This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

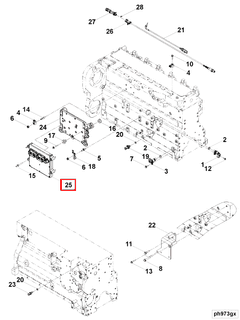

The 4354538 Electronic Control Module (ECM) by Cummins is a sophisticated component designed to enhance the operation of commercial trucks. It plays a role in optimizing engine performance and efficiency, ensuring that trucks operate at peak condition. This ECM is integral to the management of various engine functions, contributing to the overall reliability and effectiveness of the vehicle.

Basic Concepts of Electronic Control Modules

An Electronic Control Module (ECM) is a computerized device that manages and regulates the operations of a truck’s engine management system. It processes data from various sensors and actuators, making real-time adjustments to ensure optimal engine performance. The ECM operates on basic principles of data acquisition, processing, and control, allowing it to maintain engine efficiency and comply with emissions standards 2.

Purpose of the 4354538 ECM

The 4354538 ECM is specifically designed to manage and control various aspects of a truck’s engine. Its responsibilities include regulating fuel injection, monitoring engine temperature, and managing emissions. By overseeing these functions, the ECM ensures that the engine operates efficiently and within specified parameters, contributing to overall performance optimization 3.

Key Features

The 4354538 ECM boasts several key features that enhance its functionality. These include robust processing power, which allows for quick data analysis and decision-making, and a substantial memory capacity that stores critical data and software. Additionally, it offers various connectivity options, enabling seamless integration with other truck systems. Unique functionalities such as advanced diagnostics and real-time monitoring further distinguish this ECM 4.

Benefits of Using the 4354538 ECM

Utilizing the 4354538 ECM provides several advantages. It contributes to improved fuel efficiency by optimizing engine operations, leading to cost savings for fleet operators. Enhanced engine performance is another benefit, as the ECM ensures that the engine operates at its best under varying conditions. Better emissions control is achieved through precise management of fuel injection and exhaust systems. Increased reliability is also a notable advantage, as the ECM’s robust design and advanced features help prevent malfunctions and extend the engine’s lifespan 1.

Integration with Other Systems

The 4354538 ECM interacts with various components and systems within the truck, including the engine, transmission, and an array of sensors. This integration allows for comprehensive management of the engine’s functions, ensuring that all systems work in harmony to achieve optimal performance. The ECM communicates with sensors to gather data and with actuators to make necessary adjustments, creating a cohesive engine management system 2.

Troubleshooting Common Issues

Identifying and addressing common problems with the 4354538 ECM involves following specific diagnostic procedures. Issues may arise from software glitches, sensor malfunctions, or connectivity problems. Diagnostic tools and procedures are available to pinpoint the source of the problem, allowing for effective solutions such as software updates, sensor replacements, or reconfiguration of settings 3.

Maintenance Tips

To ensure the optimal performance and longevity of the 4354538 ECM, regular maintenance is recommended. This includes performing routine checks to ensure all connections are secure and the software is up to date. Best practices for handling and installation, such as avoiding exposure to extreme temperatures and ensuring proper grounding, are also important. Adhering to these maintenance tips helps prevent issues and ensures the ECM continues to operate efficiently 4.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to innovation and quality. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial trucking. Cummins’ dedication to advancing technology and improving efficiency underscores its position as a leader in the industry 1.

Cummins Electronic Control Module (ECM) Part 4354538

The Cummins Electronic Control Module (ECM) part 4354538 is a component designed to manage and optimize the performance of various Cummins engines. This ECM is engineered to work seamlessly with the following engines:

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is a high-performance, heavy-duty diesel engine known for its reliability and efficiency. The ECM part 4354538 is specifically tailored to interface with this engine, ensuring precise control over fuel injection, timing, and other vital functions. This integration allows for enhanced performance, improved fuel economy, and reduced emissions, making it an ideal choice for demanding applications.

B118

The B118 engine is another robust Cummins engine that benefits significantly from the ECM part 4354538. This ECM provides advanced diagnostic capabilities, ensuring that the engine operates at peak efficiency while maintaining optimal performance levels. The seamless integration of the ECM with the B118 engine ensures that all engine parameters are monitored and adjusted in real-time, contributing to the engine’s longevity and reliability.

Compatibility and Integration

The ECM part 4354538 is designed to be highly compatible with the specified Cummins engines, ensuring a smooth and efficient integration process. This compatibility is achieved through meticulous engineering and rigorous testing, guaranteeing that the ECM will work flawlessly with the engine’s hardware and software systems. The result is a harmonious operation that maximizes the engine’s potential and ensures consistent performance across various applications.

Role of Part 4354538 Electronic Control Module in Engine Systems

The Electronic Control Module (ECM), specifically part 4354538, is integral to the operation of modern engine systems. It serves as the brain of the engine, orchestrating a symphony of components to ensure optimal performance and efficiency.

Interaction with the Engine Control Module (ECM)

Part 4354538 ECM works in tandem with the Engine Control Module to manage fuel injection, ignition timing, and emissions control. It processes data from various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. This data is used to make real-time adjustments to the engine’s operation, ensuring it runs smoothly under varying conditions 2.

Communication with Other Components

The ECM communicates with several other components to maintain engine efficiency:

- Fuel Injectors: The ECM controls the fuel injectors by determining the precise amount of fuel to be injected into the combustion chamber based on engine load and speed.

- Ignition System: It manages the ignition timing by sending signals to the ignition coils, ensuring that the spark plugs fire at the optimal moment.

- Exhaust Gas Recirculation (EGR) Valve: The ECM regulates the EGR valve to reduce nitrogen oxides (NOx) emissions by recirculating a portion of the exhaust gas back into the intake manifold.

- Throttle Position Sensor (TPS): It receives input from the TPS to adjust the air-fuel mixture according to the driver’s throttle input.

- Camshaft and Crankshaft Position Sensors: These sensors provide the ECM with data on the position and speed of the camshaft and crankshaft, allowing for precise control of fuel injection and ignition timing 3.

Enhancing Performance and Efficiency

By integrating part 4354538 ECM into the engine system, the overall performance and efficiency of the engine are significantly enhanced. The ECM’s ability to make split-second adjustments based on real-time data ensures that the engine operates at its peak performance while minimizing emissions and fuel consumption.

This component is essential for maintaining the delicate balance required for modern engines to meet stringent emissions standards and deliver reliable performance across a wide range of operating conditions 4.

Conclusion

The 4354538 ECM by Cummins is a critical component in the operation of commercial trucks, enhancing engine performance, efficiency, and reliability. Its advanced features, seamless integration with other systems, and robust design make it an invaluable asset for fleet operators. Regular maintenance and proper handling ensure the longevity and optimal performance of this ECM, contributing to the overall success of commercial trucking operations.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ ↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ ↩ ↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ ↩ ↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.