4014524

Electronic Control Module Wiring Harness

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4014524 Electronic Control Module Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, is known for its high-quality and reliable parts. This Cummins part is designed to facilitate the electrical connections necessary for the proper functioning of a truck’s Electronic Control Module (ECM) and other critical systems.

Basic Concepts of Electronic Control Module Wiring Harness

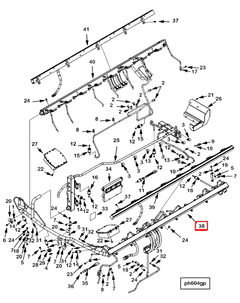

An Electronic Control Module Wiring Harness is a collection of wires, connectors, and terminals that transmit electrical signals between the ECM and various components of the truck. It consists of insulated wires bundled together, connectors that join different sections of the harness, and terminals that make the actual electrical connections. This harness plays a role in the truck’s electrical system by ensuring that all components receive the necessary signals to operate correctly 1.

Role of the 4014524 Electronic Control Module Wiring Harness in Truck Operation

The 4014524 Wiring Harness is integral to the operation of a commercial truck. It facilitates communication between the ECM and other systems, such as the engine, transmission, and braking systems. By providing a reliable pathway for electrical signals, the harness ensures that the ECM can monitor and control various truck functions, contributing to overall performance and efficiency 2.

Key Features of the 4014524 Wiring Harness

The 4014524 Wiring Harness is characterized by several key features that enhance its functionality and durability. These include a robust design that withstands the harsh conditions of commercial truck environments, high-quality materials that ensure longevity, and precise engineering that allows for seamless integration with other truck systems. Additionally, the harness is designed for ease of installation, reducing downtime during maintenance procedures 3.

Benefits of Using the 4014524 Wiring Harness

Utilizing the 4014524 Wiring Harness offers several benefits. Its durable construction and high-quality materials contribute to improved reliability, reducing the likelihood of electrical failures. The efficient design of the harness enhances the overall performance of the truck’s electrical system, leading to better fuel efficiency and reduced maintenance costs. Furthermore, the ease of installation minimizes downtime, allowing trucks to return to service quickly.

Troubleshooting the 4014524 Wiring Harness

When issues arise with the 4014524 Wiring Harness, systematic troubleshooting is necessary. Common problems may include loose connections, damaged wires, or faulty terminals. Diagnostic steps involve inspecting the harness for visible damage, testing electrical continuity, and using diagnostic tools to identify specific issues. Potential solutions range from repairing or replacing damaged sections to ensuring all connections are secure.

Maintenance of the 4014524 Wiring Harness

Regular maintenance of the 4014524 Wiring Harness is crucial for ensuring its longevity and optimal performance. Maintenance procedures include periodic inspection for signs of wear or damage, cleaning the harness to remove dirt and debris that could interfere with electrical connections, and ensuring all connections are tight and secure. Adhering to a maintenance schedule helps prevent unexpected failures and extends the life of the harness.

Integration with Other Systems

The 4014524 Wiring Harness is designed to integrate seamlessly with other truck systems, including the engine, transmission, and braking systems. This integration is vital for the harmonious operation of the truck, as it allows the ECM to monitor and control these systems effectively. The importance of this integration lies in its contribution to the truck’s overall performance, safety, and efficiency.

Safety Considerations

When installing, maintaining, or troubleshooting the 4014524 Wiring Harness, safety considerations are paramount. Proper handling of the harness is necessary to avoid damage to the wires and connectors. Electrical safety practices, such as ensuring the truck’s battery is disconnected before working on the harness, are crucial to prevent electrical shocks or fires. Adhering to safety guidelines protects both the technician and the truck’s electrical system.

Common Misconceptions

There are several misconceptions about Electronic Control Module Wiring Harnesses, including the belief that they are universally interchangeable or that they require frequent replacement. It is important to clarify that wiring harnesses are designed for specific applications and should not be interchanged without proper verification. Additionally, with proper maintenance, the 4014524 Wiring Harness can provide reliable service for an extended period, contrary to the belief that it needs frequent replacement.

About Cummins

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance. The company’s product range includes engines, transmissions, and various components designed to enhance the efficiency and durability of commercial trucks. Cummins’ commitment to quality and customer satisfaction has made it a preferred choice among truck manufacturers and operators.

Application in Cummins Engines

The ECM Wiring Harness is integral to the proper functioning of the engine’s electronic control systems. It ensures that the ECM can effectively communicate with other electronic components, thereby optimizing engine performance, fuel efficiency, and emissions control.

Specific Engine Models

- QSK60G: This engine model, part of Cummins’ QSK series, is a high-performance, heavy-duty diesel engine. The ECM Wiring Harness in this engine is designed to handle the complex electrical demands of the QSK60G, ensuring reliable and efficient communication between the ECM and the engine’s various subsystems.

The ECM Wiring Harness is engineered to withstand the harsh conditions of engine operation, including high temperatures, vibrations, and exposure to engine fluids. Its robust design and precise wiring ensure that the ECM can accurately monitor and control engine parameters, contributing to the overall reliability and performance of the engine.

Role of Part 4014524 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module Wiring Harness (Part 4014524) is integral to the seamless operation of modern engine systems. This component acts as the central nervous system, facilitating communication between the Engine Control Module (ECM) and various other components within the engine assembly.

Integration with the Engine Control Module

The ECM relies on the wiring harness to transmit signals and data to and from the engine’s sensors and actuators. This ensures that the ECM receives accurate, real-time data about the engine’s performance, allowing it to make precise adjustments to fuel injection, ignition timing, and other critical parameters. The harness also enables the ECM to send commands to components such as the fuel injectors, ignition coils, and variable valve timing systems, ensuring that the engine operates efficiently and within specified parameters.

Connection to the Wiring Top Level Assembly Harness

The wiring top level assembly harness serves as the primary distribution network for electrical signals throughout the engine bay. Part 4014524 interfaces directly with this assembly, providing a dedicated pathway for the ECM’s signals. This connection ensures that all subsystems, including the fuel system, ignition system, and emissions control system, receive the necessary instructions from the ECM. The wiring harness also incorporates protective measures such as shielding and insulation to safeguard against electrical interference and environmental factors, ensuring reliable signal transmission.

Enhanced System Performance

By providing a robust and organized pathway for electrical signals, Part 4014524 enhances the overall performance and reliability of the engine system. It allows for quicker response times, improved fuel efficiency, and reduced emissions. Additionally, the harness simplifies the diagnostic process by offering clear pathways for troubleshooting electrical issues, thereby reducing downtime and maintenance costs.

Conclusion

In summary, the Electronic Control Module Wiring Harness (Part 4014524) plays a significant role in maintaining the intricate balance of modern engine systems, ensuring that all components work harmoniously under the ECM’s control. Its robust design, precise engineering, and seamless integration with other systems contribute to the overall performance, safety, and efficiency of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.