This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4382572 Electronic Control Cooler by Cummins is a specialized component designed to enhance the efficiency and performance of commercial truck engines. This part is integral to maintaining optimal operating conditions within the engine system, ensuring that the truck operates smoothly and efficiently under various load conditions.

Basic Concepts of Electronic Control Coolers

An Electronic Control Cooler is a device that manages the temperature of electronic components within a truck’s engine management system. It functions by circulating coolant through a series of channels and passages, effectively dissipating heat generated by electronic control units (ECUs) and other sensitive components. This cooling mechanism is vital for maintaining the integrity and reliability of the engine’s electronic systems, which are responsible for controlling fuel injection, ignition timing, and other critical functions 1.

Purpose and Role in Truck Operation

The 4382572 Electronic Control Cooler plays a significant role in the operation of a truck by ensuring that the electronic control units remain within their optimal temperature range. This is particularly important in heavy-duty applications where the engine is subjected to high loads and varying operating conditions. By maintaining the ECUs at the correct temperature, the cooler helps to ensure consistent engine performance, improved fuel efficiency, and reduced risk of electronic failures 2.

Key Features

The 4382572 Electronic Control Cooler is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring long-term reliability. The cooler incorporates advanced cooling technologies, such as precision-machined channels and high-efficiency heat exchangers, to maximize cooling performance. Additionally, the design of the cooler allows for easy integration into existing engine systems, minimizing the complexity of installation 3.

Benefits

The benefits of the 4382572 Electronic Control Cooler include improved engine performance, enhanced durability of electronic components, and potential cost savings for fleet operators. By maintaining optimal operating temperatures, the cooler helps to ensure that the engine’s electronic systems function efficiently, leading to better overall performance and fuel economy. Additionally, the cooler’s robust construction and advanced cooling technologies contribute to the longevity of the electronic components, reducing the need for frequent replacements and repairs.

Installation and Integration

When installing the 4382572 Electronic Control Cooler, it is important to follow the manufacturer’s guidelines to ensure proper integration into the truck’s engine system. This includes verifying compatibility with the specific engine model, ensuring that all connections are secure, and confirming that the cooler is properly aligned with the engine’s cooling system. Careful attention to these details will help to ensure that the cooler operates effectively and provides the intended benefits.

Troubleshooting and Maintenance

Common issues that may arise with the 4382572 Electronic Control Cooler include coolant leaks, reduced cooling efficiency, and electronic failures. Troubleshooting these issues may involve checking for loose connections, inspecting the cooler for signs of damage or corrosion, and ensuring that the coolant system is functioning correctly. Regular maintenance practices, such as flushing the cooling system and inspecting the cooler for wear, can help to prevent these issues and ensure optimal performance.

Performance Monitoring

Monitoring the performance of the 4382572 Electronic Control Cooler can be achieved through various methods and tools. Diagnostic techniques, such as using temperature sensors and monitoring software, can provide real-time data on the cooler’s performance. Regular check-ups and inspections should be conducted to ensure that the cooler is operating within specified parameters and to identify any potential issues before they become critical.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. The company’s commitment to innovation and quality has made it a trusted name among fleet operators and manufacturers worldwide.

Electronic Control Cooler for Cummins Engines

The Electronic Control Cooler, part number 4382572, is a critical component designed to maintain optimal operating temperatures for the electronic control systems in certain Cummins engines. This part is specifically engineered to fit seamlessly with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, ensuring that the electronic control units (ECUs) remain within their specified temperature range.

Compatibility with QSK95 CM2350 K111 and QSK95 CM2350 K113

The Electronic Control Cooler is designed to integrate with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, providing a reliable cooling solution for the ECUs. These engines are known for their robust performance and reliability, and the cooler ensures that the electronic components operate efficiently under various conditions.

Installation and Functionality

The installation of the Electronic Control Cooler is straightforward, designed to fit precisely within the engine’s architecture. This cooler is typically mounted in a location that allows for efficient airflow and heat dissipation, ensuring that the ECUs do not overheat. The cooler works by drawing in ambient air, passing it over the heat-generating components, and then expelling the warmed air away from the sensitive electronics.

Importance of the Electronic Control Cooler

Maintaining the correct temperature for the ECUs is crucial for the overall performance and longevity of the engine. Overheating can lead to malfunctions, reduced efficiency, and potentially severe damage to the electronic systems. The Electronic Control Cooler helps prevent these issues by providing a consistent and reliable cooling mechanism.

Maintenance and Reliability

Regular maintenance of the Electronic Control Cooler is essential to ensure its continued effectiveness. This includes checking for any blockages or damage to the cooler and ensuring that it is properly mounted and secured. By keeping the cooler in good condition, operators can avoid unexpected downtime and ensure that their engines run smoothly and efficiently.

Role of Part 4382572 Electronic Control Cooler in Engine Systems

The 4382572 Electronic Control Cooler is an integral component in maintaining the efficiency and reliability of engine systems. It works in conjunction with several key components to ensure optimal performance.

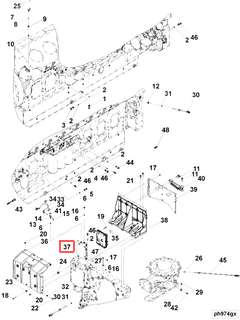

Integration with the Module

The Electronic Control Cooler is designed to interface directly with the engine’s control module. This module is responsible for monitoring and adjusting various engine parameters in real-time. The cooler ensures that the module operates within its specified temperature range, thereby preventing overheating which could lead to malfunctions or reduced efficiency. By maintaining a stable temperature, the cooler allows the module to deliver precise control signals to other engine components.

Interaction with the Engine Control System

In the engine control system, the Electronic Control Cooler plays a significant role in thermal management. It helps dissipate heat generated by the control electronics, which is vital for consistent engine performance. The cooler ensures that the engine control unit (ECU) remains within its optimal operating temperature, allowing it to execute commands accurately and efficiently. This is particularly important during high-load conditions where the ECU is heavily taxed.

Contribution to the Service Kit

When included in a service kit, the Electronic Control Cooler enhances the overall reliability of the engine system. Service kits are typically designed to address common wear and tear issues, and the addition of a cooler ensures that temperature-sensitive components are protected. This proactive approach to maintenance can prevent unexpected failures and extend the lifespan of the engine control system. Mechanics often recommend replacing the cooler as part of routine maintenance to ensure that the engine continues to perform at peak efficiency.

Conclusion

The 4382572 Electronic Control Cooler is a vital component that supports the module, engine control system, and is a valuable addition to any service kit. Its role in thermal management ensures that these components operate efficiently and reliably, contributing to the overall performance and longevity of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.