This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4010525 Electrical Connector is a specialized component designed for use in commercial truck operations. This connector facilitates the secure and efficient transmission of electrical signals and power within the truck’s electrical system. Its role is significant in ensuring the reliable operation of various electrical components and systems within the vehicle 1.

Basic Concepts of Electrical Connectors

Electrical connectors are devices used to join electrical circuits together, allowing the transfer of electrical signals and power. They are integral to the functionality of vehicle electrical systems, ensuring that components such as lights, sensors, and control units can communicate and operate effectively. The design and quality of these connectors are crucial for maintaining the integrity and efficiency of the electrical system 2.

Purpose of the 4010525 Electrical Connector

The Cummins 4010525 Electrical Connector serves a specific function within the truck’s electrical system. It is designed to connect and disconnect electrical circuits securely, ensuring that power and signals are transmitted without interruption. This connector plays a role in maintaining the operational efficiency of the truck’s electrical components, contributing to the overall performance and reliability of the vehicle 3.

Key Features

The Cummins 4010525 Electrical Connector is characterized by several key features that enhance its performance. Its design incorporates robust materials that provide durability and resistance to environmental factors. The connector is engineered to ensure a secure fit, minimizing the risk of disconnection or signal interference. Additionally, it features protective elements that safeguard against moisture and debris, ensuring consistent performance in various operating conditions.

Benefits

The use of the Cummins 4010525 Electrical Connector offers several advantages. It contributes to improved reliability within the truck’s electrical system, ensuring that components operate as intended. The connector’s design enhances efficiency by providing a stable connection that minimizes energy loss. Furthermore, its durability ensures long-term performance, reducing the need for frequent replacements and maintenance.

Installation and Usage

Proper installation of the Cummins 4010525 Electrical Connector is vital for ensuring its effectiveness. It should be installed according to manufacturer guidelines, with attention to securing the connection and protecting it from environmental factors. Users should follow best practices for handling and installation to ensure safety and optimal performance. Regular checks should be conducted to ensure the connector remains secure and functional.

Troubleshooting and Maintenance

Common issues with electrical connectors can include loose connections, corrosion, or damage from environmental factors. Troubleshooting may involve inspecting the connector for signs of wear or damage, ensuring it is securely connected, and cleaning or replacing it as necessary. Regular maintenance, such as checking for corrosion and ensuring the connector is free from debris, can help prevent issues and ensure consistent performance.

Compatibility and Applications

The Cummins 4010525 Electrical Connector is designed for use in specific types of trucks and electrical systems. Its applications vary across different commercial truck models, where it plays a role in ensuring the efficient operation of electrical components. Compatibility with specific systems ensures that the connector can effectively integrate into the truck’s electrical architecture, contributing to overall vehicle performance.

Safety Considerations

When working with the Cummins 4010525 Electrical Connector, it is important to adhere to safety protocols. This includes ensuring the electrical system is de-energized before installation or maintenance to prevent electrical shock. Additionally, users should wear appropriate personal protective equipment and follow manufacturer guidelines for handling and installation to ensure safety and effectiveness.

Cummins Overview

Cummins Inc. is a leading manufacturer of high-quality automotive components, including electrical connectors. With a history of innovation and excellence, Cummins plays a significant role in the automotive industry, providing components that contribute to the efficiency, reliability, and performance of vehicles. The company’s commitment to quality and customer satisfaction is evident in its wide range of products, designed to meet the demanding requirements of commercial and industrial applications.

Cummins Electrical Connector Part 4010525 in Engine Applications

The Cummins Electrical Connector part number 4010525 is a critical component in the electrical systems of various Cummins engines. This part is designed to ensure reliable and efficient electrical connections, which is essential for the proper functioning of the engine’s electronic control units (ECUs) and other electrical components.

QSK19 CM500 Engines

In the QSK19 CM500 engines, the Electrical Connector part 4010525 plays a pivotal role in maintaining the integrity of the electrical connections. These engines are known for their robust performance and are often used in heavy-duty applications, such as marine and industrial settings. The connector ensures that the electrical signals are transmitted accurately and without interruption, which is crucial for the engine’s performance and longevity.

Integration and Functionality

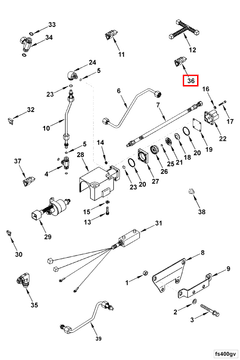

The integration of the Electrical Connector part 4010525 in the QSK19 CM500 engines involves precise placement and secure attachment. This part is typically located in areas where electrical connections are most vulnerable to wear and tear, such as in the engine’s control module or other critical junctions. Its design ensures that it can withstand the harsh conditions often encountered in heavy-duty environments, including high temperatures and vibrations.

The connector’s role in the engine’s electrical system is to facilitate the flow of electrical current between various components. This includes the ECU, sensors, and actuators, which all rely on accurate and timely electrical signals to operate correctly. The part’s robust construction and reliable performance are essential for maintaining the engine’s overall efficiency and reliability.

Importance in Engine Performance

The Electrical Connector part 4010525 is integral to the engine’s performance because it ensures that the electrical pathways remain uninterrupted. Any failure or degradation of this connector can lead to issues such as intermittent electrical faults, reduced engine performance, and potential safety hazards. Therefore, regular inspection and maintenance of this part are crucial to ensure the engine operates at its best.

Role of Part 4010525 Electrical Connector in Engine Systems

Integration with Accessories

The 4010525 Electrical Connector is instrumental in establishing reliable electrical connections between various accessories and the engine’s electrical system. This ensures that components such as alternators, starters, and sensors receive consistent power, facilitating their optimal operation. The connector’s robust design supports the transfer of electrical signals and power, which is essential for the accessories to function correctly and contribute to the overall performance and reliability of the engine system.

Functionality in the Fuel System

Within the fuel system, the 4010525 Electrical Connector plays a significant role by linking fuel injectors, fuel pumps, and sensors to the engine’s control unit. This connection is vital for the precise delivery of fuel, which directly impacts engine efficiency and emissions. The connector ensures that the fuel system components receive the necessary electrical signals to operate in sync with the engine’s requirements, thereby enhancing fuel economy and reducing harmful emissions.

Contribution to Hot Start and Knock Kit Systems

The 4010525 Electrical Connector is also integral to the operation of hot start and knock detection kits. These systems rely on accurate electrical connections to monitor engine conditions and make real-time adjustments. The connector facilitates the transmission of data from sensors to the engine control unit, allowing for timely interventions that prevent engine knock and ensure smooth starts even under challenging conditions. This not only protects the engine from potential damage but also improves its longevity and performance.

Conclusion

The Cummins 4010525 Electrical Connector is a vital component in the electrical systems of commercial trucks and Cummins engines. Its robust design, reliable performance, and integration with various engine systems ensure the efficient and reliable operation of electrical components. Regular maintenance and proper installation are essential to maximize the benefits of this connector, contributing to the overall performance and reliability of the vehicle.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.