precautions

When working with electrical components like the Cummins Ground Wire 3954204, it is important to observe safety measures. This includes ensuring that the vehicle’s battery is disconnected before beginning any work, using insulated tools to prevent electrical shocks, and adhering to all safety protocols and guidelines provided by the manufacturer. Proper handling and installation of the ground wire are crucial to maintaining a safe working environment 9.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial vehicle industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to excellence is evident in its continuous investment in research and development, ensuring that its products meet the evolving needs of the industry 10.

Ground Wire 3954204 Compatibility with Cummins Engines

The Ground Wire part number 3954204, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for ensuring proper electrical grounding, which is essential for the safe and efficient operation of the engine. Below is a detailed description of the engines with which this ground wire is compatible.

ISB Series

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

The ISB series engines, including the ISB CM2150 and ISB CM850, benefit from the Ground Wire 3954204. This part ensures that the electrical systems within these engines are properly grounded, reducing the risk of electrical faults and improving overall performance.

ISBE Series

- ISBE4 CM850

The ISBE4 CM850 engine also integrates the Ground Wire 3954204. This ensures that the electrical components of the engine are securely grounded, contributing to the engine’s reliability and efficiency.

ISC Series

- ISC CM2150

- ISC CM850

The ISC series engines, such as the ISC CM2150 and ISC CM850, utilize the Ground Wire 3954204 to maintain proper electrical grounding. This is critical for the engine’s electrical systems to function correctly and safely.

ISL Series

- ISL CM2150

- ISL9 CM2150 SN

The ISL series engines, including the ISL CM2150 and ISL9 CM2150 SN, are designed to work with the Ground Wire 3954204. This part ensures that the electrical systems within these engines are properly grounded, enhancing their operational integrity.

ISM Series

- ISM CM570/870

- ISM CM876

The ISM series engines, such as the ISM CM570/870 and ISM CM876, are compatible with the Ground Wire 3954204. This ensures that the electrical components of these engines are securely grounded, contributing to their reliability and efficiency.

QSB Series

- QSB4.5 CM850(CM2850)

- QSB5.9 CM850

- QSB6.7 CM850(CM2850)

- QSC8.3 CM850(CM2850)

The QSB series engines, including the QSB4.5 CM850, QSB5.9 CM850, QSB6.7 CM850, and QSC8.3 CM850, are designed to work with the Ground Wire 3954204. This ensures that the electrical systems within these engines are properly grounded, enhancing their operational integrity.

QSK Series

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

The QSK series engines, such as the QSK19 CM850, QSK38 CM2150, QSK50 CM2150, and QSK60 CM850, are compatible with the Ground Wire 3954204. This ensures that the electrical components of these engines are securely grounded, contributing to their reliability and efficiency.

QSL Series

- QSL8.9 CM2150 L141

- QSL9 CM850(CM2850)

The QSL series engines, including the QSL8.9 CM2150 and QSL9 CM850, are designed to work with the Ground Wire 3954204. This ensures that the electrical systems within these engines are properly grounded, enhancing their operational integrity.

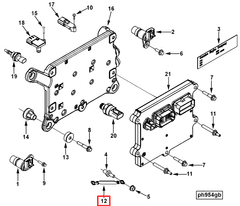

Ground Wire Component Usage

The Ground Wire, part 3954204, is an essential component in ensuring the proper functioning of various engine systems. Its role is to provide a reliable electrical path to the ground, which is necessary for the efficient operation of several engine components.

In the arrangement of the engine, the Ground Wire is strategically positioned to connect the engine’s electrical components to the vehicle’s chassis or a designated grounding point. This ensures that any electrical current has a safe and efficient route to return to the ground, minimizing the risk of electrical interference and ensuring stable operation of the engine systems.

The valve cover and cover components often house various sensors and electrical connections. The Ground Wire is integral in these areas, providing a ground connection for sensors such as the camshaft position sensor and the crankshaft position sensor. This grounding ensures accurate data transmission from these sensors to the Engine Control Module (ECM), allowing for precise engine timing and performance.

Within the valve system, the Ground Wire supports the operation of solenoids and actuators that control valve timing and lift. Proper grounding is essential for these components to function correctly, ensuring optimal airflow into and out of the combustion chambers, which directly impacts engine efficiency and power output.

The module, particularly the Engine Control Module (ECM), relies on a solid ground connection to process data from various sensors and execute commands to the engine’s actuators. The Ground Wire ensures that the ECM receives clean, interference-free signals, allowing it to make accurate adjustments to fuel injection, ignition timing, and other critical parameters.

Lastly, the Ground Wire plays a significant role in the overall engine control system. By providing a consistent ground reference, it helps maintain the integrity of the electrical signals throughout the engine’s control circuitry. This is vital for the coordination of all engine components, ensuring smooth and reliable operation under varying driving conditions.

Conclusion

The Cummins Ground Wire 3954204 is a critical component in the electrical systems of commercial trucks, ensuring reliable grounding for various engine components. Its high-quality construction, compatibility with a wide range of Cummins engines, and essential role in maintaining the integrity of electrical signals make it a valuable part for ensuring the safety, efficiency, and performance of truck electrical systems.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.