This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

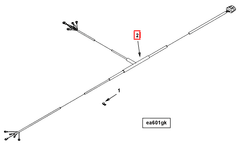

The Electronic Control Module Wiring Harness, identified by part number 4016921, is a component manufactured by Cummins, a well-established name in the automotive industry. This wiring harness is integral to the operation of heavy-duty trucks, facilitating the communication and power distribution necessary for the vehicle’s electronic systems to function efficiently.

Basic Concepts

Electronic Control Module Wiring Harnesses serve as the backbone of a vehicle’s electronic system, enabling communication between the Electronic Control Module (ECM) and various sensors, actuators, and other electronic components. These harnesses are designed to transmit signals and power, ensuring that all electronic systems within the vehicle operate in unison. They play a significant role in the vehicle’s overall electronics and communication infrastructure 1.

Functionality

This Cummins part operates by connecting the ECM to the truck’s electronic components. It facilitates the transmission of data and power, allowing the ECM to monitor and control various systems within the truck. This includes engine management, transmission control, and other critical functions. The harness is engineered to withstand the harsh environments typical of heavy-duty truck operations, ensuring reliable performance.

Key Features

The 4016921 is characterized by its robust design and high-quality construction. It features durable materials and precise engineering to ensure longevity and reliability. Specific technological attributes of this harness include enhanced signal integrity, resistance to environmental factors, and compatibility with a wide range of ECMs and truck models. These features contribute to its performance and reliability in demanding applications 2.

Benefits

The integration of this part into a truck’s electronic system offers several advantages. It contributes to improved engine performance by ensuring efficient communication between the ECM and engine components. Enhanced diagnostics capabilities are another benefit, as the harness allows for more accurate monitoring and troubleshooting of the truck’s electronic systems. Additionally, it increases overall system efficiency by optimizing the flow of data and power within the vehicle’s electronic network.

Installation and Integration

Proper installation and integration of the Electronic Control Module Wiring Harness are crucial for its effective operation. Guidelines for installation include ensuring compatibility with the specific truck model and ECM, following manufacturer instructions for connection and routing, and verifying all connections are secure and correctly aligned. Careful consideration of these factors will ensure the harness functions as intended within the truck’s electronic system.

Troubleshooting and Maintenance

Common issues with this part may include signal interference, connection failures, or damage from environmental factors. Diagnostic procedures involve checking for proper connections, inspecting the harness for physical damage, and using diagnostic tools to identify any communication errors. Regular maintenance, such as cleaning connections and inspecting the harness for wear, can help ensure optimal performance and longevity 3.

Safety Considerations

When working with the Electronic Control Module Wiring Harness, it is important to observe safety protocols to prevent electrical hazards and ensure personal safety. This includes disconnecting the battery before beginning any work on the harness, using insulated tools to avoid short circuits, and ensuring all connections are secure to prevent electrical arcing. Adhering to these safety considerations is vital when performing maintenance or repairs on the harness.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to producing high-quality components. With a history of innovation and excellence, Cummins has established itself as a leader in the design and production of automotive parts, including the 4016921 Electronic Control Module Wiring Harness. Their products are recognized for their reliability, performance, and durability, making them a preferred choice for heavy-duty truck applications.

Role of Part 4016921 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4016921, serves as the vital nervous system for modern engine systems, ensuring seamless communication and operation between various components.

Integration with Accessories

When integrating with accessories, the ECM Wiring Harness facilitates the connection between the ECM and peripheral devices such as air conditioning systems, power steering, and entertainment systems. This harness ensures that these accessories receive the necessary signals and power from the ECM, allowing them to operate efficiently and in sync with the engine’s performance. For instance, during high-load conditions, the harness can adjust the power distribution to accessories, ensuring that the engine maintains optimal performance.

Function in Electric Starting Systems

In electric starting systems, the ECM Wiring Harness plays a significant role by connecting the ECM to the starter motor and battery. It transmits the start signal from the ignition switch to the ECM, which then processes this signal and sends the appropriate command to the starter motor. This ensures a smooth and reliable start-up process. Additionally, the harness monitors the battery’s state of charge and health, providing the ECM with real-time data to make informed decisions about starting the engine, especially in conditions where the battery might be low or the engine is cold.

Conclusion

Overall, the ECM Wiring Harness is essential for the coordinated function of engine systems, enhancing both performance and reliability. Its robust design, compatibility with various ECMs and truck models, and role in facilitating efficient communication and power distribution make it a critical component in the operation of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.