4014523

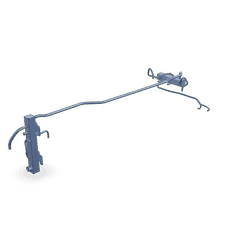

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4014523 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a prominent name in the commercial truck industry. This wiring harness is significant in the operation of commercial trucks, facilitating the communication and power distribution necessary for the truck’s electronic systems to function efficiently.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a collection of wires and connectors that link various electronic components within a truck’s electrical system. It includes multiple wires, connectors, and sometimes protective sheathing. The harness plays a role in transmitting signals and power between the Electronic Control Module (ECM) and other electronic components, ensuring that the truck’s systems operate in unison 1.

Role of the 4014523 Electronic Control Module Wiring Harness in Truck Operation

The 4014523 Wiring Harness is integral to the operation of a commercial truck. It connects the ECM to various sensors, actuators, and other electronic components throughout the vehicle. This connection allows the ECM to monitor and control engine performance, transmission operations, and other critical systems. The harness facilitates the flow of data and power, enabling the ECM to make real-time adjustments for optimal truck performance 2.

Key Features of the 4014523 Wiring Harness

The 4014523 Wiring Harness is designed with several features that enhance its performance and durability. It is constructed using high-quality materials resistant to wear, corrosion, and environmental factors. The harness is engineered to fit precisely within the truck’s architecture, reducing the risk of damage from movement or external forces. Additionally, it includes protective sheathing to safeguard the wires from physical damage and environmental exposure 3.

Benefits of Using the 4014523 Wiring Harness

Utilizing the 4014523 Wiring Harness offers several advantages. Its robust design and high-quality materials contribute to improved reliability and durability. The harness is also designed for ease of installation, with clear labeling and color-coded wires to simplify the process. Furthermore, its efficient design helps reduce the risk of electrical issues, contributing to the overall efficiency and performance of the truck.

Installation Process

Installing the 4014523 Wiring Harness involves several steps. First, ensure the truck’s electrical system is disconnected to prevent any risk of electrical shock. Then, route the harness through the designated pathways within the truck, ensuring it is secured in place to prevent movement. Connect the harness to the ECM and other components, following the provided wiring diagram. Finally, test the connections to ensure they are secure and functioning correctly.

Troubleshooting Common Issues

Common issues with the 4014523 Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by inspecting the harness for any visible damage. Check all connections to ensure they are secure and free from corrosion. If an issue is identified, repair or replace the affected section of the harness as necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 4014523 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, cleaning the connections to remove any corrosion, and ensuring all connections remain secure. Additionally, protecting the harness from physical damage and environmental exposure can help extend its lifespan.

About Cummins

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of products, including engines, filtration systems, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance components that contribute to the efficiency and durability of commercial trucks.

Cummins Engine Part 4014523: Electronic Control Module Wiring Harness

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4014523, is a critical component in the Cummins QSK60G engine. This wiring harness is designed to facilitate the electrical communication between the ECM and various sensors, actuators, and control units within the engine system.

In the Cummins QSK60G engine, the ECM Wiring Harness ensures that the ECM can effectively monitor and control engine performance parameters. This includes managing fuel injection timing, air intake, and exhaust emissions, among other functions. The harness is engineered to withstand the harsh operating conditions typical of heavy-duty engines, ensuring reliable and consistent performance.

This Cummins part is integral to the engine’s overall functionality, as it provides the necessary electrical pathways for the ECM to execute its control functions. This wiring harness is meticulously designed to ensure minimal electrical resistance and maximum signal integrity, which is crucial for the precise operation of the engine.

For the Cummins QSK60G engine, the ECM Wiring Harness is a key component that supports the engine’s advanced electronic control systems. Its design and placement within the engine architecture are critical to maintaining the engine’s efficiency and reliability.

Role of Part 4014523 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4014523, serves as the vital connective tissue within an engine system, facilitating seamless communication and power distribution between the Engine Control Module (ECM) and various engine components.

This wiring harness is engineered to interface with the ECM, which is the brain of the engine system, responsible for processing data from numerous sensors and actuators to optimize engine performance, fuel efficiency, and emissions control.

The harness connects to a multitude of components including:

-

Sensors: Such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. These sensors provide real-time data to the ECM about air intake, fuel mixture, and exhaust emissions.

-

Actuators: Including the fuel injectors, throttle body, and various solenoids. These components receive commands from the ECM to adjust fuel delivery, air intake, and other parameters to maintain optimal engine operation.

-

Ignition System: The harness links to the ignition coil(s) and spark plugs, ensuring precise timing of spark delivery for efficient combustion.

-

Emission Control Devices: Connections to the Exhaust Gas Recirculation (EGR) valve and catalytic converter allow the ECM to manage emissions in compliance with environmental regulations.

-

Ancillary Systems: Integration with the vehicle’s battery, alternator, and starter motor ensures that the ECM receives consistent power and can initiate engine start-up sequences.

By providing a robust and reliable electrical pathway, the ECM Wiring Harness ensures that all these components work in harmony, allowing the ECM to execute its role effectively in managing the engine’s operation.

Conclusion

The 4014523 Electronic Control Module Wiring Harness by Cummins is a critical component in the operation of commercial trucks and engines. Its role in facilitating communication and power distribution between the ECM and various electronic components ensures the efficient and reliable performance of the vehicle. With its robust design, high-quality materials, and ease of installation, this part contributes significantly to the overall functionality and durability of the truck’s electronic systems.

-

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.